Chapter: Modern Analytical Chemistry: Spectroscopic Methods of Analysis

Instrumentation - Atomic Absorption Spectroscopy

Instrumentation

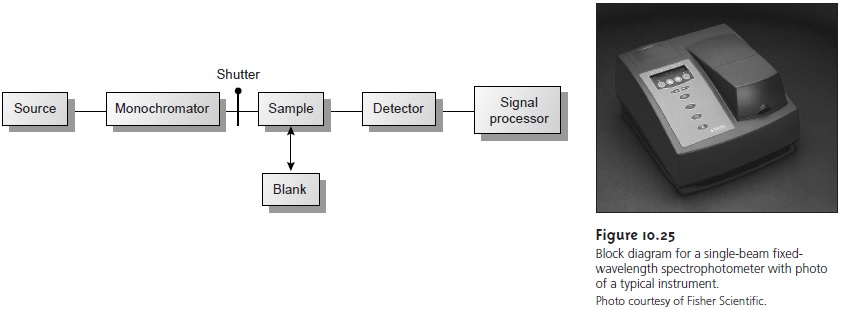

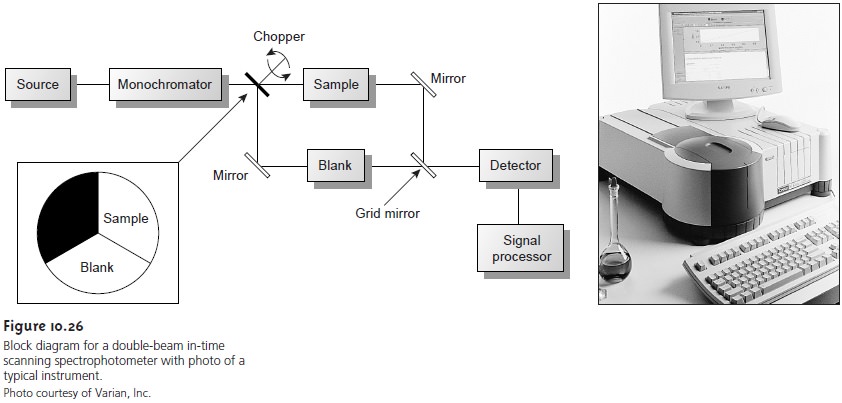

Atomic absorption spectrophotometers (Figure

10.37) are designed using either the single-beam or double-beam optics

described earlier for

molecular absorption spec- trophotometers (see Figures 10.25 and 10.26).

There are, however,

several impor- tant differences that are considered in this section.

Atomization

The most important difference between a spectrophotometer for atomic absorption and one for molecular absorption is the need to convert

the ana- lyte into

a free atom.

The process of converting an analyte in solid, liquid,

or solu- tion form to a free gaseous

atom is called

atomization. In

most cases the sample

containing the analyte undergoes some form of sample preparation that leaves the analyte in an organic

or aqueous solution.

For this reason,

only the introduction of solution samples is considered in this text. Two general

methods of atomization are used: flame atomization and electrothermal atomization. A few elements

are atom- ized using other methods.

Flame Atomizers

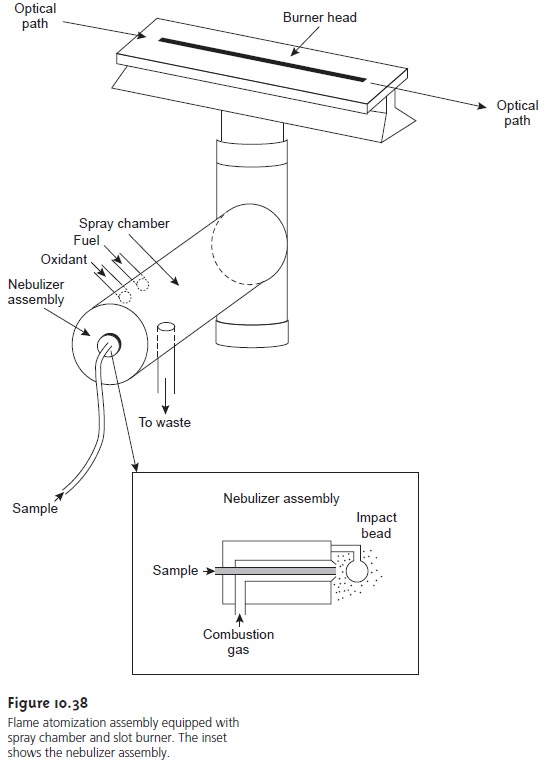

In flame atomization the sample is first converted into a fine mist consisting of small droplets of solution. This is accomplished using a nebulizer assembly similar to that shown in the inset to Figure 10.38. The sample is aspirated into a spray chamber by passing a high-pressure stream consisting of one or more combustion gases, past the end of a capillary tube immersed in the sample. The im- pact of the sample with the glass impact bead produces an aerosol mist.

The aerosol mist mixes with the combustion gases in the spray chamber

before passing to the

burner where the flame’s thermal

energy desolvates the

aerosol mist to a dry

aerosol of small, solid

particles. Subsequently, thermal

energy volatilizes the

particles, pro- ducing a vapor consisting of molecular species, ionic species, and

free atoms.

Thermal

energy

in

flame

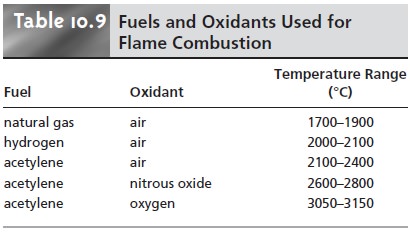

atomization is provided by the combustion of a fuel–oxidant

mixture. Common fuels and oxidants and their normal temperature ranges are listed in Table 10.9.

Of these, the air–acetylene and nitrous oxide-acetylene flames are used most frequently. Normally, the fuel and oxidant are mixed in an ap- proximately stoichiometric ratio; however, a fuel-rich mixture

may be desirable for atoms

that are easily

oxidized. The most

common design for

the burner is the slot burner shown in Figure

10.38. This burner

provides a long

path length for

monitoring absorbance and a stable flame.

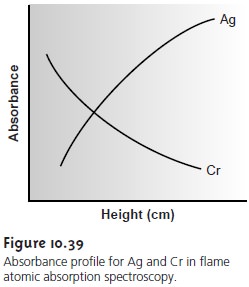

The burner is mounted on an adjustable stage that allows the entire burner as- sembly to move horizontally and vertically. Horizontal adjustment is necessary to ensure that the flame is aligned with the instrument’s optical path. Vertical adjust- ments are needed to adjust the height within the flame from which absorbance is monitored.

This is important because

two competing processes affect the concen- tration of free atoms

in the flame. An increased residence time in the flame

results in a greater

atomization efficiency; thus,

the production of free atoms

increases with height. On the other hand, longer residence times may lead to the formation of metal

oxides that absorb at a wavelength different

from that of the atom. For easily oxidized metals, such as Cr, the concentration of free atoms

is greatest just above

the burner head. For metals,

such as Ag, which are difficult to oxidize, the concen-

tration of free atoms increases steadily with height

(Figure 10.39). Other

atoms show concentration profiles

that maximize at a characteristic height.

The most common

means for introducing samples into a flame atomizer

is continuous aspiration, in which the

sample is continuously passed through the burner

while monitoring the absorbance. Continuous aspiration is sample-

intensive, typically requiring 2–5 mL of sample. Flame

microsampling provides a means

for introducing a discrete sample

of fixed volume

and is useful when the volume of sample is limited or when the sample’s matrix

is incompatible with the

flame atomizer. For

example, the continuous aspiration of a sample contain- ing a high concentration of dissolved solids,

such as sea water, may result in the build-up of solid deposits

on the burner head. These

deposits partially obstruct the flame, lowering the

absorbance. Flame microsampling is accomplished using a micropipet to place

50–250 μL of sample in a Teflon

funnel connected to the nebulizer, or by dipping

the nebulizer tubing

into the sample

for a short time. Dip sampling is usually accomplished with an automatic sampler. The signal

for flame microsampling is a transitory peak whose height

or area is proportional to the

amount of analyte

that is injected.

The principal advantage of flame atomization is the reproducibility with which the sample

is introduced into the spectrophotometer. A significant disadvantage to flame atomizers is that the efficiency of atomization may be quite

poor. This may occur for two reasons.

First, the majority

of the aerosol mist produced

during nebu- lization consists

of droplets that are too large to be carried

to the flame by the com-

bustion gases. Consequently, as much as 95% of the sample

never reaches the

flame. A second reason

for poor atomization efficiency is that the large

volume of combus- tion gases significantly dilutes

the sample. Together, these contributions to the effi- ciency of atomization reduce

sensitivity since the

analyte’s concentration in the

flame may be only 2.5 x 10–6 of that

in solution.

Electrothermal Atomizers

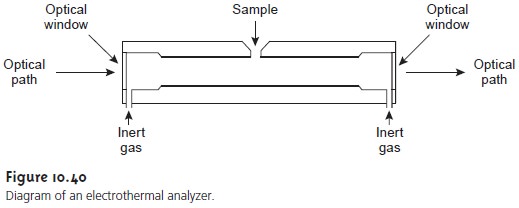

A significant improvement in sensitivity is achieved by using resistive heating in place of a flame. A typical electrothermal atomizer, also known as a graphite furnace, consists of a cylindrical graphite tube approximately 1-3 cm in length, and 3-8 mm in diameter (Figure 10.40).

The graphite tube is

housed in an assembly that

seals the ends

of the tube

with optically transparent win- dows. The assembly

also allows for the passage

of a continuous stream of inert gas, protecting the graphite tube from

oxidation, and removing the gaseous products produced during atomization. A power supply

is used to pass a current through

the graphite tube, resulting in resistive heating.

Samples between 5 and 50 μL are injected into the graphite

tube through a small-diameter hole located at the top of the tube. Atomization is achieved in three

stages. In the first stage

the sample is dried using

a current that

raises the tempera- ture of the graphite tube to about

110 °C. Desolvation leaves the sample

as a solid residue. In the

second stage, which

is called ashing,

the temperature is increased to 350–1200 °C. At these

temperatures, any organic

material in the sample is con-

verted to CO2 and H2O, and volatile inorganic

materials are vaporized. These gases are removed

by the inert gas flow. In the final stage the sample is atomized

by rapidly increasing the temperature to 2000–3000 °C. The result is a transient ab-

sorbance peak whose height or area is proportional to the absolute

amount of ana- lyte

injected into the graphite tube. The three stages are complete in approximately

45–90 s, with most of this time

used for drying

and ashing the

sample.

Electrothermal atomization provides a significant improvement in

sensitivity by trapping the gaseous analyte

in the small volume of the graphite

tube. The ana- lyte’s concentration in the resulting vapor

phase may be as much as 1000 times

greater than that produced by flame atomization. The improvement in sensitivity, and the

resulting improvement in detection limits,

is offset by a significant decrease in precision. Atomization efficiency is strongly

influenced by the sample’s contact

with the graphite tube, which

is difficult to control reproducibly.

Miscellaneous Atomization Methods

A few elements

may be atomized by a chemi-

cal reaction that produces a volatile product.

Elements such as As, Se, Sb, Bi, Ge, Sn, Te,

and Pb form volatile hydrides

when reacted with NaBH4 in acid. An inert gas carries the volatile hydrides

to either a flame or to a heated quartz observation tube situated in the optical

path. Mercury is determined by the cold-vapor method in which it is reduced

to elemental mercury

with SnCl2. The volatile Hg is carried

by an inert gas to an unheated observation tube situated in the instrument’s optical path.

Related Topics