Chapter: 11th Physics : UNIT 7 : Properties of Matter

HookeŌĆÖs law and its experimental verification

HookeŌĆÖs

law and its experimental verification

HookeŌĆÖs

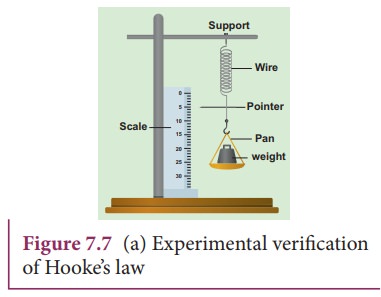

law is for a small deformation, when the stress and strain are proportional to

each other. It can be verified in a simple way by stretching a thin straight

wire (stretches like spring) of length L and uniform cross-sectional area A

suspended from a fixed point O. A pan and a pointer are attached at the free

end of the wire as shown in Figure 7.7 (a). The extension produced on the wire

is measured using a vernier scale arrangement. The experiment shows that for a

given load, the corresponding stretching force is F and the elongation produced

on the wire is ΔL. It is directly proportional to the original length L and

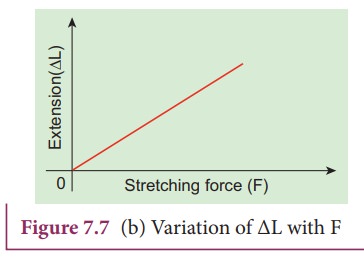

inversely proportional to the area of cross section A. A graph is plotted using

F on the X- axis and ΔL on the Y- axis. This graph is a straight line passing

through the origin as shown in Figure 7.7 (b).

Therefore,

ŌłåL = (slope)F

Multiplying

and dividing by volume,

V

= A L,

Comparing

with equation (7.1) and equation (7.2), we get equation (7.5) as

Žā ŌłØ ╬Ą

i.e.,

the stress is proportional to the strain in the elastic limit.

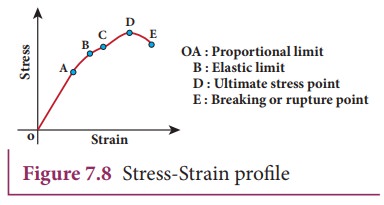

Stress ŌĆō Strain profile curve:

The

stress versus strain profile is a plot in which stress and strain are noted for

each load and a graph is drawn taking strain along the X-axis and stress along

the Y-axis. The elastic characteristics of the materials can be analyzed from

the stress-strain profile.

(a) Portion OA:

In

this region, stress is very small such that stress is proportional to strain,

which means HookeŌĆÖs law is valid. The point A is called limit of proportionality because

above this point HookeŌĆÖs law is not

valid. The slope of the line OA gives the YoungŌĆÖs modulus of the wire.

(b) Portion AB:

This

region is reached if the stress is increased by a very small amount. In this

region, stress is not proportional to the strain. But once the stretching force

is removed, the wire will regain its original length. This behaviour ends at

point B and hence, the point B is known as yield

point (elastic limit). The elastic behaviour of the material (here wire) in

stress-strain curve is OAB.

(c) Portion BC:

If

the wire is stretched beyond the point B (elastic limit), stress increases and

the wire will not regain its original length after the removal of stretching

force.

(d) Portion CD:

With

further increase in stress (beyond the point C), the strain increases rapidly

and reaches the point D. Beyond D, the strain increases even when the load is

removed and breaks (ruptures) at the point E. Therefore, the maximum stress

(here D) beyond which the wire breaks is called breaking stress or tensile

strength. The corresponding point D

is known as fracture point. The

region BCDE represents the plastic behaviour of the material of the wire.

Related Topics