Chapter: Modern Analytical Chemistry: Spectroscopic Methods of Analysis

Quantitative Applications - Atomic Absorption Spectroscopy

Quantitative Applications

Atomic absorption using either flame or electrothermal atomization is widely used

for the analysis of trace

metals in a variety of sample matrices. Using the atomic

ab- sorption analysis for

zinc as an example, procedures have been developed for its de- termination in samples as diverse as water and

wastewater, air, blood,

urine, muscle tissue, hair,

milk, breakfast cereals, shampoos, alloys, industrial plating baths, gaso-

line, oil, sediments, and rocks.

Developing a quantitative atomic absorption method

requires several consider- ations, including choosing a method of atomization, selecting

the wavelength and slit

width, preparing the sample for analysis, minimizing spectral and chemical

in- terferences, and selecting a method of standardization. Each of these

topics is con- sidered in this section.

Flame Versus Electrothermal Atomization

The

choice of atomization method is determined primarily by the analyte’s concentration in the samples being

analyzed. Because of its greater sensitivity, detection limits for most elements

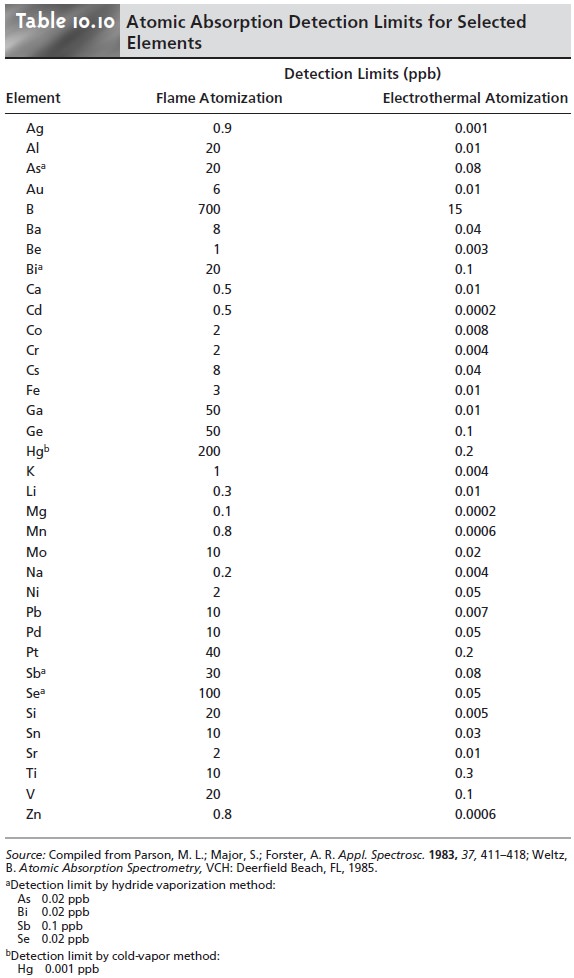

are significantly lower when using electrothermal atomization (Table 10.10).

A better precision when using flame atomization makes it the method of choice when the analyte’s concentration is significantly greater

than the detection limit for flame

atomization. In addition, flame

atomization is subject

to fewer interferences, allows for a greater

throughput of samples, and requires

less expertise from the operator. Electrother- mal atomization is the method of choice when the analyte’s concentration is lower than the

detection limit for flame atomization. Electrothermal atomization is also

useful when the volume of sample is limited.

Selecting the Wavelength and Slit Width

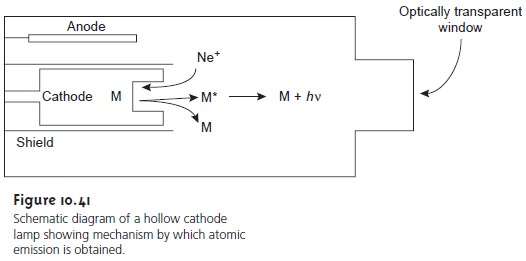

The source for atomic absorption is a hollow cathode

lamp consisting of a cathode

and anode enclosed

within a glass

tube filled with a low pressure

of Ne or Ar (Figure

10.41). When a potential is applied

across the electrodes, the filler

gas is ionized. The positively charged ions collide with the negatively charged

cathode, dislodging, or “sputtering,” atoms

from the cathode’s surface.

Some of the sputtered atoms

are in the excited state

and emit ra- diation characteristic of the metal

from which the cathode was manufactured. By

fashioning the cathode from the metallic analyte, a hollow cathode lamp provides emission lines that correspond to the analyte’s absorption spectrum.

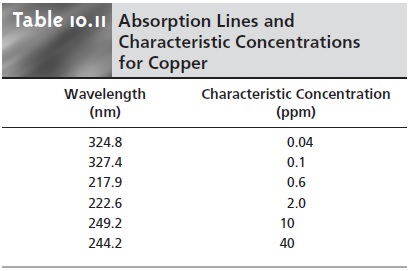

The sensitivity of an atomic

absorption line is often described by its characteris- tic concentration, which is the concentration of analyte giving

an absorbance of 0.00436 (corresponding to a percent transmittance of 99%). For example, Table

10.11 shows a list of wavelengths and

characteristic concentrations for

copper.

Usually the wavelength providing the best sensitivity is used, although a less sensitive wavelength may be more appropriate for a high concentration of analyte. A less sensitive wavelength also may be appropriate when significant interferences occur at the most sensitive wavelength. For example, atomizing a sample produces atoms of not only the analyte, but also of other components present in the sam- ple’s matrix. The presence of other atoms in the flame does not result in an inter- ference unless the absorbance lines for the analyte and the potential interferant are within approximately 0.01 nm. When this is a problem, an interference may be avoided by selecting another wavelength at which the analyte, but not the interfer- ant, absorbs.

The emission spectrum from a hollow

cathode lamp includes, besides emission

lines for the analyte, additional emission lines for impurities present

in the metallic cathode and the filler gas. These additional lines serve as a potential source of stray radiation that may lead to an instrumental deviation

from Beer’s law. Normally the monochromator’s slit width is set as wide as possible, improving

the throughput of radiation, while being narrow

enough to eliminate this source of stray radiation.

Preparing the Sample

Flame and electrothermal atomization require that the sample be in a liquid or solution form.

Samples in solid

form are prepared for analysis by dissolving in an appropriate solvent. When the sample is not soluble,

it may be digested,

either on a hot plate or by microwave, using HNO3, H2SO4, or HClO4. Alternatively, the analyte may be extracted

via a Soxhlet extraction. Liquid samples may be analyzed directly or may

be diluted or extracted if the matrix

is in- compatible with the

method of atomization. Serum samples, for instance, may be difficult to aspirate

when using flame

atomization and may produce unacceptably high background absorbances when using electrothermal

atomization. A liquid–liquid extraction using

an organic solvent

containing a chelating agent is frequently used to concentrate analytes. Dilute solutions of Cd2+, Co2+,

Cu2+, Fe3+, Pb2+,

Ni2+, and

Zn2+, for

example, can be concentrated by extracting with

a solu- tion of ammonium pyrrolidine dithiocarbamate in methyl

isobutyl ketone.

Minimizing Spectral Interference

A spectral interference occurs when an analyte’s absorption line

overlaps with an interferant’s absorption line or band.

As noted pre- viously, the overlap of two atomic absorption lines is seldom a problem.

On the other hand,

a molecule’s broad

absorption band or the scattering of source radia- tion is a potentially serious spectral interference.

An important

question to consider

when using a flame as an atomization source, is how to correct for the absorption of radiation by the flame. The prod- ucts of combustion consist

of molecular species

that may exhibit

broad-band ab- sorption, as well as particulate material that may scatter radiation from the source.

If this spectral interference is not corrected, then the intensity of the transmitted radiation decreases. The result

is an apparent increase in the sam- ple’s absorbance. Fortunately,

absorption and scattering of radiation by the flame are corrected by analyzing

a blank.

Spectral interferences also occur when components of the sample’s

matrix react in the flame

to form molecular species, such as oxides and hydroxides. Ab- sorption and scattering due to components in the sample

matrix other than the analyte constitute the sample’s background and may

present a significant prob- lem, particularly at wavelengths below

300 nm, at which the

scattering of radia-

tion becomes more important. If the composition of the sample’s matrix is known, then standards can be prepared

with an identical matrix. In this case the background

absorption is the same for both the samples and standards. Alterna- tively, if the background is due to a known

matrix component, then that compo-

nent can be added in excess to all samples

and standards so that the

contribution of the naturally occurring interferant is insignificant.

Finally, many interferences due to the

sample’s matrix can

be eliminated by adjusting the

flame’s composi- tion. For example, by switching to a higher

temperature flame it may be possible

to prevent the formation of interfering oxides

and hydroxides.

When the identity

of the matrix interference is unknown, or when it is impossi- ble to adjust the flame to eliminate the interference, then other means

must be used to

compensate for the background interference. Several methods have been devel- oped to compensate for

matrix interferences, and

most atomic absorption spec- trophotometers include one

or more of these methods.

One of the most common methods for background correction is the use of a continuum source, such as a D2 lamp. Since the D2 lamp is a continuum source, the absorbance of its radiation by the analyte’s narrow absorption line

is negligible. Any absorbance of radiation from the D2 lamp, therefore, is due to the

background. Absorbance of radiation from the hollow

cathode lamp, how- ever, is due to both the analyte and the background. Subtracting the absorbance for the D2 lamp

from that for the hollow

cathode lamp gives

an absorbance that has

been corrected for the background interference. Although this method of background

correction may

be quite effective,

it assumes that the background

absorbance is constant

over the range

of wavelengths passed

by the monochro- mator. When this is untrue, subtracting the two absorbances may under- or over-correct

for the background.

Other methods of background correction have been developed, including Zee- man effect background correction and Smith–Hieftje background correction, both of which are included

in some commercially available atomic absorption spec- trophotometers.

Minimizing Chemical Interferences

The quantitative analysis of some elements is complicated by chemical interferences occurring during

atomization. The two most common chemical

interferences are the formation of nonvolatile com- pounds containing the analyte and ionization of the analyte.

One example of a

chemical interference due to the formation of nonvolatile compounds is ob- served when PO43– or

Al3+ is

added to solutions

of Ca2+. In one study, for exam- ple, adding 100 ppm Al3+ to a solution

of 5 ppm Ca2+ decreased the calcium

ion’s absorbance from

0.50 to 0.14,

whereas adding 500

ppm PO43– to a similar solution of Ca2+ decreased the absorbance from 0.50 to 0.38.21 These interfer- ences were attributed to the formation

of refractory particles

of Ca3(PO4)2 and an

Al–Ca–O oxide.

The formation of nonvolatile compounds often can be minimized by increas-

ing the temperature of the

flame, either by changing the

fuel-to-oxidant ratio or by

switching to a different combination of fuel and oxidant. Another

approach is to add

a releasing agent

or protecting agent

to solutions containing the analyte. A releasing agent is a species whose

reaction with the interferent is more favorable than that of the analyte. Adding

Sr2+ or La3+ to solutions of Ca2+, for example,

minimizes the effect of PO43– and Al3+ by reacting

in place of the analyte.

Thus, adding 2000 ppm SrCl2 to the Ca2+/PO43– and Ca2+/Al3+ mixtures discussed in the preceding paragraph gave absorbances for each of 0.48, whereas

a solution of 2000 ppm SrCl2 and Ca2+ alone gave an absorbance of 0.49. Protecting agents

react with the analyte to form a stable volatile

complex. Adding 1% w/w EDTA to

the Ca2+/PO43– solution discussed in the preceding paragraph

gave an absorbance of 0.52, compared

with an absorbance of 0.55 for just the Ca2+ and EDTA. On the other hand, EDTA does not serve as a protecting agent for solutions

of Ca2+ and Al3+.

Ionization interferences occur

when thermal energy

from the flame

or elec- trothermal atomizer

is sufficient to ionize the analyte

10.28

10.28

where M is the analyte

in atomic form,

and M+

is the cation

of the analyte

formed by ionization. Since

the absorption spectra

for M and M+ are different, the position of the equilibrium in reaction 10.28

affects absorbance at wavelengths where

M ab- sorbs. If another species

is present that ionizes more easily than M, then the equilib- rium in reaction 10.28

shifts to the left. Variations in the concentration of easily ionized species,

therefore, may have a significant effect on a sample’s absorbance, resulting in a determinate error. The effect of ionization can be minimized by adding a high concentration of an ionization suppressor, which is simply

another species that ionizes

more easily than the analyte.

If the concentration of the ioniza-

tion suppressor is sufficient, then the increased concentration of electrons in

the flame pushes reaction

10.28 to the left, preventing the analyte’s ionization. Potas- sium and cesium

are frequently used as ionization suppressors because of their low ionization energy.

Standardizing the Method

Because Beer’s law also applies to atomic absorp- tion, we might expect

atomic absorption calibration curves to be linear. In prac-

tice, however, most atomic absorption calibration curves are nonlinear, or linear for

only a limited

range of concentrations. Nonlinearity in atomic

absorption is a consequence of instrumental limitations, including stray radiation from the hol- low cathode lamp and a nonconstant molar absorptivity due to the narrow width of

the absorption line. Accurate

quantitative work, therefore, often requires a suitable means for computing the calibration curve

from a set

of standards. Non- linear calibration curves may be fit using quadratic and cubic equations, al- though neither

works well over

a broad range

of concentrations.

When possible, a quantitative analysis is best conducted using external stan- dards. Unfortunately, matrix interferences are a frequent problem, particularly when using electrothermal atomization. For this reason the method of standard additions is often used. One limitation to this method of standardization, however, is the re- quirement that there be a linear relationship between absorbance and concentration.

Related Topics