Chapter: Modern Analytical Chemistry: Electrochemical Methods of Analysis

Controlled-Current Coulometry

Controlled-Current Coulometry

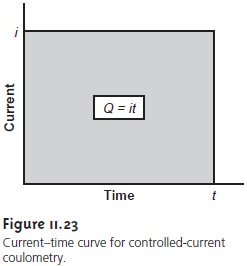

A second approach

to coulometry is to use a constant

current in place of a constant

potential (Figure 11.23).

Controlled-current coulometry, also

known as amperostatic coulometry or coulometric titrimetry, has two advantages over controlled-potential

coulometry. First, using

a constant current

makes for a more rapid

analysis since the current does not decrease

over time. Thus,

a typical analysis

time for controlled- current coulometry is less than 10 min, as opposed

to approximately 30–60 min for controlled-potential coulometry. Second, with a constant current

the total charge

is simply the product

of current and time (equation

11.24). A method for integrating the current–time curve, therefore, is not necessary.

Using a constant current does present two important experimental problems that must be solved

if accurate results

are to be obtained. First,

as electrolysis oc- curs the analyte’s concentration and, therefore, the current due to its oxidation

or reduction steadily decreases. To maintain a constant current

the cell potential must change until another

oxidation or reduction reaction can occur at the working

electrode. Unless the system is carefully designed, these secondary reac- tions will produce a current efficiency of less than 100%. The second problem

is the need for a method of determining when the analyte

has been exhaustively

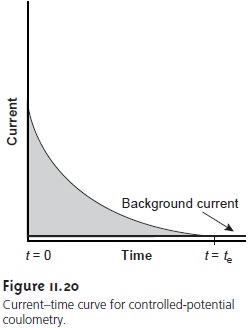

electrolyzed. In controlled-potential coulometry this is signaled by a decrease in the current to a constant

background or residual

current (see Figure

11.20). In controlled-current coulometry, however, a constant

current continues to flow even when the analyte has been completely oxidized or reduced. A suitable means of determining the

end-point of the

reaction, te, is needed.

Maintaining Current Efficiency

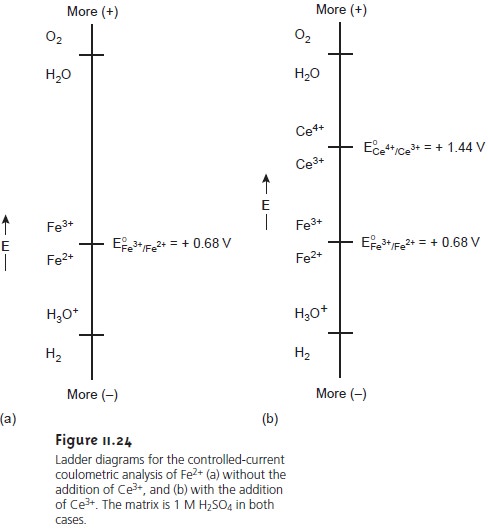

To illustrate why

changing the working electrode’s potential can lead to less than 100% current efficiency, let’s consider the coulomet-

ric analysis for Fe2+ based on its oxidation to Fe3+ at a Pt working

electrode in 1 M

H2SO4.

Fe2+(aq)

< = = = = > Fe3+(aq)+ e–

The ladder diagram

for this system

is shown in Figure 11.24a.

Initially the potential of the working electrode remains nearly constant

at a level near the standard-state

potential for the

Fe3+/Fe2+ redox couple. As the

concentration of Fe2+ decreases,

however, the potential of the working electrode

shifts toward more positive values until another oxidation reaction can provide the

necessary current. Thus,

in this case the potential eventually increases to a level

at which the

oxidation of H2O occurs.

6H2O(l) < = = = = > O2(g)+ 4H3O+(aq)+ 4e–

Since the current

due to the oxidation of H3O+ does not contribute to the oxidation of Fe2+, the current

efficiency of the analysis is less than 100%. To maintain a 100%

current efficiency the products of any competing oxidation reactions must react

both rapidly and quantitatively with the remaining Fe2+. This may be accomplished, for example, by adding

an excess of Ce3+ to

the analytical solution

(Figure 11.24b). When the potential of the working

electrode shifts to a more positive potential, the first species to be oxidized

is Ce3+.

Ce3+(aq)

< = = = = > Ce4+(aq)+ e–

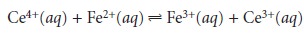

The Ce4+ produced at the working electrode rapidly mixes with the solution, where it reacts with any available Fe2+.

11.31

11.31

Combining these reactions gives the desired overall reaction of

Fe2+(aq)

< = = = = > Fe3+(aq)+ e–

In this manner,

a current efficiency of 100% is maintained. Furthermore, since the

concentration of Ce3+ remains at its initial

level, the potential of the working

elec- trode remains constant

as long as any Fe2+ is present.

This prevents other

oxidation reactions, such as that for H2O, from interfering with the analysis. A species, such as

Ce3+, which

is used to maintain 100% current efficiency, is called a mediator.

End Point Determination

Adding a mediator solves

the problem of maintaining

100% current efficiency, but does

not solve the

problem of determining when the analyte’s electrolysis is complete. Using

the same example, once all the

Fe2+ has been oxidized current continues to flow as a result

of the oxidation of Ce3+ and,

eventually, the oxidation of H2O. What is needed

is a means of indicating when the oxidation of Fe2+ is complete. In this respect it is convenient to treat a controlled-

current coulometric analysis as if electrolysis of the analyte

occurs only as a result

of its reaction with the mediator. A reaction between

an analyte and a mediator, such as that shown

in reaction 11.31,

is identical to that encountered in a redox

titration. Thus, the same end points

that are used in redox

titrimetry, such as visual indicators, and potentiometric and conductometric measurements, may be used to signal the

end point of a controlled-current coulometric analysis. For exam- ple, ferroin may be used to provide a visual end point for the Ce3+-mediated coulo- metric analysis for Fe2+.

Instrumentation

Controlled-current coulometry normally is carried

out using a galvanostat and an electrochemical cell consisting of a working

electrode and a counterelectrode. The working electrode, which often is constructed from Pt, is also

called the generator electrode since

it is where the mediator

reacts to generate

the species reacting with the analyte.

The counterelectrode is isolated from the analyti- cal solution by a salt bridge

or porous frit

to prevent its

electrolysis products from reacting with the analyte.

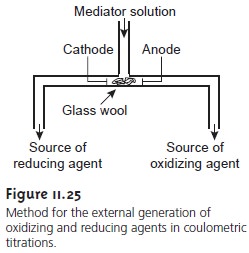

Alternatively, oxidizing or reducing the mediator can be

carried out externally, and the

appropriate products flushed

into the analytical solu- tion. Figure 11.25 shows one simple method by which oxidizing and reducing agents can be generated

externally. A solution

containing the mediator

flows under the influence of gravity into a small-volume electrochemical cell. The products gen- erated at the anode

and cathode pass through separate

tubes, and the appropriate

oxidizing or reducing reagent can be selectively delivered to the analytical solution.

For example, external generation of Ce4+ can be obtained using

an aqueous solution of Ce3+ and the

products generated at the anode.

The other necessary instrumental component for controlled-current coulometry is an accurate clock for measuring

the electrolysis time, te, and a switch for starting and stopping the electrolysis. Analog clocks can read time to the nearest ±0.01

s, but the need

to frequently stop

and start the

electrolysis near the

end point leads

to a net uncertainty of ±0.1 s. Digital clocks provide a more accurate

measurement of time, with errors of ±1 ms being

possible. The switch

must control the flow of current and the

clock, so that an accurate

determination of the electrolysis time is possible.

Coulometric Titrations

Controlled-current coulometric methods commonly are called coulometric titrations because of their

similarity to conventional titrations. We already have noted, in discussing the

controlled-current coulometric determi-

nation of Fe2+, that the oxidation of Fe2+ by Ce4+ is identical to the reaction

used in a redox

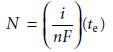

titration. Other similarities between the two techniques also exist. Combining equations 11.23 and 11.24 and solving for the moles

of analyte gives

11.32

11.32

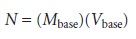

Compare this equation with the relationship between the moles of

strong acid, N, titrated with a

strong base of known concentration.

The titrant in a conventional titration is replaced

in a coulometric titration by a

constant-current source whose current is analogous to the titrant’s

molarity. The time needed

for an exhaustive electrolysis takes the

place of the

volume of titrant, and the switch for

starting and stopping the electrolysis serves

the same function as a buret’s stopcock.

Related Topics