Chapter: Mechanical : Total Quality Management (TQM) : TQM Tools & Techniques

Total Productive Maintenance

Total Productive Maintenance

Introduction: TPM - History:

TPM is an innovative Japanese concept. The origin of TPM can betraced back to 1951 when preventive maintenance was introduced in Japan. However the concept of preventive maintenance was

taken from USA. Nippondenso was the first company to introduce plant wide preventive maintenance in 1960. Preventive maintenance is the concept wherein, operators produced goods using machines and the maintenance group was dedicated with work of maintaining those machines, however with the automation of Nippondenso, maintenance became a problem as more maintenance personnel were required. So the management decided that the routine maintenance of equipment would be carried out by the operators. (This is Autonomous maintenance, one of the features of TPM). Maintenance group took up only essential maintenance works .Thus Nippondenso which already followed preventive maintenance also added Autonomous maintenance done by production operators.

The maintenance crew went in the equipment modification for improving reliability. The modifications were made or incorporated in new equipment. This leads to maintenance prevention. Thus

preventive maintenance along with Maintenance prevention and Maintainability Improvementgave birth to Productive

maintenance. The aim of productive maintenance was to maximize plant and equipmenteffectiveness to achieve optimum life cycle cost of production equipment. In Total Quality Management, Total Productive Maintenance (TPM) is an important and effective tool for the excellence. Total productive maintenance (TPM) is keeping the current plant and equipment at its highest productivity level through cooperation of all areas of the organization. Generally, the first bridge to cross is to break down the traditional barriers between maintenance and

production personnel so they are working together. Now, Maintenance management is planning, organizing, controlling maintenance activities such that the over all maintenance cost is the minimum. Maintenance is required not only by equipment but also by other facilities such as building, land, garden, lawn etc. Maintenance lawns and garden of the premises of the factory may be important aspects of environment protection especially in process industries. However, maintenance of equipment used directly in the production process is much more important for a business enterprise. Maintenance of facilities and equipment is done to ensure that these are in good working condition at any point of time and if breakdowns occur, necessary repairs should be done in order to bring these back to

running condition as early as possible.

What is Maintenance and Maintenance Management

Maintenance is an initiatives that covers all those operations such as monitoring , inspecting, adjusting, repairing and / or doing whatever is necessary to keep a machine, a facility, a piece of equipment or transportation vehicle in the proper working conditions.

Maintenance Management is reviewing, planning, organizing and controlling maintenance activities such that the overall maintenance cost is the minimum.

Total Productive Maintenance

It can be considered as the medical science of machines. Total Productive Maintenance (TPM) is a maintenance program which involves a newly defined concept for maintaining plants and equipment. TPM seeks to maximize equipments effectiveness throughout the life time of that equipment. It strives to maintain optimum equipment conditions in order to prevent unexpected break downs, speed loses, and quality defects arising from process activities.

The goal of the TPM program is to markedly increase production while, at the same time, increasing employee morale and job satisfaction.

TPM brings maintenance into focus as a necessary and vitally important part of the business. It is no longer regarded as a nonprofit activity. Down time for maintenance is scheduled as a part of the manufacturing day and, in some cases, as an integral part of the manufacturing process.

The goal is to hold emergency and unscheduled maintenance to a minimum.

TPM / The objective of TPM:

TPM was introduced to achieve the following objectives:

• Avoid wastage in a quickly changing economic environment.

• Producing goods without reducing product quality.

• Reduce cost.

• Produce target quantity at the earliest possible time.

• Goods send to the customers must be non defective.

To fulfill those objectives and the goal TPM has dual targets: 1. Zero defects, zero accidents and zero loss; 2. Zero breakdown (100%

equipment availability). It is true that when defects and breakdown are reduced the operating costs come down and hence productivity increases and the products are delivered to the customer at a reasonable cost and at the right time.

Six core principles of TPM:

• Obtain Minimum 90% OEE (Overall Equipment Effectiveness) Run the machines even during lunch.

(Lunch is for operators and not for machines!)

2. Operate in a manner, so that there are no customer complaints.

3. Reduce the manufacturing cost by 30%.

4. Achieve 100% success in delivering the goods as required by the customer.

5. Maintain a accident free environment.

6. Increase the suggestions by 3 times. Develop Multiskilled and flexible workers. Now the question comes -why should we consider TPM is an

effective tech. for continuous Improvement? Because it

Aims to maximize equipment effectiveness – overall effectiveness.

Various departments – engineering, operations, and Maintenance – collectively implement it. Involves every single employee from the top management to

workers in the shop floor.

In TPM the machine operator is responsible for the maintenance of the machine as well as its operation

However, Smart TPM requires the following:

• Restoring equipment to a like – new condition.

• Having operators involved in the maintenance of the equipment.

• Improving maintenance efficiency and effectiveness.

• Training the labour force to improve upon their job skills.

• Equipment management and maintenance prevention, which is considered inherent in the reliability

strategy and

• The effective use of preventive and predictive maintenance technology.

Therefore, the aim of productive maintenance was to maximize plant and equipment effectiveness to achieve optimum life cycle cost of production equipment. In 1971, the Japan Institute of

Plant Maintenance (JIPM) defined TPM as a system of maintenance. JIPM introduced TPM award to respective organization as a standard of quality in 1972.

Motives of TPM

1. Adoption of life cycle approach for improving the overall performance of production equipment.

2. Improving productivity by highly motivated workers which is achieved by job enlargement.

3. The use of voluntary small group activities for identifying the cause of failure, possible plant and equipment modifications.

Uniqueness of TPM

The major difference between TPM and other concepts is that the operators are also made to involve in the maintenance process. The concept of "I ( Production operators ) Operate, You ( Maintenance department ) fix" is not followed.

TPM Objectives

1. Achieve Zero Defects, Zero Breakdown and Zero accidents in all functional areas of the organization.

2. Involve people in all levels of organization.

3. Form different teams to reduce defects and Self Maintenance.

Direct benefits o fTPM

1. Increase productivity and OPE ( Overall Plant Efficiency ) by 1.5 or 2 times.

2. Rectify customer complaints.

3. Reducethe manufacturing cost by 30%.

4. Satisfy the customers needs by 100 % ( Delivering the right quantity at the right time, in the required quality. )

5. Reduce accidents.

6. Follow pollution control measures.

Indirect benefits of TPM

1. Higher confidence level among the employees.

2. Keep the work place clean, neat and attractive.

3. Favorablechange in the attitude of the operators.

4. Achieve goals by working as team.

5. Horizontaldeployment of a new concept in all areas of the organization.

6. Share knowledge and experience.

7. The workers get a feeling of owning the machine.

Steps in introduction of TPM in a organization : 4.23.1 - PREPARATORY STAGE:

STEP 1 - Announcement by Management to all about 4.23.2 TPM introduction in the organization:

Proper understanding, commitment and active involvement of the top management in needed for this step. Senior management should have awareness programmes, after which announcement is made to all. Publish it in the house magazine and put it in the notice board. Send a letter to all concerned individuals if required.

3 - Initial education and propaganda for TPM :

Training is to be done based on the need. Some need intensive training and some just an awareness. Take people who matters to places where TPM already successfully implemented.

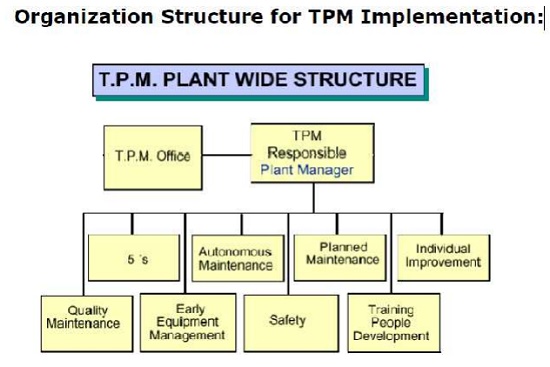

4 - Setting up TPM and departmental committees :

TPM includes improvement, autonomous maintenance, quality maintenance etc., as part of it. When committees are set up it should take care of all those needs.

5 - Establishing the TPM working system and target :

Now each area is benchmarked and fix up a target for achievement.

6 - A master plan for institutionalizing :

Next step is implementation leading to institutionalizing wherein TPM becomes an organizational culture. Achieving PM award is the

proof of reaching a satisfactory level.

STAGE - B - INTRODUCTION STAGE

This is a ceremony and we should invite all. Suppliers as they should know that we want quality supply from them. Related companies and affiliated companies who can be our customers,

sisters concerns etc. Some may learn from us and some can help us and customers will get the communication from us that we care for quality output.

STAGE C - IMPLEMENTATION

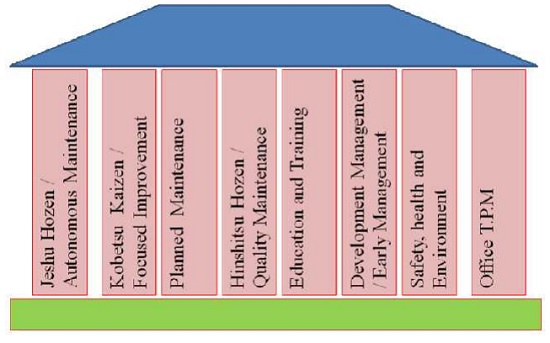

In this stage eight activities are carried which are called eight pillars in the development of TPM activity. Of these four activities are for establishing the system for production efficiency, one for initial control system of new products and equipment, one for improving the efficiency of administration and are for control of safety, sanitation as working environment.

STAGE D - INSTITUTIONALISING STAGE

By all there activities one would has reached maturity stage. Now is the time for applying for PM award. Also think of challenging level to which you can take this movement.

TPM – PILLARS:

PILLAR -1 - JISHU HOZEN ( Autonomous maintenance ) :

This pillar is geared towards developing operators to be able to take care of small maintenance tasks, thus freeing up the skilled maintenance people to spend time on more value added activity

and technical repairs. The operators are responsible for upkeep of their equipment to prevent it from deteriorating.

Policy:

1. Uninterrupted operation of equipments.

2. Flexible operators to operate and maintain other equipments.

3. Eliminating the defects at source through active employee participation.

4. Stepwise implementation of JH activities.

JISHU HOZEN Targets:

1. Prevent the occurrence of 1A / 1B because of JH.

2. Reduce oil consumption by 50%

3. Reduce process time by 50%

4. Increase use of JH by 50%

Steps in JISHU HOZEN :

1. Preparation of employees.

2. Initial cleanup of machines.

3. Take counter measures

4. Fix tentative JH standards

5. General inspection

6. Autonomous inspection

7. Standardization and

8. Autonomous management.

Each of the above mentioned steps is discussed in detail below.

1. Train the Employees : Educate the employees about TPM, Its advantages, JH advantages and Steps in JH. Educate the employees about abnormalities in equipments.

2. Initial cleanup of machines :

o Supervisor and technician should discuss and set a date for implementing step1 o Arrange all items needed for cleaning

o On the arranged date, employees should clean the equipment completely with the help of maintenance department.

o Dust, stains, oils and grease has to be removed.

o Following are the things that has to be taken care while

cleaning. They are Oil leakage, loose wires, unfastened nits and bolts and worn out parts.

o After clean up problems are categorized and suitably tagged. White tags are place where problems can be solved by operators. Pink tag is placed where the aid of maintenance department is needed.

o Contents of tag is transferred to a register. o Make note of area which were inaccessible.

o Finally close the open parts of the machine and run the machine. 3. Counter Measures :

o Inaccessible regions had to be reached easily. E.g. If there are many screw to open a fly wheel door, hinge door can be used. Instead of opening a door for inspecting the machine, acrylic sheets can be used.

o To prevent work out of machine parts necessary action must be taken.

o Machine parts should be modified to prevent accumulation of dirt and dust. 4. Tentative Standard :

o JH schedule has to be made and followed strictly.

o Schedule should be made regarding cleaning, inspection and lubrication and it also should include details like when, what and how.

5. General Inspection :

o The employees are trained in disciplines like Pneumatics, electrical, hydraulics, lubricant and coolant, drives, bolts, nuts and Safety.

o This is necessary to improve the technical skills of employees and to use inspection manuals correctly.

o After acquiring this new knowledge the employees should share this with others.

o By acquiring this new technical knowledge, the operators are now well aware of machine parts. 6. Autonomous Inspection :

o New methods of cleaning and lubricating are used.

o Each employee prepares his own autonomous chart / schedule in consultation with supervisor.

o Parts which have never given any problem or part which don't need any inspection are removed from list permanently based on experience.

o Including good quality machine parts. This avoid defects due to poor JH. o Inspection that is made in preventive maintenance is included in JH.

o The frequency of cleanup and inspection is reduced based on experience. 7. Standardization :

o Upto the previous stem only the machinery / equipment was the concentration. However in this step the surroundings of machinery are organized. Necessary items should be organized, such that there is no searching and searching time is reduced.

o Work environment is modified such that there is no difficulty in getting any item. o Everybody should follow the work instructions strictly.

o Necessary spares for equipments is planned and procured. 8. Autonomous Management :

o OEE and OPE and other TPM targets must be achieved by continuous improve through Kaizen. o PDCA ( Plan, Do, Check and Act ) cycle must be implemented for Kaizen.

PILLAR -2 – KOBETSU KAIZEN :

"Kai" means change, and "Zen" means good ( for the better ). Basically kaizen is for small improvements, but carried out on a continual basis and involve all people in the organization. Kaizen is opposite to big spectacular innovations. Kaizen requires no or little investment. The principle behind is that "a very large number of small improvements are move effective in an organizational environment than a few improvements of large value. This pillar is aimed at reducing losses in the workplace that affect our efficiencies. By using a detailed and thorough procedure we eliminate losses in a systematic method using various Kaizen tools. These activities are not limited to production areas and can be implemented in administrative areas as well.

Kaizen Target:

Achieve and sustain zero loses with respect to minor stops, measurement and adjustments, defects and unavoidable downtimes. It also aims to achieve 30% manufacturing cost reduction.

Tools used in Kaizen:

1. Problem analysis

2. (Root cause ) Why - Why analysis

3. Summary of losses

4. Kaizen register

5. Kaizen summary sheet.

PILLAR -3 - PLANNED MAINTENANCE :

It is aimed to have trouble free machines and equipments producing defect free products for total customer satisfaction. This breaks maintenance down into 4 "families" or groups which was defined earlier.

1. Preventive Maintenance

2. Breakdown Maintenance

3. Corrective Maintenance

4. Maintenance Prevention

With Planned Maintenance we evolve our efforts from a reactive to a proactive method and use trained maintenance staff to help train the operators to better maintain their equipment.

Policy :

1. Achieve and sustain availability of machines

2. Optimum maintenance cost.

3. Reduces spares inventory.

4. Improve reliability and maintainability of machines.

Target :

1. Zero equipment failure and break down.

2. Improve reliability and maintainability by 50 %

3. Reduce maintenance cost by 20 %

4. Ensure availability of spares all the time.

Six steps in Planned maintenance :

1. Equipment evaluation and recoding present status.

2. Restore deterioration and improve weakness.

3. Building up information management system.

4. Prepare time based information system, select equipment, parts and members and map out plan.

5. Prepare predictive maintenance system by introducing equipment diagnostic techniques and

6. Evaluation of planned maintenance.

PILLAR -4 – Hinshitsu Hozen or QUALITY MAINTENANCE :

It is aimed towards customer delight through highest quality through defect free manufacturing. Focus is on eliminating non conformances in a systematic manner, much like Focused

Improvement. We gain understanding of what parts of the equipment affect product quality and begin to eliminate current quality concerns, then move to potential quality concerns. Transition is from reactive to proactive (Quality Control to Quality Assurance). QM activities is to set equipment conditions that preclude quality defects, based on the basic concept of maintaining perfect equipment to maintain perfect quality of products. The condition are checked and measure in time series to very that measure values are within standard values to prevent defects. The transition of measured values is watched to predict possibilities of defects occurring and to take counter measures before hand.

Policy :

1. Defect free conditions and control of equipments.

2. QM activities to support quality assurance.

3. Focus of prevention of defects at source

4. Focus on poka-yoke. ( fool proof system )

5. In-line detection and segregation of defects.

6. Effective implementation of operator quality assurance.

Target :

1. Achieve and sustain customer complaints at zero

2. Reduce in-process defects by 50 %

3. Reduce cost of quality by 50 %.

Pilar – 5: Development Management / Early Management:

Early management or development management helps in drastically reducing the time taken to receive, install, and set – up newly purchased equipments (known as vertical start – up). Early management can also be used for reducing the time to manufacture a new product in the factory.

PILLAR 6 – TRAINING and EDUCATION:

It is aimed to have multi-skilled revitalized employees whose morale is high and who has eager to come to work and perform all required functions effectively and independently. Education is given to operators to upgrade their skill. It is not sufficient know only "Know-How" by they should also learn "Know-why". By experience they gain, "Know-How" to overcome a problem what to be done. This they do without knowing the root cause of the problem and

why they are doing so. Hence it become necessary to train them on knowing "Know-why". The employees should be trained to achieve the four phases of skill. The goal is to create a factory full of experts. The different phase of skills are :

Phase – 1: Do not know

Phase – 2: Know the theory but cannot do. Phase – 3: Can do but can not teach Phase – 4: Can do and also teach

Policy:

1. Focus on improvement of knowledge, skills and techniques.

2. Creating a training environment for self learning based on felt needs.

3. Training curriculum / tools /assessment etc conductive to employee revitalization

4. Training to remove employee fatigue and make work enjoyable.

Target:

1. Achieve and sustain downtime due to want men at zero on critical machines.

2. Achieve and sustain zero losses due to lack of knowledge / skills / techniques

3. Aim for 100 % participation in suggestion scheme.

PILLAR- 7: SAFETY, HEALTH AND ENVIRONMENT Target :

1. Zero accident,

2. Zero health damage

3. Zero fires.

In this area focus is on to create a safe workplace and a surrounding area that is not damaged by our process or procedures. This pillar will play an active role in each of the other pillars on a regular basis.

A committee is constituted for this pillar which comprises representative of officers as well as workers. The committee is headed by Senior vice President ( Technical ). Utmost importance to Safety is given in the plant. Manager (Safety) is looking after functions related to safety. To create awareness among employees various competitions like safety slogans, Quiz, Drama, Posters, etc. related to safety can be organized at regular intervals.

PILLAR -8 : OFFICE TPM

Office TPM should be started after activating four other pillars of TPM (JH, KK, QM, PM). Office TPM must be followed to improve productivity, efficiency in the administrative functions and identify and eliminate losses. This includes analyzing processes and

procedures towards increased office automation. Office TPM addresses twelve major losses. They are

1. Processing loss

2. Cost loss including in areas such as procurement, accounts, marketing, sales leading to high inventories

3. Communication loss

4. Idle loss

5. Set-up loss

6. Accuracy loss

7. Office equipment breakdown

8. Communication channel breakdown, telephone and fax lines

9. Time spent on retrieval of information

10.Non availability of correct on line stock status

11.Customer complaints due to logistics

12.Expenses on emergency dispatches/purchases

Conclusion:

Today, with competition in industry at an all time high, TPM may be the only thing that stands between success and total failure for some companies. It has been proven to be a program that works. It can be adapted to work not only in industrial plants, but in construction, building maintenance, transportation, and in a variety of other situations. Employees must be educated and convinced that TPM is not just another "program of the month" and that management is totally committed to the

program and the extended time frame necessary for full implementation. If everyone involved

in a TPM program does his or her part, an unusually high rate of returncompared to resour may be expected

Related Topics