Chapter: Modern Analytical Chemistry: Electrochemical Methods of Analysis

Voltammetric Measurements

Voltammetric Measurements

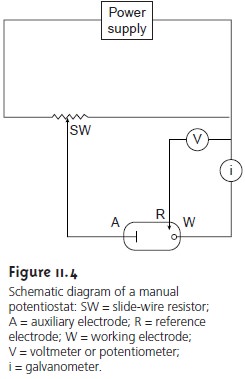

Although early voltammetric methods relied on the use of only two

electrodes, modern voltammetry makes use of a three-electrode po-tentiostat, such as that shown

in Figure 11.4.

A time-dependent po- tential excitation signal is applied to the working

electrode, chang- ing its potential

relative to the fixed potential of the reference

electrode. The resulting

current between the working and auxiliary

electrodes is measured. The auxiliary electrode is generally a plat- inum wire,

and the SCE

and Ag/AgCl electrode are common refer- ence electrodes.

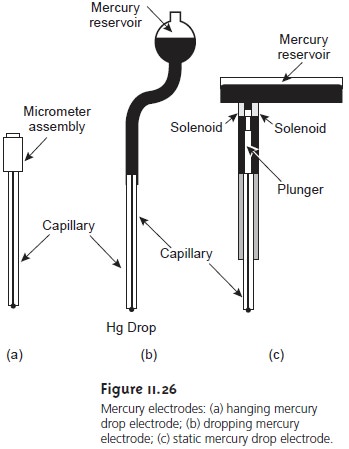

Several

different materials have been used as working elec-

trodes, including mercury,

platinum, gold, silver,

and carbon. The earliest voltammetric techniques, including

polarography, used mercury for the working electrode. Since

mercury is a liquid, the working electrode often consists of a

drop suspended from

the end of a capillary tube (Figure 11.26).

In the hanging

mercury drop electrode, or HMDE,

a drop of the desired

size is formed

by the ac- tion of a micrometer screw

that pushes the

mercury through a narrow capillary tube. In the dropping mercury

electrode, or DME,

mercury drops form

at the end of

the capillary tube

as a result of gravity. Unlike the HMDE,

the mercury drop

of a DME grows

continuously and has

a finite lifetime of several seconds. At the end of

its lifetime the mercury drop is dislodged, either manually or by gravity,

and replaced by a new drop. The static mercury drop electrode,

or SMDE, uses a

solenoid-driven plunger to control the

flow of mercury. The SMDE can

be used as either a hanging mercury

drop electrode or as a dropping mercury

electrode. A single activation of the solenoid

momentarily lifts the plunger, allowing

enough mercury to flow

through the capillary to form a single drop.

To obtain a dropping mercury

elec- trode the solenoid

is activated repeatedly. A mercury film electrode consists

of a thin layer of mercury

deposited on the surface of a solid

carbon, platinum, or gold elec- trode. The solid electrode is placed in a solution

of Hg2+

and held at a potential at which the reduction of Hg2+ to Hg is favorable, forming a thin

mercury film.

Mercury has several

advantages as a working electrode. Perhaps its most im-

portant advantage is its high

overpotential for the

reduction of H3O+

to H2, which allows for the application of potentials as negative as 1 V versus the SCE in acidic

solutions, and –2 V versus

the SCE in basic solutions. A species such

as Zn2+, which is difficult to reduce at other electrodes without simultaneously reducing

H3O+, is easily reduced

at a mercury working electrode. Other advantages include

the ability of metals

to dissolve in the mercury, resulting in the

formation of an amalgam,

and the ability to easily renew the surface

of the electrode by extruding

a new drop. One limitation to its use as a working electrode is the ease with which

Hg is oxidized. For this reason,

mercury electrodes cannot

be used as at potentials more positive than –0.3 V to +0.4 V versus

the SCE, depending on the composition of the solution.

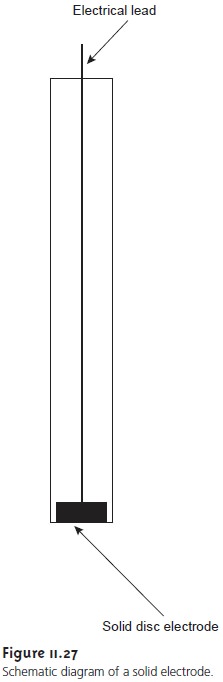

Solid electrodes constructed using platinum, gold,

silver, or carbon

may be used over a range of potentials, including potentials that are negative

and positive with respect

to the SCE. For example,

the potential range

for a Pt electrode extends from approximately +1.2 V to –0.2

V versus the

SCE in acidic

solutions and from +0.7 V to 1 V versus the SCE in basic solutions. Solid electrodes, therefore, can be used in place of mercury for many voltammetric analyses requiring negative

po- tentials and for voltammetric analyses

at positive potentials at which mercury

elec- trodes cannot be used. Except

for the carbon

paste electrode, solid

electrodes are fashioned into

disks that are

sealed into the

end of an inert support

and are in con-

tact with an electrical lead

(Figure 11.27). The

carbon paste electrode is made by filling the cavity at the end of the inert support

with a paste consisting of carbon

particles and a viscous oil. Solid electrodes are not without

problems, the most im-

portant of which is the

ease with which

the electrode’s surface

may be altered

by the adsorption of solution species

or the formation of oxide

layers. For this reason

solid electrodes need

frequent reconditioning, either

by applying an appropriate

potential or by polishing.

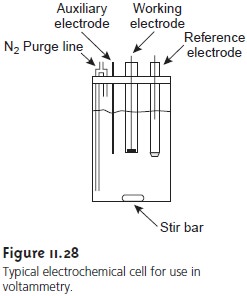

A typical arrangement for a voltammetric electrochemical cell is shown in Figure 11.28. Besides the working,

reference, and auxiliary

electrodes, the cell also in- cludes a N2 purge

line for removing

dissolved O2 and an optional

stir bar. Electro- chemical cells are available in a variety

of sizes, allowing

for the analysis

of solution volumes ranging

from more than 100 mL to as small as 50 μL.

Related Topics