Chapter: Embedded Systems

Elements of Embedded Systems

ELEMENTS

OF EMBEDDED SYSTEMS

Unit

Structure

Objectives

1. Introduction

2. Elements of Embedded Systems.

3. Case studies (examples)

Washing machine

Microwave owen

Automotive Embedded System (AES)

4. Review questions

5. References & further reading

OBJECTIVES

After learning this chapter you will be able to:

Define and describe the elements of an embedded

system

Understand how embedded system works with the

help of two case studies:

Washing

Machine

Microwave

Owen

1. INTRODUCTION

The previous chapter was an introduction to the

world of embedded systems and helped us define what is an embedded system.

This chapter introduces us to the elements of an

embedded system and explains how embedded system works with the help of two

case studies.

2. ELEMENTS

OF EMBEDDED SYSTEMS.

As defined earlier, an embedded system is a

combination of 3 things:

Hardware

Software

Mechanical Components

And it is supposed to do one specific task only.

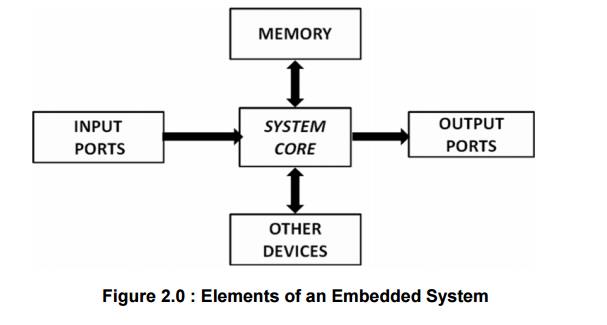

Diagrammatically an embedded system can be

represented as follows:

Embedded

systems are basically designed to regulate a physical variable (such Microwave

Oven) or to manipulate the state of some devices by sending some signals to the

actuators or devices connected to the output port system (such as temperature

in Air Conditioner), in response to the input signal provided by the end users

or sensors which are connected to the input ports.

Hence the

embedded systems can be viewed as a reactive system.

Examples

of common user interface input devices are keyboards, push button, switches,

etc.

The memory

of the system is responsible for holding the code (control algorithm and other

important configuration details).

An

embedded system without code (i.e. the control algorithm) implemented memory

has all the peripherals but is not capable of making decisions depending on the

situational as well as real world changes.

Memory for

implementing the code may be present on the processor or may be implemented as a

separate chip interfacing the processor In a controller based embedded system,

the controller may contain internal memory for storing code

Such controllers are called Micro-controllers

with on-chip ROM, eg. Atmel AT89C51.

3. CASE

STUDIES (EXAMPLES)

Here are some case studies on some commonly used

embedded systems that will help to better understand the concept.

3.1 Washing Machine

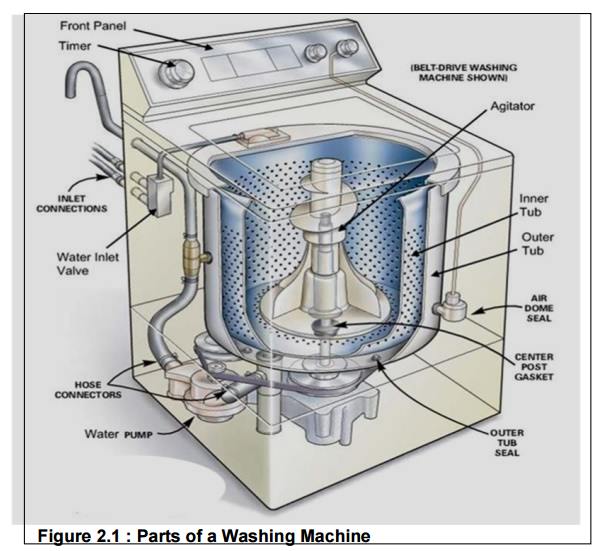

Let us see the important parts of the washing

machine; this will also help us understand the working of the washing machine:

Water

inlet control valve: Near the

water inlet point of the washing

there is water inlet control valve. When you load the clothes in washing

machine, this valve gets opened automatically and it closes automatically

depending on the total quantity of the water required. The water control valve

is actually the solenoid valve.

Water

pump: The water pump circulates water through the washing machine. It works in two

directions, re-circulating the water during wash cycle and draining the water

during the spin cycle.

Tub: There are two types of tubs in the washing washing machine: inner and outer. The clothes are loaded in the inner tub,

where the clothes are washed, rinsed and dried. The inner tub has small holes

for draining the water. The external tub covers theinner tub and supports it

during various cycles of clothes washing.

Agitator or rotating disc: The agitator is located inside the tub of the washing machine. It is the

important part of the washing machine that actually performs the cleaning

operation of the clothes. During the wash cycle the agitator rotates

continuously and produces strong rotating currents within the water due to

which the clothes also rotate inside the tub. The rotation of the clothes

within water containing the detergent enables the removal of the dirt particles

from the fabric of the clothes. Thus the agitator produces most important

function of rubbing the clothes with each other as well as with water.

In some washing machines, instead of the long agitator,

there is a disc that contains blades on its upper side. The rotation of the

disc and the blades produce strong currents within the water and the rubbing of

clothes that helps in removing the dirt from clothes.

Motor of the washing machine: The motor is coupled to the agitator or the disc and produces it

rotator motion. These are multispeed motors, whose speed can be changed as per

the requirement. In the fully automatic washing machine the speed of the motor

i.e. the agitator changes automatically as per the load on the washing machine.

Timer: The timer helps setting the wash time for the

clothes manually. In the automatic

mode the time is set automatically depending upon the number of clothes inside

the washing machine.

Printed

circuit board (PCB): The PCB

comprises of the various electronic

components and circuits, which are programmed to perform in unique ways

depending on the load conditions (the condition and the amount of clothes

loaded in the washing machine). They are sort of artificial intelligence

devices that sense the various external conditions and take the decisions

accordingly. These are also called as fuzzy logic systems. Thus the PCB will

calculate the total weight of the clothes, and find out the quantity of water

and detergent required, and the total time required for washing the clothes.

Then they will decide the time required for washing and rinsing. The entire

processing is done on a kind of processor which may be a microprocessor or

microcontroller.

Drain pipe: The drain pipe enables removing the dirty water from the washing that has been used for the washing purpose.

3.2

Microwave Owen

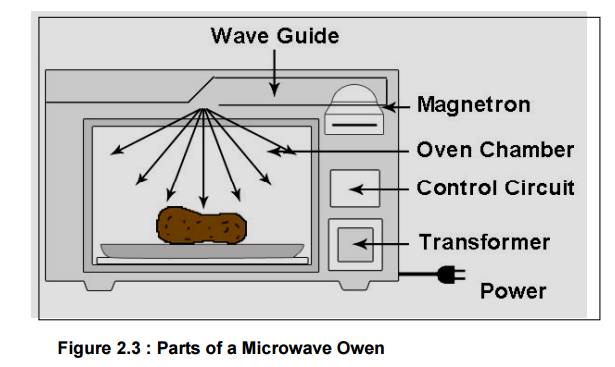

Let us see the important parts of the microwave

oven; this will also help us understand the working of the washing machine:

A microwave oven consists of:

A high voltage transformer, which passes energy

to the magnetron

A cavity magnetron,

A Control circuit with a microcontroller,

A waveguide, and

A cooking chamber

A Transformer transfers electrical energy

through a circuit by magnetic coupling without using motion between parts.

These are used for supplying power to the magnetron.

A Cavity

magnetron is a microwave antenna placed in a vacuum tube and oscillated in

an electromagnetic field in order to produce high GHz microwaves. Magnetrons

are used in microwave ovens and radar systems.

A control

circuit with a microcontroller is integrated on a circuit board. The

microcontroller controls the waveguide and the entire unit so the microwaves

are emitted at a constant rate.

A Waveguide

is any linear structure that guides electromagnetic waves for the purpose of

transmitting power or signals. Generally constructed of a hollow metal pipe.

Placing a waveguide into a vacuum causes radio waves to scatter.

A Cooking

Chamber is a microwave safe container the prevents microwaves from

escaping. The door has a microwave proof mesh with holes that are just small

enough that microwaves can't pass through but lightwaves can. The cooking

chamber itself is a Faraday cage enclosure which prevents the microwaves from

escaping into the environment. The oven door is usually a glass panel for easy

viewing, but has a layer of conductive mesh to maintain the shielding.

3.3 Automotive Embedded System (AES)

The Automotive industry is one of the major application

domains of embedded systems.

Automotive embedded systems are the one where

electronics take control over the mechanical system. Ex. Simple viper control.

The number of embedded controllers in a normal

vehicle varies somewhere between 20 to 40 and can easily be between 75 to 100

for more sophisticated vehicles.

One of the first and very popular use of

embedded system in automotive industry was microprocessor based fuel injection.

Some of the other uses of embedded controllers

in a vehicle are listed below:

Air Conditioner

Engine Control

Fan Control

Headlamp Control

Automatic break system control

Wiper control

Air bag control

Power Windows

AES are normally built around microcontrollers

or DSPs or a hybrid of the two and are generally known as Electronic Control

Units (ECUs).

Types

Of Electronic Control Units(ECU)

High-speed Electronic Control Units (HECUs):

HECUs are

deployed in critical control units requiring fast response.

They

Include fuel injection systems, antilock brake systems, engine control,

electronic throttle, steering controls, transmission control and central

control units.

Low Speed Electronic Control Units (LECUs):-

They are

deployed in applications where response time is not so critical.

They are

built around low cost microprocessors and microcontrollers and digital signal

processors.

Audio

controller, passenger and driver door locks, door glass control etc.

Automotive Communication Buses

Embedded system used inside an automobile

communicate with each other using serial buses. This reduces the wiring

required.

Following are the different types of serial

Interfaces used in automotive embedded applications:

Controller Area Network (CAN):-

CAN bus

was originally proposed by Robert Bosch.

It

supports medium speed and high speed data transfer

CAN is an

event driven protocol interface with support for error handling in data

transmission.

Local Interconnect Network (LIN):-

LIN bus is single master multiple slave communication interface with

support for data rates up to 20 Kbps and is used for sensor/actuator

interfacing

LIN bus

follows the master communication triggering to eliminate the bus arbitration

problem

LIN bus applications

are mirror controls , fan controls , seat positioning controls

Media-Oriented System Transport(MOST):-

MOST is

targeted for automotive audio/video equipment interfacing

A MOST bus

is a multimedia fiber optics point–to-point network implemented in a star ,

ring or daisy chained topology over optical fiber cables.

MOST bus

specifications define the physical as well as application layer , network layer

and media access control.

Related Topics