Chapter: Modern Analytical Chemistry: Electrochemical Methods of Analysis

Voltammetric Techniques

Voltammetric Techniques

A number of voltammetric experiments are routinely

used in quantitative and qualitative analyses. Several of these methods are briefly described in this section.

Polarography

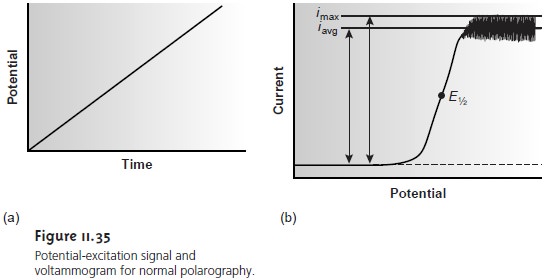

The earliest voltammetric experiment was normal polarography at a dropping mercury electrode. In normal polarography the potential is linearly scanned, producing voltammograms such as that shown in Figure 11.35. Although polarography takes place in an unstirred solution, a limiting current is obtained because the falling Hg drops mix the solution. Each new Hg drop, therefore, grows in a solution whose composition is identical to that of the initial bulk solution.

Oscillations in the current are due to the growth of the Hg drop, which leads to a time-dependent change in the area of the working electrode. The limiting current, which is also called

the diffusion current, may be measured from the maximum current, imax, or from the

average current, iavg. The

relationship between the

con- centration of analyte, CA, and

the limiting current

is given by the Ilikovic equation

(ilim)max = 706nD1/2m2/3t1/6CA

(ilim)avg = 607nD1/2m2/3t1/6CA

where

n is the number of electrons transferred in the redox reaction, D is

the analyte’s diffusion coefficient, m is the flow rate of the Hg, and t is the drop time. The half-wave potential, E1/2, provides

qualitative information about

the redox reaction (see Appendix 3E for a list of selected polarographic half-wave potentials).

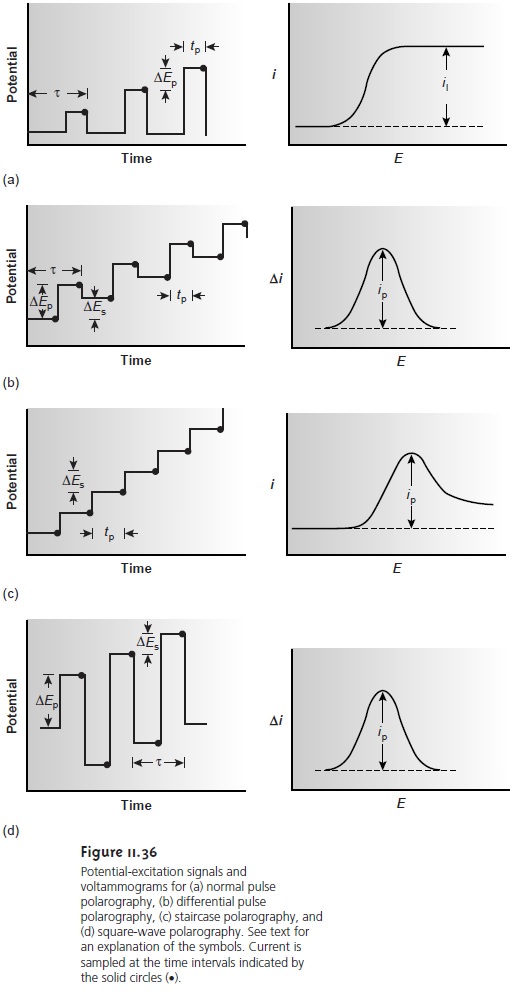

Normal polarography has been replaced by various forms of pulse polarogra- phy, several examples

of which are shown in Figure 11.36. Differential pulse po-

larography (Figure 11.36b),

for example, uses a series

of potential pulses

character- ized by a cycle of time τ, a pulse

time of tp, a potential pulse

of ∆Ep, and a potential

step per cycle of ∆Es. Typical

experimental conditions for differential pulse po-

larography are τ = 1 s, tp= 50 ms, ∆Ep = 50 mV, ∆Es = 2 mV. The current

is mea- sured twice,

for approximately 17 ms before

the forward pulse

and for approxi- mately 17 ms before

the reverse pulse.

The difference in the two currents gives

rise to a peak-shaped voltammogram. Other forms

of pulse polarography include nor- mal

pulse polarography (Figure 11.36a), staircase polarography (Figure 11.36c), and square-wave polarography (Figure 11.36d).

Limiting and peak currents are di-

rectly proportional to the concentration of analyte, and half-wave and peak poten- tials can be used for qualitative purposes. The popularity of pulse polarography is due to a substantial improvement in sensitivity and detection limits from those in

normal polarography.

|

3 3 |

Hydrodynamic Voltammetry

In

polarography a limiting

current is obtained

be- cause each falling

drop of mercury

returns the solution

near the electrode to its ini- tial composition. As noted

earlier, a limiting

current is also obtained whenever

the solution is stirred

during the analysis. The simplest means

of stirring the solution is with

a magnetic stir bar. More commonly, however,

stirring is achieved

by rotating the electrode.

In hydrodynamic voltammetry current is measured

as a function of the po-

tential applied to a solid

working electrode. The

same potential profiles used for polarography, such

as a linear scan or a differential pulse, are used

in hydrody- namic voltammetry. The resulting voltammograms are identical to those for po-

larography, except for the lack of current

oscillations resulting from the growth

of the mercury drops.

Because hydrodynamic voltammetry is not limited

to Hg elec- trodes, it is useful for the analysis

of analytes that are reduced

or oxidized at more

positive potentials.

Stripping Voltammetry

One of the most important quantitative voltammetric techniques is stripping voltammetry, which is composed of three related tech- niques: anodic, cathodic, and adsorptive stripping voltammetry. Since anodic stripping voltammetry has found the widest application, we consider it in the greatest detail.

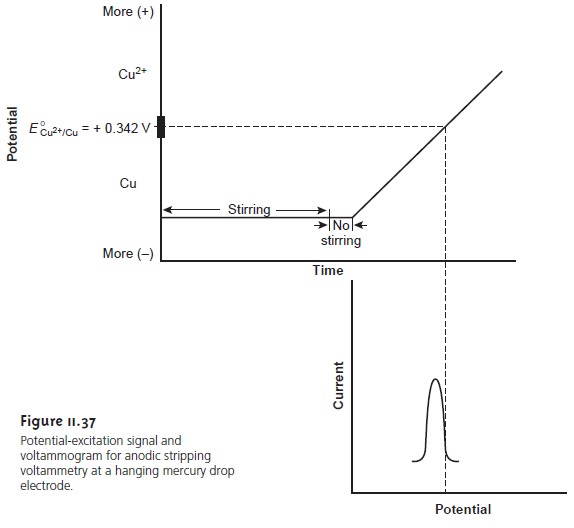

Anodic stripping voltammetry consists of two steps (Figure

11.37). The first

is a controlled potential electrolysis in which

the working electrode, usually a hanging mercury drop or mercury

film, is held at a cathodic potential sufficient to deposit the metal ion on the electrode. For example, with Cu2+ the deposition reaction is

Cu2+(aq)+ 2e– < = = = = > Cu(Hg)

where Cu(Hg) indicates that the copper

is amalgamated with

the mercury. This

step essentially serves as a means

of preconcentrating the analyte from the larger

volume of the solution

to the smaller volume of the electrode. The solution is stirred during electrolysis to increase the

rate of deposition. Near the end

of the deposition time stirring is stopped,

eliminating convection as a mode of mass transport. Deposition times of 1–30 min

are common, with

longer times being

used for analytes at lower

concentrations.

In the second

step, the potential is scanned anodically toward more positive potentials. When the potential of the working

electrode is sufficiently positive the analyte is stripped from

the electrode, returning to solution as its oxidized form

Cu(Hg) < = = = = > Cu2+(aq)+ 2e–

The current during

the stripping step is monitored as a function

of potential, giving rise to peak-shaped voltammograms similar to that

shown in Figure

11.37. The peak current

is proportional to the analyte’s concentration in the solution.

Anodic stripping voltammetry is very sensitive to experimental conditions, which must be carefully controlled if results

are to be accurate and

precise. Key vari- ables include the area

of the mercury

film electrode or the size

of the Hg drop when using a hanging mercury

drop electrode, the deposition time, the rest time, the rate

of stirring, and the scan rate during the stripping

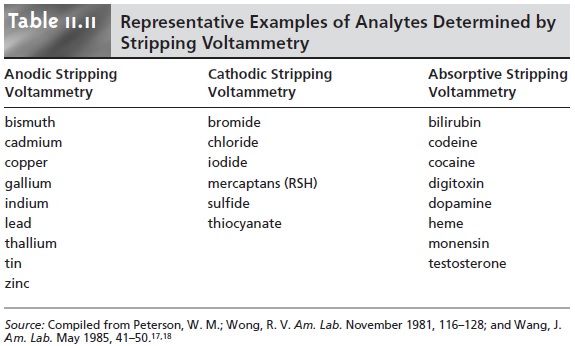

step. Anodic stripping

voltamme- try is best used for metals that form amalgams

with mercury, several

examples of which are listed in Table 11.11.

The experimental design for cathodic stripping voltammetry is similar to that for anodic stripping voltammetry with two exceptions.

|

2 |

First, the deposition step involves the oxidation of the Hg electrode to Hg 2+,

which then reacts

with the analyte to form an insoluble film at the surface of the electrode. For example, when Cl– is the analyte the deposition step is

2Hg(l) + 2Cl–(aq)

< = = = = > Hg2Cl2(s)+ 2e–

|

2 |

Hg2Cl2(s)+ 2e– < = = = = > 2Hg(l) + 2Cl–(aq)

Table 11.11 lists several analytes

that have been analyzed successfully by cathodic stripping voltammetry.

In adsorptive stripping voltammetry the deposition step occurs

without elec- trolysis. Instead, the analyte adsorbs

to the electrode’s surface. During deposition

the electrode is maintained at a potential

that enhances adsorption. For example,

adsorption of a neutral molecule

on a Hg drop is enhanced if the electrode is held at –0.4 V versus the

SCE, a potential at which the

surface charge of mercury is approx-

imately zero. When deposition is complete the potential is scanned in an anodic or

cathodic direction depending on whether we wish to oxidize or reduce the analyte.

Examples of compounds that have been analyzed by absorptive stripping voltam- metry also are listed

in Table 11.11.

Amperometry

The final

voltammetric technique to be considered is amperome- try, in which a constant potential

is applied to the working

electrode, and current

is measured as a function of time. Since

the potential is not scanned, amperometry does not lead to a voltammogram.

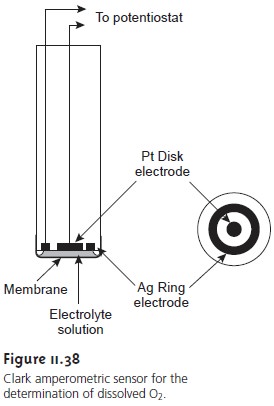

One important application of amperometry is in the construction

of chemical sensors. One of the first amperometric sensors to be developed was for dissolved O2 in blood, which

was developed in 1956 by L. C. Clark. The

design of the

amper- ometric sensor is shown in Figure 11.38

and is similar to potentiometric mem- brane electrodes. A gas-permeable membrane is stretched across

the end of the

sensor and is separated from the working

and counter electrodes by a thin solution

of KCl. The working electrode is a Pt disk cathode,

and an Ag ring anode

is the counter electrode.

Although several gases can diffuse across the membrane, including O2,

N2, and CO2, only oxygen is reduced at the cathode.

O2(aq)+ 4H3O+(aq)+ 4e– < =

= = = > 6H2O(l)

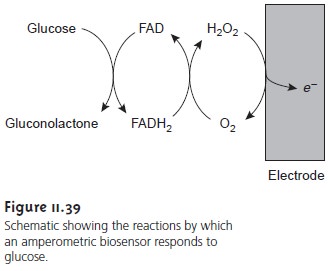

Another example of an amperometric sensor is the glucose sensor.

In this case the single membrane

in Figure 11.38 is replaced

with three membranes. The outermost membrane is of polycarbonate, which is permeable

to glucose and O2. The second membrane contains an immobilized preparation of glu- cose oxidase that catalyzes

the oxidation of glucose to gluconolactone and hy-

drogen peroxide.

β-D-glucose(aq)+ O2(g) + H2O(l)

< = = = = > gluconolactone(aq)+ H2O2(aq)

The hydrogen peroxide

then diffuses through

the innermost membrane

of cel- lulose acetate,

where it is oxidized at a Pt anode.

Figure 11.39 summarizes the reactions taking

place in this

amperometric sen- sor. FAD

is the oxidized form of flavin

adenine nucleotide (the

active site of the

enzyme glucose oxidase), and FADH2 is the active

site’s reduced form. Note that O2 serves

as a mediator, carrying electrons to the electrode. Other mediators, such as Fe(CN) 63–,

can be used in place

of O2.

By changing the

enzyme and mediator, the amperometric sen- sor in Figure 11.39 is easily extended to the analysis

of other sub- strates. Other bioselective materials may be incorporated into am- perometric sensors. For example, a CO2 sensor

has been developed using an amperometric O2 sensor with a two-layer membrane, one of which

contains an immobilized preparation of autotrophic bacteria. As CO2 diffuses through the membranes, it is converted to O2 by the bacteria, increasing the concentration of O2 at the Pt cathode

.

Related Topics