Chapter: Modern Analytical Chemistry: Chromatographic and Electrophoretic Methods

Gas Chromatography: Quantitative Applications

Quantitative Applications

Gas chromatography is widely used for the analysis of a diverse

array of samples

in environmental, clinical, pharmaceutical, biochemical, forensic, food

science, and petrochemical laboratories. Examples

of these applications are discussed in the fol- lowing sections.

Environmental Analysis

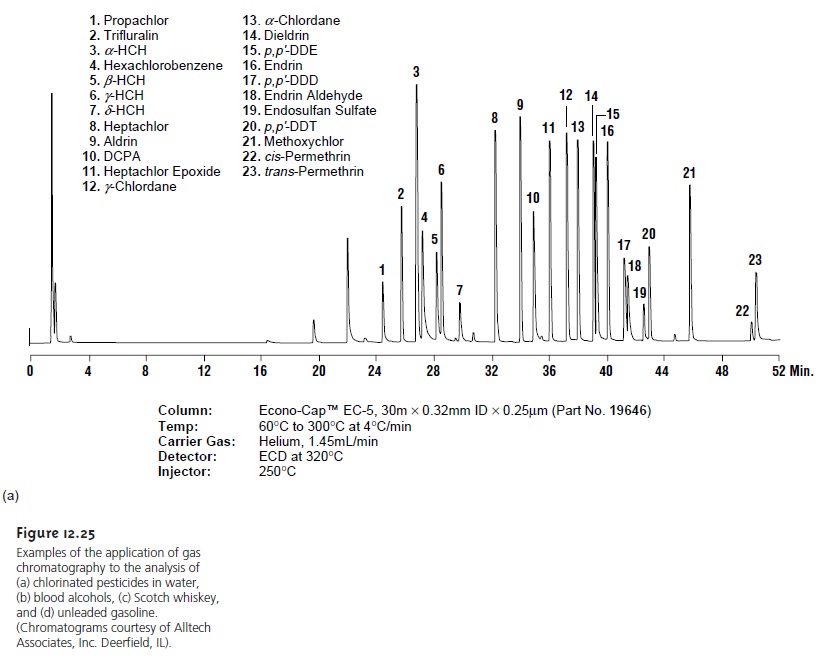

One of the most important environmental applications of gas chromatography is for the analysis of numerous organic pollutants in air, water, and wastewater. The analysis of volatile organics in drinking water, for example, is accomplished by a purge and trap, followed by their separation on a capillary col- umn with a nonpolar stationary phase. A flame ionization, electron capture, or mass spectrometer can be used as a detector. Figure 12.25a shows a typical chro- matogram for the analysis of chlorinated pesticides in water.

Clinical Analysis

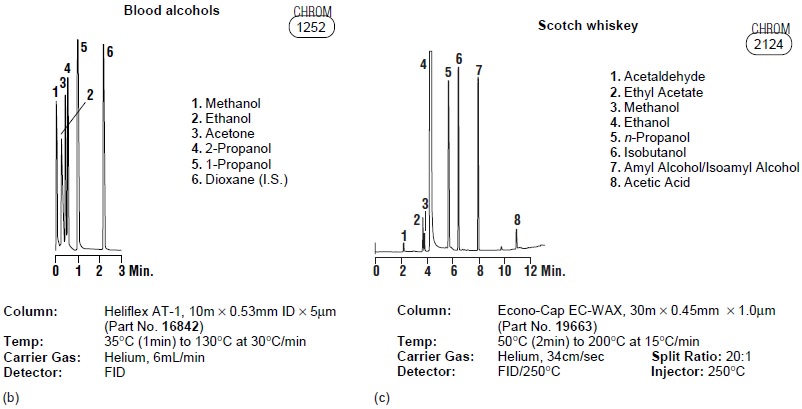

Clinical, pharmaceutical, and forensic labs make frequent

use of gas chromatography for the analysis

of drugs. Because

the sample’s matrix

is often incompatible with

the GC column, analytes generally must be isolated by extrac- tion. Figure

12.25b shows how gas chromatography can be used in monitoring blood alcohol levels.

Consumer Goods

Many flavors, spices,

and fragrances are

readily analyzed by GC,

using headspace analysis or thermal desorption. Foods and beverages are analyzed

either directly or following a suitable extraction. Volatile materials, such as those found in spices and fragrances, often can be obtained by headspace sampling.

Fig- ure 12.25c shows

a typical analysis of a sample

of Scotch whiskey.

Petroleum Industry

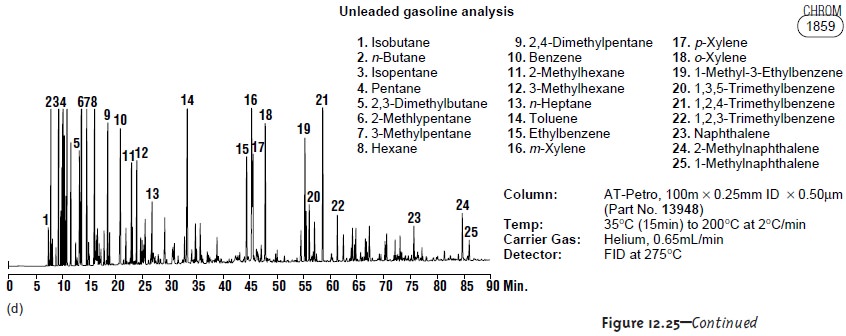

Gas chromatography is ideally suited for the analysis of petro-

leum products, including gasoline, diesel fuel, and oil. A typical chromatogram for the analysis of unleaded gasoline

is shown in Figure 12.25d.

Quantitative Calculations

In a quantitative analysis, the height or area of an ana- lyte’s chromatographic peak is used to determine its concentration. Although peak height is easy to measure, its utility is limited by the inverse relationship between the height and width of a chromatographic peak.

Unless chromatographic conditions are carefully controlled to maintain a constant column efficiency, variations in peak height may decrease the accuracy and precision of the quantitative analysis. A better choice

is to measure the area under the chromatographic peak with an inte-

grating recorder. Since

peak area is directly proportional to the amount

of analyte that was injected, changes

in column efficiency will not affect

the accuracy or preci-

sion of the analysis.

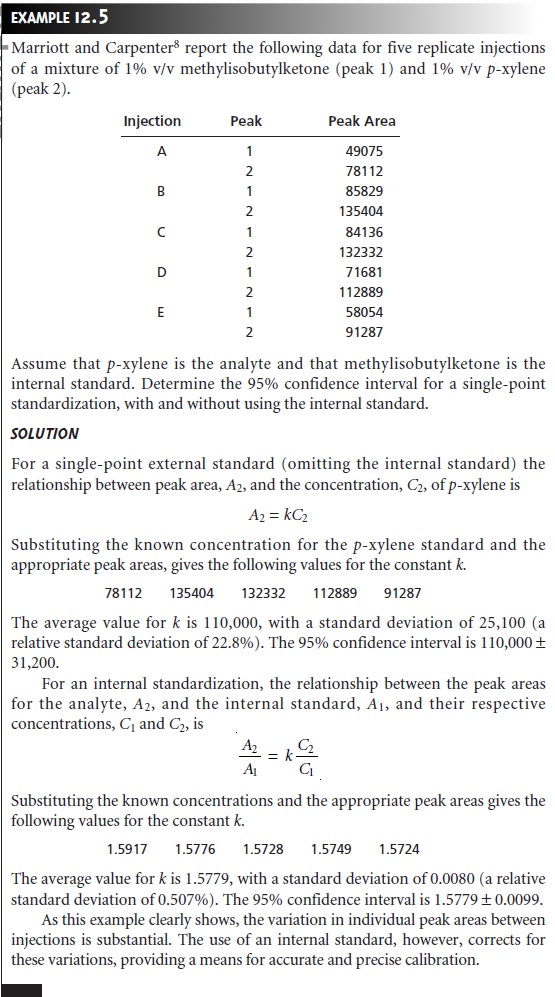

Calibration curves are usually constructed by analyzing a series of external

standards and plotting the detector’s signal

as a function of their

known concentra- tions. As long as the injection volume is identical for every standard

and sample, calibration curves prepared in this fashion

give both accurate

and precise results. Unfortunately, even under the best of conditions, replicate

injections may have vol-

umes that differ by as much as 5% and often may be substantially worse. For this reason, quantitative work requiring

high accuracy and precision is accomplished using an internal standard.

Related Topics