Chapter: Embedded Systems Design

What is an embedded system?

What is an embedded system?

Whenever the word microprocessor is mentioned, it con-jures up a picture

of a desktop or laptop PC running an application such as a word processor or a

spreadsheet. While this is a popular application for microprocessors, it is not

the only one and the fact is most people use them indirectly in common objects

and appli-ances without realising it. Without the microprocessor, these

products would not be as sophisticated or cheap as they are today.

The embedding of microprocessors into equipment and consumer appliances

started before the appearance of the PC and consumes the majority of

microprocessors that are made today. In this way, embedded microprocessors are

more deeply ingrained into everyday life than any other electronic circuit that

is made. A large car may have over 50 microprocessors controlling functions

such as the engine through engine management systems, brakes with electronic

anti-lock brakes, transmission with traction con-trol and electronically

controlled gearboxes, safety with airbag systems, electric windows,

air-conditioning and so on. With a well-equipped car, nearly every aspect has

some form of elec-tronic control associated with it and thus a need for a

microproc-essor within an embedded system.

A washing machine may have a microcontroller that con-tains the

different washing programs, provides the power control for the various motors

and pumps and even controls the display that tells you how the wash cycles are

proceeding.

Mobile phones contain more processing power than a desk-top processor of

a few years ago. Many toys contain microproces-sors and there are even kitchen

appliances such as bread machines that use microprocessor-based control systems.

The word control is very apt for embedded systems because in virtually every

embedded system application, the goal is to control an aspect of a physical

system such as temperature, motion, and so on using a variety of inputs. With

the recent advent of the digital age replac-ing many of the analogue

technologies in the consumer world, the dominance of the embedded system is

ever greater. Each digital consumer device such as a digital camera, DVD or MP3

player all depend on an embedded system to realise the system. As a result, the

skills behind embedded systems design are as diverse as the systems that have

been built although they share a common heritage.

What is an embedded system?

There are many definitions for this but the best way to define it is to

describe it in terms of what it is not and with examples of how it is used.

An embedded system is a microprocessor-based system that is built to

control a function or range of functions and is not designed to be programmed

by the end user in the same way that a PC is. Yes, a user can make choices

concerning functionality but cannot change the functionality of the system by

adding/replac-ing software. With a PC, this is exactly what a user can do: one

minute the PC is a word processor and the next it’s a games machine simply by

changing the software. An embedded system is designed to perform one particular

task albeit with choices and different options. The last point is important

because it differenti-ates itself from the world of the PC where the end user

does reprogram it whenever a different software package is bought and run.

However, PCs have provided an easily accessible source of hardware and software

for embedded systems and it should be no surprise that they form the basis of

many embedded systems. To reflect this, a very detailed design example is

included at the end of this book that uses a PC in this way to build a

sophisticated data logging system for a race car.

If this need to control the physical world is so great, what is so

special about embedded systems that has led to the widespread use of

microprocessors? There are several major reasons and these have increased over

the years as the technology has progressed and developed.

Replacement for discrete logic-based circuits

The microprocessor came about almost by accident as a programmable

replacement for calculator chips in the 1970s. Up to this point, most control

systems using digital logic were imple-mented using individual logic integrated

circuits to create the design and as more functionality became available, the

number of chips was reduced.

This was the original reason for a replacement for digital systems

constructed from logic circuits. The microprocessor was originally developed to

replace a mass of logic that was used to create the first electronic

calculators in the early 1970s. For exam-ple, the early calculators were made

from discrete logic chips and many hundreds were needed just to create a simple

four function calculator. As the integrated circuit developed, the individual

logic functions were integrated to create higher level functions. Instead of

creating an adder from individual logic gates, a com-plete adder could be

bought in one package. It was not long before complete calculators were

integrated onto a single chip. This enabled them to be built at a very low cost

compared to the original machines but any changes or improvements required that

a new chip be developed. The answer was to build a chip that had some form of

programmable capability within it. Why not build a chip that took data in,

processed it and sent it out again? In this way, instead of creating new

functions by analysing the gate level logic and modifying it — a very

time-consuming process — new products could be created by changing the program

code that processed the information. Thus the microprocessor was born.

Provide functional upgrades

In the same way that the need to develop new calculator chips faster and

with less cost prompted the development of the first microprocessors, the need

to add or remove functionality from embedded system designs is even more

important. With much of the system’s functionality encapsulated in the software

that runs in the system, it is possible to change and upgrade systems by

changing the software while keeping the hardware the same. This reduces the

cost of production even lower because many different systems can share the same

hardware base.

In some cases, this process is not possible or worthwhile but allows the

manufacturer to develop new products far quicker and faster. Examples of this

include timers and control panels for domestic appliances such as VCRs and

televisions.

In other cases, the system can be upgraded to improve functionality.

This is frequently done with machine tools, tel-ephone switchboards and so on.

The key here is that the ability to add functionality now no longer depends on

changing the hard-ware but can be done by simply changing the software. If the

system is connected to a communications link such as a telephone or PC network,

then the upgrade can be done remotely without having to physically send out an

engineer or technician.

Provide easy maintenance upgrades

The same mechanism that allows new functionality to be added through

reprogramming is also beneficial in allowing bugs to be solved through changing

software. Again it can reduce the need for expensive repairs and modifications

to the hardware.

Improves mechanical performance

For any electromechanical system, the ability to offer a finer degree of

control is important. It can prevent excessive mechanical wear, better control

and diagnostics and, in some cases, actually compensate for mechanical wear and

tear. A good example of this is the engine management system. Here, an embedded

microproc-essor controls the fuel mixture and ignition for the engine and will

alter the parameters and timing depending on inputs from the engine such as

temperature, the accelerator position and so on. In this way, the engine is

controlled far more efficiently and can be configured for different environments

like power, torque, fuel efficiency and so on. As the engine components wear,

it can even adjust the parameters to compensate accordingly or if they are

dramatically out of spec, flag up the error to the driver or indicate that

servicing is needed.

This level of control is demonstrated by the market in ‘chipped’ engine

management units where third party companies modify the software within the

control unit to provide more power or torque. The differences can range from

10% to nearly 50% for some turbo charged engines! All this from simply

chang-ing a few bytes. Needless to say, this practice may invalidate any

guarantee from the manufacturer and may unduly stress and limit the engine’s

mechanical life. In some cases, it may even infringe the original

manufacturer’s intellectual property rights.

Protection of intellectual property

To retain a competitive edge, it is important to keep the design

knowledge within the company and prevent others from understanding exactly what

makes a product function. This knowl-edge, often referred to as IPR

(intellectual property rights), be-comes all important as markets become more

competitive. With a design that is completely hardware based and built from

off-the-shelf components, it can be difficult to protect the IPR that was used

in its design. All that is needed to do is to take the product, identify the

chips and how they are connected by tracing the tracks on the circuit board.

Some companies actually grind the part numbers off the integrated circuits to make

it harder to reverse engineer in this way.

With an embedded system, the hardware can be identified but the software

that really supplies the system’s functionality can be hidden and more

difficult to analyse. With self-contained microcontrollers, all that is visible

is a plastic package with a few connections to the outside world. The software

is already burnt into the on-chip memory and is effectively impossible to

access. As a result, the IPR is much more secure and protected.

Replacement for analogue circuits

The movement away from the analogue domain towards digital processing

has gathered pace recently with the advent of high performance and low cost

processing.

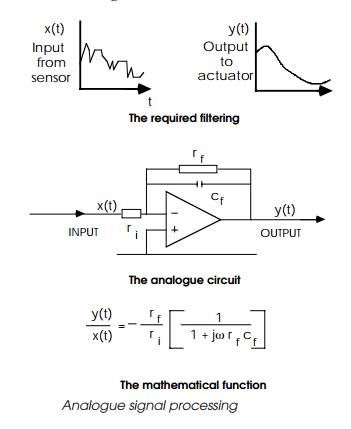

To understand the advantages behind digital signal process-ing, consider

a simple analogue filter. The analogue implementa-tion is extremely simple

compared to its digital equivalent. The analogue filter works by varying the

gain of the operational amplifier which is determined by the relationship

between ri and rf.

In a system with no frequency component, the capacitor ci plays no part as its impedance is far greater than that of rf. As the frequency component increases,

the capacitor impedance de-creases until it is about equal with rf where the effect will be to reduce the

gain of the system. As a result, the amplifier acts as a low pass filter where

high frequencies will be filtered out. The equation shows the relationship

where jω is the

frequency compo-nent. These filters are easy to design and are cheap to build.

By making the CR (capacitor-resistor) network more complex, differ-ent filters

can be designed.

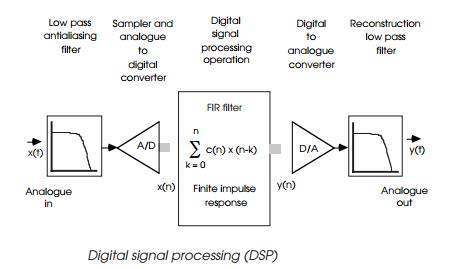

The digital equivalent is more complex requiring several electronic

stages to convert the data, process it and reconstitute the data. The equation

appears to be more involved, comprising of a summation of a range of

calculations using sample data multi-plied by a constant term. These constants

take the place of the CR components in the analogue system and will define the

filter’s transfer function. With digital designs, it is the tables of

coeffi-cients that are dynamically modified to create the different filter

characteristics.

Given the complexity of digital processing, why then use it? The

advantages are many. Digital processing does not suffer from component ageing,

drift or any adjustments which can plague an analogue design. They have high

noise immunity and power supply rejection and due to the embedded processor can

easily provide self-test features. The ability to dynamically modify the

coefficients and therefore the filter characteristics allows complex filters

and other functions to be easily implemented. However, the processing power

needed to complete the ‘multiply–accumulate’ processing of the data does pose

some interesting processing requirements.

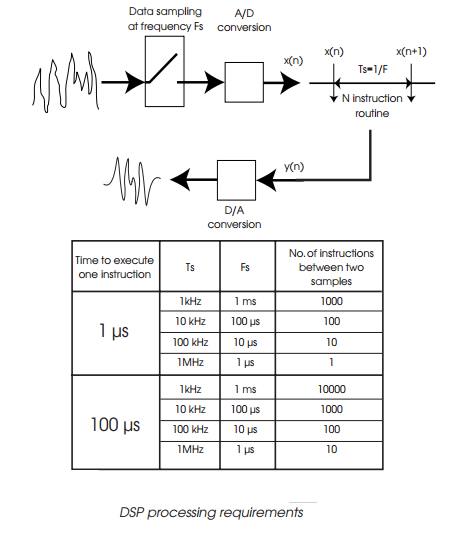

The diagram shows the problem. An analogue signal is sampled at a

frequency fs and is converted by the

A/D converter. This frequency will be first determined by the speed of this

conversion. At every period, ts,

there will be a new sample to process using N

instructions. The table shows the relationship between sampling speed, the

number of instructions and the instruction execution time. It shows that the

faster the sampling frequency, the more processing power is needed. To achieve

the 1 MHz frequency, a 10 MIPS processor is needed whose instruction set is

powerful enough to complete the processing in under 10 instructions. This

analysis does not take into account A/D conver-sion delays. For DSP algorithms,

the sampling speed is usually twice the frequency of the highest frequency

signal being proc-essed: in this case the 1 MHz sample rate would be adequate

for signals up to 500 kHz.

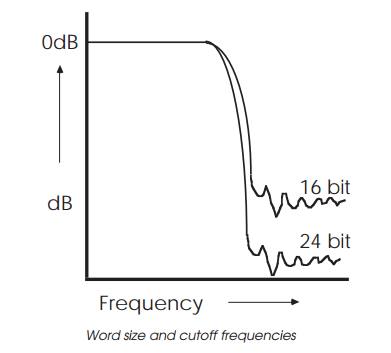

One major difference between analogue and digital filters is the

accuracy and resolution that they offer. Analogue signals may have definite

limits in their range, but have infinite values be-tween that range. Digital

signal processors are forced to represent these infinite variations within a

finite number of steps deter-mined by the number of bits in the word. With an 8

bit word, the increases are in steps of 1/256 of the range. With a 16 bit word,

such steps are in 1/65536 and so on. Depicted graphically as shown, a 16 bit

word would enable a low pass filter with a roll-off of about 90 dB. A 24 bit

word would allow about 120 dB roll-off to be achieved.

DSP can be performed by ordinary microprocessors, al-though their more

general-purpose nature often limits perform-ance and the frequency response.

However, with responses of only a few hundred Hertz, even simple

microcontrollers can perform such tasks. As silicon technology improved,

special build-ing blocks appeared allowing digital signal processors to be

developed, but their implementation was often geared to a hard-ware approach

rather than designing a specific processor architec-ture for the job. It is now

common for processors to claim DSP support through enhanced multiply–accumulate

operations or through special accelerators. It is clear though, that as general

purpose processing increases in capability, what was once the sole province of

a DSP can now be achieved by a general purpose processor.

Related Topics