Chapter: Modern Analytical Chemistry: Chromatographic and Electrophoretic Methods

Optimizing Chromatographic Separations Using Column Efficiency to Optimize Resolution

Using Column Efficiency to Optimize Resolution

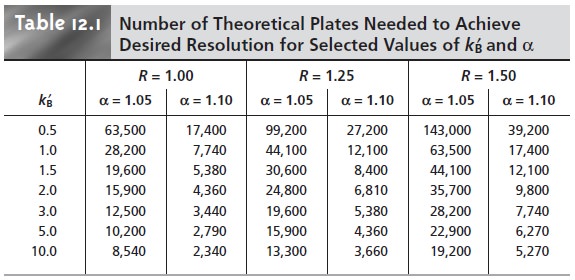

If the capacity factor and α are known, then equation 12.21 can be used to calculate the number of theoretical plates needed to achieve a desired resolution (Table 12.1). For example, given α = 1.05 and kB’ = 2.0, a resolution of 1.25 requires approxi- mately 24,800 theoretical plates. If the column only provides 12,400 plates, half of what is needed, then the separation is not possible. How can the number of theoret- ical plates be doubled? The easiest way is to double the length of the column; how- ever, this also requires a doubling of the analysis time. A more desirable approach is to cut the height of a theoretical plate in half, providing the desired resolution with- out changing the analysis time. Even better, if H can be decreased by more than 50%, it also may be possible to achieve the desired resolution with an even shorter analysis time by decreasing kB’ or α.

To determine how the height

of a theoretical plate can be decreased, it is neces- sary to understand the

experimental factors contributing to the broadening of a solute’s chromatographic band. Several theoretical treatments of band broadening

have been proposed. We will consider one approach in which the height of a theo- retical plate is determined by four contributions: multiple paths, longitudinal diffu- sion, mass transfer

in the stationary phase, and mass transfer

in the mobile phase.

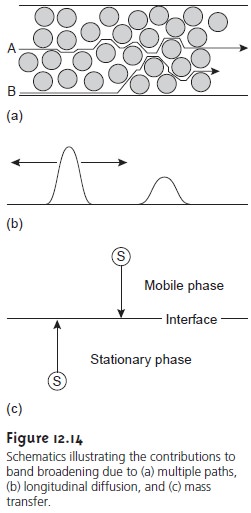

Multiple Paths

Solute

molecules passing through a chromatographic column

travel separate paths

that may differ

in length. Because

of these differences in path length, solute

molecules injected simultaneously elute at different times. The princi- pal factor contributing to this variation in path length

is a nonhomogeneous pack-

ing of the stationary phase

in the column. Differences in particle size and packing consistency cause solute molecules

to travel paths of different

length. Some solute molecules follow relatively straight

paths through the column, but others follow

a longer, more tortuous path (Figure 12.14a). The contribution of

multiple paths to the height

of a theoretical plate, Hp, is

Hp = 2λdp………………12.23

where dp is

the average diameter of the particulate packing material, and λ is a con-stant accounting for the consistency of the packing.

A smaller range

of particle sizes and a more consistent packing produce a smaller value

for λ. Note that for an open tubular column, which does

not contain packing

material, Hp is 0.

Longitudinal Diffusion

The

second contribution to band broadening is the result of the solute’s longitudinal diffusion in the mobile

phase. Even if the mobile

phase velocity is 0, solute molecules

are constantly in motion, diffusing

through the mo- bile

phase. Since the concentration of solute is greatest at the center of a chromato-

graphic band, more solute diffuses

toward the band’s

forward and rear edges than diffuses toward the band’s center. The net result is an increase in the band’s width

(Figure 12.14b). The contribution of longitudinal diffusion to the height

of a theo- retical plate, Hd, is

where Dm is the solute’s diffusion coefficient in the mobile

phase, u is the

mobile phase velocity, and Îł is a constant related to the

column packing. The

effect of Hd

on the height of a theoretical plate

is minimized by a high

mobile-phase velocity.

Because a solute’s diffusion coefficient is larger in a gaseous

mobile phase than in

a liquid mobile phase, longitudinal diffusion is a more serious

problem in gas chromatography.

Mass Transfer

The final two contributions to band broadening result from the fi-

nite time required for a solute molecule

to diffuse through

the stationary phase and

mobile phase. A chromatographic separation occurs because solutes

move between the stationary and mobile phases.

For a solute to move from one phase to the other, it

must first diffuse

to the interface between the two phases

(Figure 12.14c)—a process

called mass transfer. A

contribution to band broadening occurs

whenever the solute’s movement

to the interface is not fast enough

to maintain a true equilib- rium distribution of solute

between the two phases. Thus,

solute molecules in the

mobile phase move farther down the column

than expected before

passing into the stationary phase. Solute molecules in the stationary phase, on the other hand,

take longer than expected

to cross into the mobile

phase. The contributions of mass transfer in the stationary phase, Hs, and mass transfer

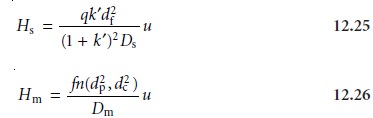

in the mobile phase, Hm, are given by

where df is the thickness of the stationary phase, dc is the column’s

diameter, Ds is the solute’s diffusion coefficient in the

stationary phase, q is

a constant related

to the column packing

material, and the remaining terms

are as previously defined. As in-

dicated in equation 12.26, the

exact form of Hm is unknown, although it is a func-

tion of particle size and column diameter.

The contribution of mass transfer

to the height of a theoretical plate is smallest

for slow mobile-phase velocities, smaller di- ameter packing materials, and

thinner films of stationary phase.

Putting It All Together

The net height

of a theoretical plate is a summation of the

contributions from each of the terms in equations 12.23–12.26; thus,

H =

Hp+

Hd + Hs + Hm………………12.27

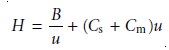

An alternative form of this equation is the van Deemter equation

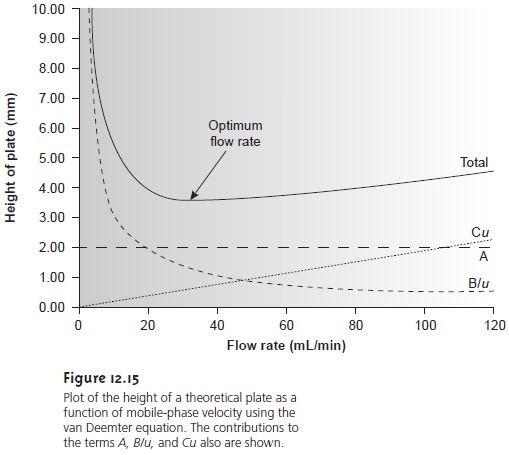

which emphasizes the importance of the mobile phase’s flow rate. In the van Deemter equation, A accounts for multiple paths (Hp), B/u for longitudinal diffusion (Hd), and Cu for the solute’s mass transfer in the stationary and mobile phases (Hs and Hm).

There is some disagreement on the correct

equation for describing the relation- ship between

plate height and mobile-phase velocity.

In addition to the van Deemter equation

(equation 12.28), another

equation is that proposed by Hawkes

where Cs and Cm are the mass transfer terms

for the stationary and mobile phases respectively. A third equation

was devised by Knox.

All three equations, and others, have been used to characterize

chromatographic systems, with no single equation

providing the best explanation in every case.

To increase the number of theoretical plates

without increasing the length of the

column, it is necessary to decrease one or more of the terms in equation 12.27 or

equation 12.28. The easiest way to accomplish this is by adjusting the velocity of the

mobile phase. At a low mobile-phase velocity, column efficiency is limited by longitudinal diffusion, whereas at

higher velocities efficiency is limited by the

two mass transfer terms.

As shown in Figure 12.15

(which is interpreted in terms of equation 12.28), the optimum

mobile-phase velocity corresponds to a minimum

in a plot of H as a function of u.

The remaining parameters affecting the height

of a theoretical plate are deter-

mined by the construction of the column

and suggest how the column’s

design may be used

to improve efficiency. For example, both

Hp and

Hm are

a function of the

size of the particles used for the packing material.

Decreasing particle size, therefore, is one approach

to improving efficiency. A decrease in particle size is

limited, however, by the need for a greater pressure to push the mobile phase through

the column.

One of the most important advances in column construction has been the de- velopment of open tubular, or capillary columns that contain no packing material (dp = 0). Instead, the interior wall of a capillary column is coated with a thin film of the stationary phase. The absence of packing material means that the mobile phase can move through the column with substantially less pressure.

As a result,

capillary columns can be manufactured with

much greater lengths

than is possible with a packed column.

Furthermore, plate height is reduced

because the Hp term in equation 12.27 disappears and the Hm term

becomes smaller. The combination of a

smaller height for a theoretical plate and a longer column leads to an approximate 100-fold increase

in the number of theoretical plates. Capillary columns

are not without disadvantages. Because capillary columns

are much narrower than packed

columns, they require a significantly smaller amount of sample. Difficulties with re- producibly injecting small samples complicates the use of capillary chromatography for quantitative work.

Another approach to improving resolution is to use thin films

of stationary phase. Capillary columns used in gas chromatography and the bonded

phases com- monly used in HPLC provide a significant decrease

in plate height due to the reduc- tion of the Hs term in equation

12.27.

Related Topics