Chapter: Modern Analytical Chemistry: Electrochemical Methods of Analysis

Controlled-Potential Coulometry

Controlled-Potential Coulometry

The easiest method

for ensuring 100% current efficiency is to maintain

the working electrode at a constant

potential that allows

for the analyte’s quantitative oxidation

or reduction, without simultaneously oxidizing or reducing an interfering species. The current flowing through an

electrochemical cell under a constant potential is proportional to the analyte’s concentration. As electrolysis progresses the analyte’s

concentration decreases, as does the

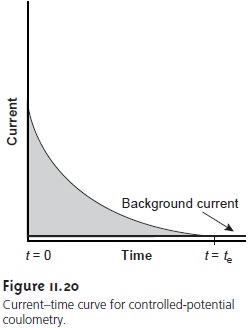

current. The resulting current-versus-time pro-

file

for controlled-potential coulometry, which also is known as potentiostatic

coulometry, is shown in Figure 11.20. Integrating the area under the curve (equa-

tion 11.25), from t = 0 until t =

te, gives

the total charge.

In this section

we consider the experimental parameters and instrumentation needed to develop

a controlled- potential coulometric method of analysis.

Selecting a Constant Potential

In controlled-potential coulometry, the potential is selected so that the desired oxidation

or reduction reaction

goes to completion without interference from redox reactions involving other components of the sam- ple

matrix. To see how an appropriate potential

for the working electrode is se-

lected, let’s develop a constant-potential coulometric method for Cu2+ based on its reduction to copper metal

at a Pt cathode working

electrode.

Cu2+(aq)+ 2e– < = = = = > Cu(s)

………………….. 11.26

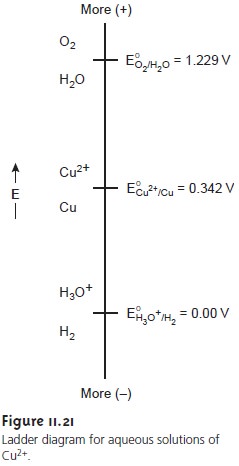

A ladder diagram

for a solution of Cu2+ (Figure 11.21)

provides a useful

means for evaluating the

solution’s redox properties. From the ladder

diagram we can

see that reaction 11.26 is

favored when the working electrode’s potential is more negative than +0.342

V versus the SHE (+0.093

V versus the SCE). To maintain a 100% cur- rent efficiency, however, the

potential must be selected so that the

reduction of H3O+ to H2 does not contribute significantly to the total

charge passed at the electrode.

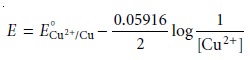

The potential needed

for a quantitative reduction of Cu2+ can be calculated using the Nernst equation

11.27

11.27

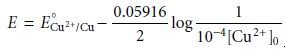

where [Cu2+]0

is the initial concentration of Cu2+ in the sample. Substituting equa- tion 11.28

into equation 11.27 gives the desired potential electrode as

If the initial

concentration of Cu2+ is 1.00

x 10–4

M, for example, then the cathode’s potential must be more negative than +0.105 V versus the SHE (–0.139

V versus the SCE)

to achieve a quantitative reduction of Cu2+ to Cu. Note that

at this potential H3O+ is not reduced to H2, maintaining a 100% current

efficiency. Many of the

published procedures for the controlled-potential coulometric analysis of Cu2+ call

for potentials that are more negative than that shown

for the reduction of H3O+ in Figure 11.21.12 Such potentials can be used,

however, because the

slow kinetics for reducing H3O+ results in a significant overpotential that shifts the potential of the H3O+/H2 redox

couple to more

negative potentials.

Minimizing Electrolysis Time

The current-time curve for controlled-potential coulometry in

Figure 11.20 shows that the current decreases continuously

throughout electrolysis. An exhaustive electrolysis, therefore, may

require a long time. Since time is an important consideration in choosing and designing analyt- ical methods, the factors

that determine the analysis time need to be considered.

The change in current as a function

of time in controlled-potential coulometry is approximated by an exponential decay;

thus, the current

at time t is

i =

i0e–kt

………………….. 11.29

where i0 is the initial

current, and k is

a constant that is directly

proportional to the area

of the working electrode and the rate of stirring

and inversely proportional to the volume of the solution. For an exhaustive electrolysis in which

99.99% of the analyte is oxidized or reduced, the

current at the

end of the

analysis, te, may be ap- proximated as

i (10–4)i0 ………………….. 11.30

Substituting equation 11.30

into equation 11.29

and solving for te gives the mini- mum time for an exhaustive electrolysis as

From this equation we see that

increasing k leads to a shorter

analysis time. For

this reason controlled-potential coulometry is carried out

in small-volume electrochem- ical cells, using electrodes with large surface

areas and with high stirring

rates. A quantitative electrolysis typically requires approximately 30–60 min, although

shorter or longer

times are possible.

Instrumentation

The potential in controlled-potential coulometry is set using

a three-electrode potentiostat. Two types of working electrodes are commonly

used: a Pt electrode manufactured from platinum-gauze and

fashioned into a cylindrical tube, and an Hg pool electrode. The large overpotential for reducing H3O+ at

mercury makes it the electrode of choice for

analytes requiring negative potentials. For

example, potentials more

negative than –1 V versus

the SCE are feasible at an Hg electrode (but not at a Pt electrode), even in very acidic solu- tions. The ease with which mercury

is oxidized, however,

prevents its use at po- tentials that are positive

with respect to the SHE. Platinum working

electrodes are used when positive potentials are required. The auxiliary electrode, which is often a Pt wire,

is separated by a salt

bridge from the

solution containing the

an- alyte. This is necessary to prevent electrolysis products generated at the auxiliary electrode from

reacting with the

analyte and interfering in the analysis. A satu- rated calomel

or Ag/AgCl electrode serves as the reference electrode.

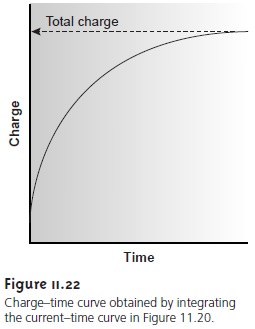

The other essential feature of instrumentation for controlled-potential coulom- etry is a means

of determining the total charge

passed during electrolysis. One method is to monitor

the current as a function

of time and determine the area

under the curve (see Figure 11.20). Modern instruments, however, use electronic

integration to monitor

charge as a function of time. The

total charge at the end

of the electrolysis then can be read directly from a digital readout or

from a plot of charge versus time (Figure

11.22).

Related Topics