Chapter: Modern Analytical Chemistry: Chromatographic and Electrophoretic Methods

Gas Chromatography: Chromatographic Columns

Chromatographic Columns

A chromatographic column provides a location for physically retaining

the station- ary phase.

The column’s construction also influences the

amount of sample

that can be handled, the efficiency of the separation, the number of analytes that

can be eas- ily separated, and the amount of time required

for the separation. Both packed and capillary columns are used

in gas chromatography.

Packed Columns

A packed column is constructed from glass, stainless steel,

copper or aluminum

and is typically 2–6 m in length,

with an internal

diameter of 2–4 mm. The column

is filled with a particulate solid support, with particle diam- eters ranging from 37–44 μm to 250–354 μm.

The most widely

used particulate support

is diatomaceous earth,

which is com- posed of the silica skeletons of diatoms. These particles are quite porous,

with sur- face areas

of 0.5–7.5 m2/g,

which provides ample

contact between the mobile phase and stationary phase. When hydrolyzed, the surface of a diatomaceous earth con- tains silanol

groups (–SiOH), providing

active sites that absorb solute molecules in gas–solid chromatography.

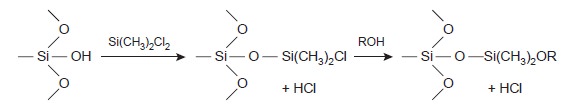

In gas–liquid

chromatography (GLC), separation is based on the partitioning of solutes between a gaseous mobile

phase and a liquid stationary phase coated on the

solid packing material.

To avoid the adsorption of solute molecules

on exposed packing material, which degrades the quality of the separation, surface silanols are deactivated by silanizing with dimethyldichlorosilane and washing with an alcohol (typically methanol) before coating

with stationary phase.

More recently, solid

supports made from

glass beads or fluorocarbon polymers have been introduced. These

supports have the

advantage of being

more inert than

di- atomaceous earth.

To minimize the multiple path and mass transfer contributions to plate height (equations 12.23 and 12.26),

the packing material

should be of as small a diameter as is practical and loaded with a thin film of stationary phase

(equation 12.25). Compared with capillary columns,

which are discussed

in the next section, packed columns can handle larger

amounts of sample.

Samples of 0.1–10

ÎĽL are routinely analyzed with a packed column.

Column efficiencies are typically several

hundred to 2000 plates/m, providing columns with

3000–10,000 theoretical plates.

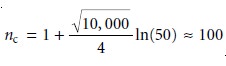

Assuming Vmax/Vmin is approximately 50, a packed

column with 10,000

theoretical plates has a

peak capacity (equation 12.18) of

Capillary Columns

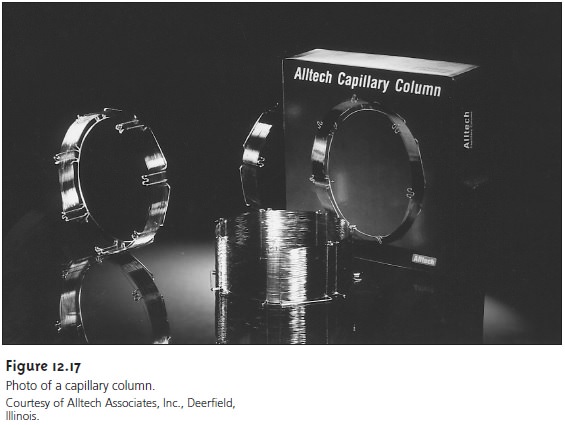

Capillary, or open tubular columns are constructed from fused silica coated

with a protective polymer. Columns

may be up to 100 m in length with an internal

diameter of approximately 150–300 μm (Figure

12.17). Larger bore columns

of 530 ÎĽm, called megabore

columns, also are available.

Capillary columns are of

two principal

types. Wall-coated open tubular columns (WCOT) contain a thin layer of stationary phase,

typically 0.25 ÎĽm thick,

coated on the capillary’s inner wall. In support-coated open tubular columns

(SCOT), a thin layer of a solid

support, such as a diatomaceous earth, coated with a

liquid stationary phase

is attached to the capillary’s inner wall.

Capillary columns provide

a significant improvement in separation efficiency. The pressure needed to move the mobile phase through a packed column limits its length. The absence of packing material

allows a capillary

column to be longer than a

packed column. Although

most capillary columns

contain more theoretical plates per meter than a packed

column, the more important contribution to their greater efficiency is the ability

to fashion longer

columns. For example, a 50-m capillary column with 3000 plates/m

has 150,000 theoretical plates and, assuming

Vmax/Vmin is approximately 50,3 a peak

capacity of almost

380. On the

other hand, packed columns can handle larger samples. Due to its smaller diameter,

capillary columns require smaller

samples; typically less

than 10–2 μL.

Related Topics