Chapter: Modern Analytical Chemistry: Electrochemical Methods of Analysis

Current in Voltammetry

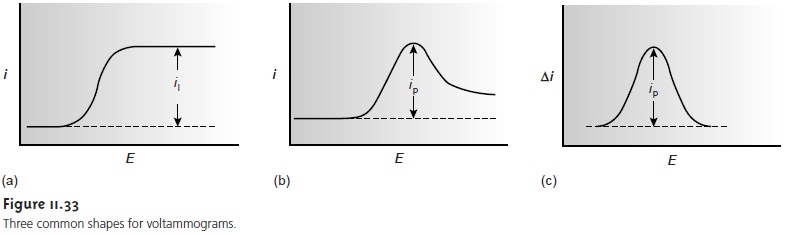

Current in Voltammetry

When

an analyte

is oxidized at the working

electrode, a current

passes electrons through

the external electric

circuitry to the auxiliary electrode, where reduc- tion of the

solvent or other components

of the solution matrix occurs. Reducing

an analyte at the

working electrode requires a source

of electrons, generating

a current that flows from the auxiliary

electrode to the cathode. In either case, a

current resulting from redox reactions at the working and auxiliary

electrodes is called

a faradaic current. In this section

we consider the factors

affecting the magnitude of this faradaic

current, as well as the

source of any nonfaradaic

currents.

Sign Conventions

Since the reaction of interest occurs

at the working

electrode, the classification of current is based on this reaction. A current due to the analyte’s

reduction is called a cathodic current

and, by convention, is considered positive. Anodic currents are

due to oxidation reactions and carry

a negative value.

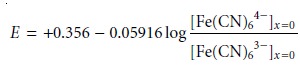

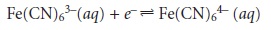

Influence of Applied Potential on the Faradaic Current

As an example, let’s

con- sider the faradaic

current when a solution of Fe(CN) 63– is reduced

to Fe(CN) 6

4– at

|

6 |

|

6 |

where +0.356 is the standard-state potential for the Fe(CN)63–/Fe(CN)64– redox couple, and

x

= 0 indicates that the concentrations of Fe(CN)63– and Fe(CN)64– are

those at the surface of the electrode. Surface concentrations are

used instead of bulk

concentrations since the equilibrium position

for the redox

reaction

can only be established electrochemically at the electrode’s

surface.

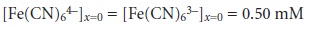

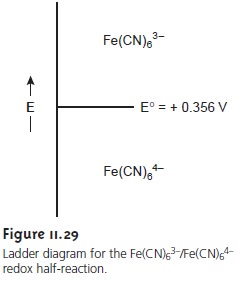

Let’s assume that we have a solution

for which the concentration of Fe(CN)63– is

1.0 mM and

in which Fe(CN) 64– is absent.

A ladder diagram

for this redox

example is shown

in Figure 11.29.

If a potential of +0.530

V is applied to the working

electrode, the concentrations of Fe(CN)63– and Fe(CN)64– at the surface of the elec- trode are unaffected, and no faradaic

current is observed. Switching the potential to +0.356 V, however,

requires that

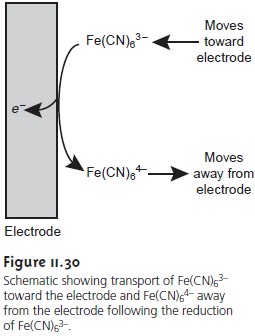

Which is only possible if a portion of the Fe(CN)63– at the electrode surface is re- duced to Fe(CN)64–. If this was all that occurred after the potential was applied, the result would be a brief surge of faradaic current that would quickly return to zero. However, although the concentration of Fe(CN)64– at the electrode surface is 0.50 mM, its concentration in the bulk of solution is zero. As a result, a concentration gradient exists between the solution at the electrode surface and the bulk solution. This concentration gradient creates a driving force that transports Fe(CN)64– away from the electrode surface (Figure 11.30). The subsequent decrease in the concen- tration of Fe(CN)64– at the electrode surface requires the further reductionof E

|

6 |

Although the applied

potential at the

working electrode determines if a faradaic current flows, the magnitude of the current

is determined by the rate of the result-

ing oxidation or reduction reaction

at the electrode surface. Two factors contribute to the rate of the electrochemical reaction: the rate

at which the

reactants and prod- ucts are transported to and from the surface

of the electrode, and the rate at which

electrons pass between

the electrode and

the reactants and

products in solution.

Influence of Mass Transport on the Faradaic Current

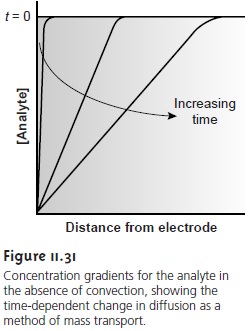

There are three modes of mass transport that influence the

rate at which

reactants and products are trans- ported to and from the electrode surface: diffusion, migration, and convection. Dif-

fusion from a region of high concentration to a region

of low concentration occurs

whenever the concentration of an ion or molecule at the surface

of the electrode is

different from that in bulk solution. When the potential applied to the working

electrode is sufficient to reduce

or oxidize the

analyte at the

electrode surface, a con-

centration gradient similar

to that shown

in Figure 11.31

is established. The

volume of solution in which the concentration gradient

exists is called

the diffusion layer. Without other modes of mass transport, the width of the diffusion

layer, δ, in- creases with time as the concentration of reactants near the electrode surface de- creases. The

contribution of diffusion to the rate

of mass transport, therefore, is

time-dependent.

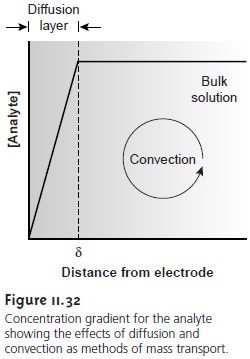

Convection occurs when a mechanical means is used to carry reactants toward the electrode and to remove products

from the electrode. The most common

means of convection is to stir the solution

using a stir bar. Other methods include

rotating the electrode and incorporating the electrode into a flow cell.

The final mode of mass transport is migration,

which occurs when charged

particles in solution are attracted or repelled from an electrode that has a positive or negative surface charge. Thus, when the electrode is positively charged,

negatively charged particles move toward the electrode, while

positively charged particles move toward the bulk solution. Unlike

diffusion and convection, migration only af- fects the mass transport of charged particles.

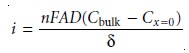

The flux of material to and from

the electrode surface

is a complex function of all

three modes of mass transport. In the limit

in which diffusion is the only

signifi- cant means for the mass transport of the reactants

and products, the current in a

voltammetric cell is given by

11.33

11.33

where n is the number

of electrons transferred in the redox reaction, F is Faraday’s constant, A is

the area of the electrode, D is the diffusion coefficient for the reactant

or product, Cbulk and Cx=0 are the concentration of the analyte

in bulk solution

and at the electrode surface, and δ is the

thickness of the

diffusion layer.

For equation 11.33

to be valid, convection and migration must not interfere with the formation of a diffusion layer between the electrode and the bulk of solu- tion. Migration is eliminated by adding a high concentration of an inert

supporting electrolyte to the analytical solution. Ions of similar

charge are equally

attracted or repelled from the surface

of the electrode and, therefore, have an equal probability

of undergoing migration. The large excess of inert ions, however, ensures

that few reactant and product ions will move as a result of migration. Although

convection may be easily

eliminated by not physically agitating the solution, in some situations it is desirable either

to stir the

solution or to push the

solution through an electro-

chemical flow cell. Fortunately, the dynamics of a fluid

moving past an electrode re- sults in a small

diffusion layer, typically of 0.001 – 0.01-cm thickness, in which the rate

of mass transport by convection drops

to zero (Figure

11.32).

Influence of the Kinetics of Electron Transfer on the Faradaic Current

The rate

of mass transport is one factor influencing the current in a voltammetric experiment. The ease with which electrons

are transferred between

the electrode and the reac- tants and products in solution also affects the current. When electron transfer

ki- netics are fast, the redox reaction is at equilibrium, and the concentrations of reac- tants and products at the electrode are those specified by the Nernst

equation. Such systems are considered electrochemically reversible. In other

systems, when electron transfer kinetics are sufficiently slow, the concentration of reactants and

products at the electrode surface, and thus the current,

differ from that predicted by the Nernst equation. In this case the system

is electrochemically irreversible.

Nonfaradaic Currents

Faradaic currents result from a redox

reaction at the elec-

trode surface. Other

currents may also exist in an electrochemical cell that are unre-

lated to any redox reaction.

These currents are called nonfaradaic currents

and must be accounted for if the

faradaic component of the measured current is to be

determined.

The most important example of a nonfaradaic current

occurs whenever the electrode’s potential is changed.

In discussing migration as a means

of mass trans- port, we noted that negatively charged

particles in solution

migrate toward a posi-

tively charged electrode, and positively charged particles move away from the same electrode. When an inert

electrolyte is responsible for migration, the result is a

structured electrode–surface interface called the electrical double

layer, or EDL, the

exact structure of which is of no concern in the context

of this text.

The movement of charged

particles in solution, however, gives rise to a short-lived, nonfaradaic charging current. Changing the potential of an electrode

causes a change in the structure of the EDL, producing a small charging

current.

Residual Current

Even in the absence of analyte, a small current

inevitably flows through an electrochemical cell.

This current, which

is called the residual

current, consists of two components: a faradaic current

due to the oxidation or reduction of trace

impurities, and the charging current.

Related Topics