Principle, Construction, Working Principle, Diagram, Advantages - AC Generator | 12th Physics : Electromagnetic Induction and Alternating Current

Chapter: 12th Physics : Electromagnetic Induction and Alternating Current

AC Generator

AC GENERATOR

1. Introduction

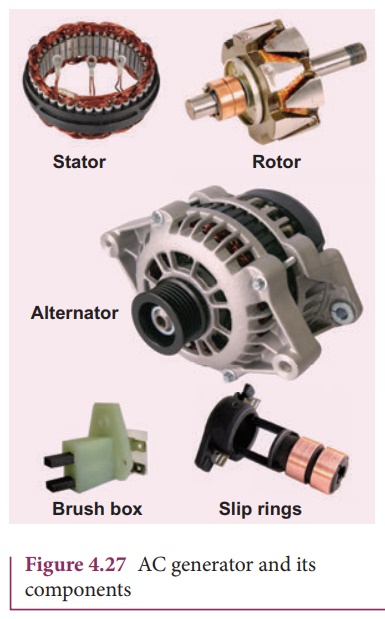

AC generator or

alternator is an energy conversion device. It converts mechanical energy used

to rotate the coil or field magnet into electrical energy. Alternator produces

a large scale electrical power for use in homes and industries. AC generator

and its components are shown in Figure 4.27.

2. Principle

Alternators work on the

principle of electromagnetic induction. The relative motion between a conductor

and a magnetic field changes the magnetic flux linked with the conductor which

in turn, induces an emf. The magnitude of the induced emf is given by Faraday’s

law of electromagnetic induction and its direction by Fleming’s right hand

rule.

3. Construction

Alternator consists of

two major parts, namely stator and rotor. As their names suggest, stator is

stationary while rotor rotates inside the stator. In any standard construction

of commercial alternators, the armature winding is mounted on stator and the

field magnet on rotor.

The construction details

of stator, rotor and various other components involved in them are given below.

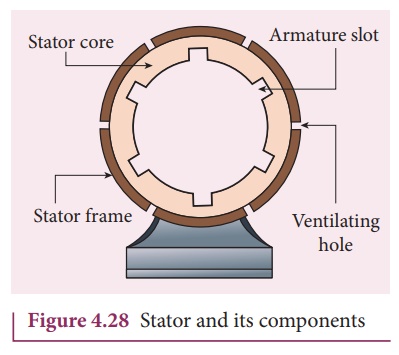

i) Stator

The stationary part

which has armature windings mounted in it is called stator. It has three

components, namely stator frame, stator core and armature winding.

Stator frame

This is the outer frame

used for holding stator core and armature windings in proper position. Stator

frame provides best ventilation with the help of holes provided in the frame

itself (Figure 4.28).

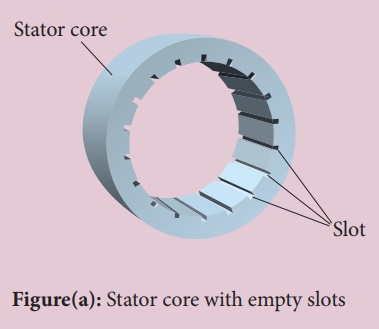

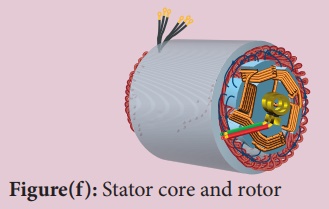

Stator core

Stator core or armature

core is made up of iron or steel alloy. It is a hollow cylinder and is

laminated to minimize eddy current loss. The slots are cut on inner surface of

the core to accommodate armature windings.

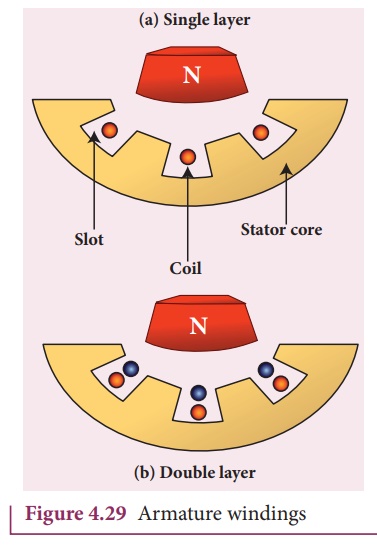

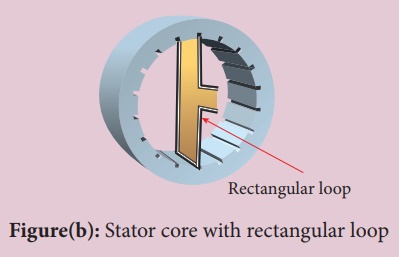

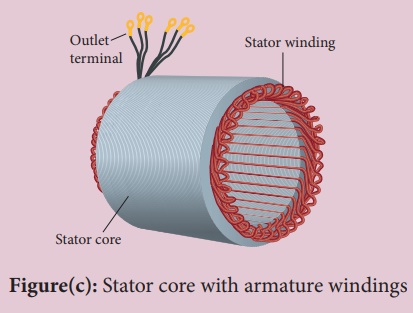

Armature winding

Armature winding is the

coil, wound on slots provided in the armature core. One or more than one coil

may be employed, depending on the type of alternator.

Two types of windings

are commonly used. They are i) single-layer winding and ii) double-layer

winding. In single-layer winding, a slot is occupied by a coil as a single layer.

But in double-layer winding, the coils are split into two layers such as top

and bottom layers (Figure 4.29).

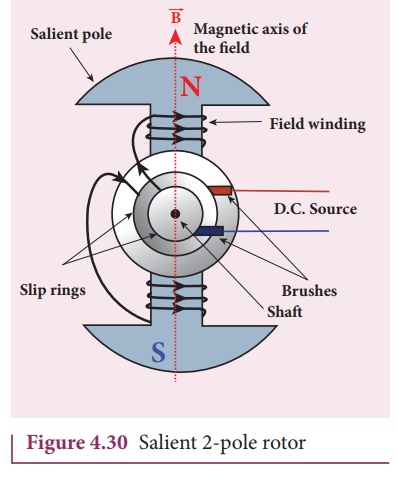

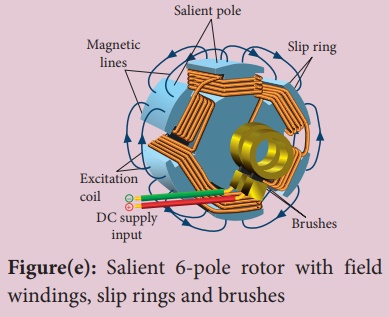

ii) Rotor

Rotor contains magnetic

field windings. The magnetic poles are magnetized by DC source. The ends of

field windings are connected to a pair of slip rings, attached to a common

shaft about which rotor rotates. Slip rings rotate along with rotor. To

maintain connection between the DC source and field windings, two brushes are

used which continuously slide over the slip rings.

There are 2 types of

rotors used in alternators i) salient pole rotor and ii) cylindrical pole

rotor.

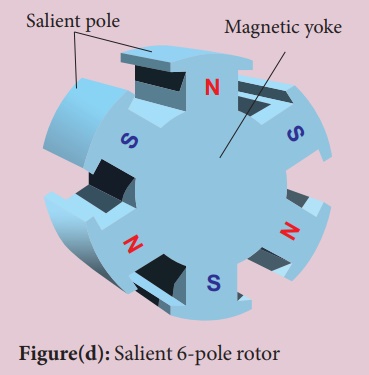

Salient pole rotor

The word salient means

projecting. This rotor has a number of projecting poles having their bases riveted

to the rotor. It is mainly used in low-speed alternators. The salient 2-pole

rotor is shown in the Figure 4.30.

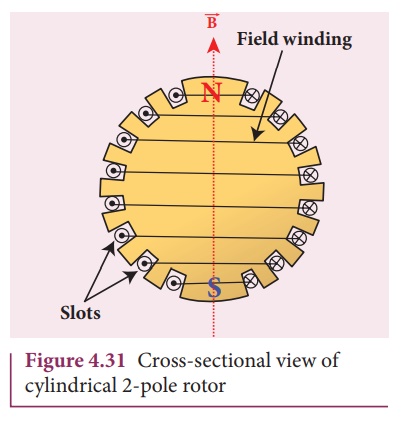

Cylindrical pole rotor

This rotor consists of a

smooth solid cylinder. The slots are cut on the outer surface of the cylinder

along its length. It is suitable for very high speed alternators (Figure 4.31).

The frequency of

alternating emf induced is directly proportional to the rotor speed. In order

to maintain the frequency constant, the rotor must run at a constant speed.

These are standard

construction details of alternators. Based on the type of alternator being

constructed, the details like number of poles, pole type, number of coils and

type of windings would change from one another.

We will discuss the

construction and working of two examples, namely single phase and three phase

AC generators in the following sections.

Construction of AC generator

Alternator consists of two major parts, namely stator and rotor. (This box is given for better understanding of constructional details)

i) Stator

Stator has three components, namely stator frame, stator core and armature winding.

ii) Rotor

Rotor contains magnetic field windings, slip rings and brushes mounted on the same shaft.

4. Advantages of stationary armature-rotating field alternator

Alternators are

generally high current and high voltage machines. The stationary armature-rotating

field construction has many advantages. A few of them include:

1) The current is

drawn directly from fixed terminals on the stator without the use of brush

contacts.

2) The insulation

of stationary armature winding is easier.

3) The number of sliding

contacts (slip rings) is reduced. Moreover, the sliding contacts are used for

low-voltage DC Source.

4) Armature

windings can be constructed more rigidly to prevent deformation due to any

mechanical stress.

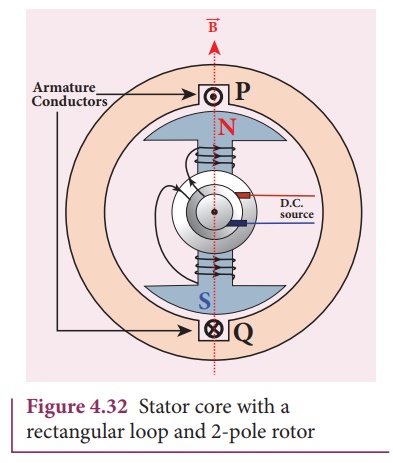

5. Single phase AC generator

In a single phase AC

generator, the armature conductors are connected in series so as to form a

single circuit which generates a single-phase alternating emf and hence it is

called single-phase alternator.

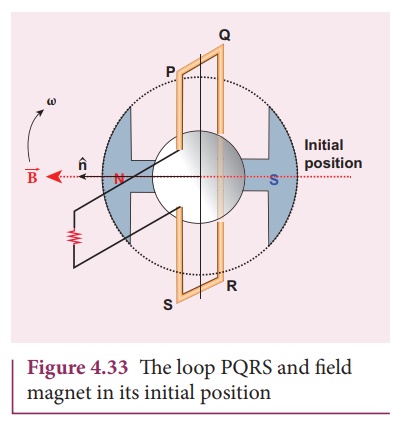

The simplified version

of a AC generator is discussed here. Consider a stator core consisting of 2

slots in which 2 armature conductors PQ and RS are mounted to form single-turn

rectangular loop PQRS as shown in Figure 4.33. Rotor has 2 salient poles with

field windings which can be magnetized by means of DC source.

Working

The loop PQRS is

stationary and is perpendicular to the plane of the paper. When field windings

are excited, magnetic field is produced around it. The direction of magnetic

field passing through the armature core is shown in Figure 4.33. Let the field

magnet be rotated in clockwise direction by the prime mover. The axis of

rotation is perpendicular to the plane of the paper.

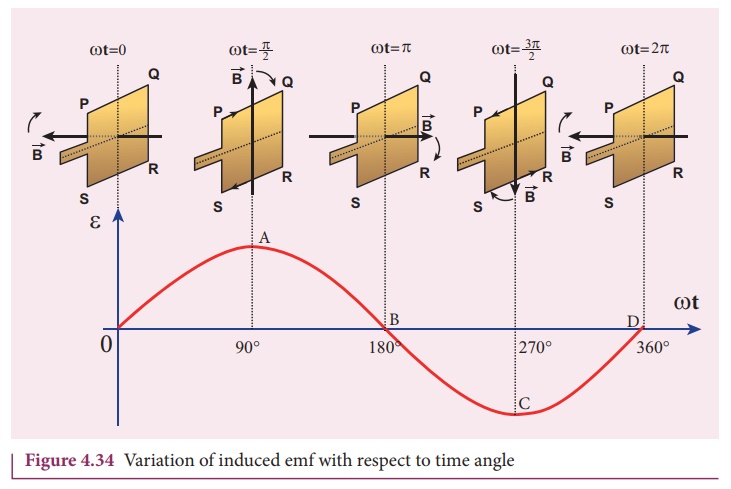

Assume that initial

position of the field magnet is horizontal. At that instant, the direction of

magnetic field is perpendicular to the plane of the loop PQRS. The induced emf

is zero (Refer case (iii) of section 4.4). This is represented by origin O in

the graph between induced emf and time angle (Figure 4.34).

When field magnet

rotates through 90°, magnetic field becomes parallel to PQRS. The induced emfs

across PQ and RS would become maximum. Since they are connected in series, emfs

are added up and the direction of total induced emf is given by Fleming’s right

hand rule.

Care has to be taken while

applying this rule; the thumb indicates the direction of the motion of the

conductor with respect to field. For clockwise rotating poles, the conductor

appears to be rotating anti-clockwise. Hence, thumb should point to the left.

The direction of the induced emf is at right angles to the plane of the paper.

For PQ, it is downwards and for RS upwards. Therefore, the current flows along

PQRS. The point A in the graph represents this maximum emf.

For the rotation of 180°

from the initial position, the field is again perpendicular to PQRS and the

induced emf becomes zero. This is represented by point B.

The field magnet becomes

again parallel to PQRS for 270° rotation of field magnet. The induced emf is

maximum but the direction is reversed. Thus the current flows along SRQP. This

is represented by point C.

On completion of 360°,

the induced emf becomes zero and is represented by the point D. From the graph,

it is clear that emf induced in PQRS is alternating in nature.

Therefore, when field magnet completes one rotation, induced emf in PQRS finishes one cycle. For this construction, the frequency of the induced emf depends on the speed at which the field magnet rotates.

6. Three-phase AC generator

Some AC generators may

have more than one coil in the armature core and each coil produces an

alternating emf. In these generators, more than one emf is produced. Thus they

are called poly-phase generators.

If there are two

alternating emfs produced in a generator, it is called two-phase generator. In

some AC generators, there are three separate coils, which would give three

separate emfs. Hence they are called three-phase AC generators.

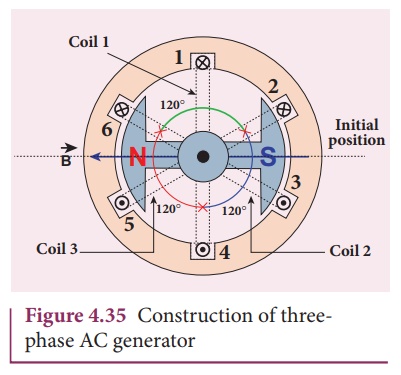

In the simplified

construction of three-phase AC generator, the armature core has 6 slots, cut on

its inner rim. Each slot is 60° away from one another. Six armature conductors

are mounted in these slots. The conductors 1 and 4 are joined in series to form

coil 1. The conductors 3 and 6 form coil 2 while the conductors 5 and 2 form

coil 3. So, these coils are retangular in shape and are 120° apart from one

another (Figure 4.35).

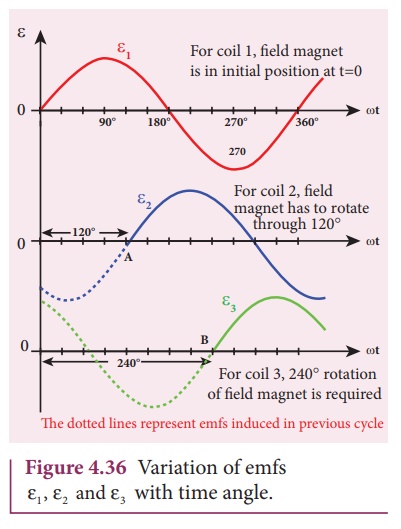

The initial position of

the field magnet is horizontal and field direction is perpendicular to the

plane of the coil 1. As it is seen in single phase AC generator, when field magnet

is rotated from that position in clockwise direction,

alternating emf ε1 in coil 1 begins a cycle from origin O. This is shown in Figure

4.36.![]()

![]()

The corresponding cycle

for alternating emf ε2 in coil 2 starts at point A after field magnet has rotated through

120°. Therefore, the phase difference between ε1 and ε2 is 120°. Similarly, emf ε3 in coil 3 would begin its cycle at point B after 240° rotation of

field magnet from initial position. Thus these emfs produced in the three phase

AC generator have 120° phase difference between one another.

7. Advantages of three-phase alternator

Three-phase system has

many advantages over single-phase system. Let us see a few of them.

1) For a given

dimension of the generator, three-phase machine produces higher power output

than a single-phase machine.

2) For the same

capacity, three-phase alternator is smaller in size when compared to single

phase alternator.

3) Three-phase

transmission system is cheaper. A relatively thinner wire is sufficient for

transmission of three-phase power.

Related Topics