Chapter: Mechanical : Total Quality Management (TQM) : TQM Tools & Techniques

New Seven management Tools

New Seven

management Tools

It is a simple and effective tool. This approach

focuses on the process (to reveal the causes), rather than the people.

Example: Why was there a delay in dispatch

of good? Cutting tool failed, resulting in delay in manufacture. Why?

The tools were reused?

Why?

Ordered tool were not delivered?

Solution

changes the dispatch schedule, if ever the tools were not delivered.

Forced

Field Analysis

ReadersŌĆÖ

attention is invited to the discussion in Chapter 2 on this topic.

Nominal

Group Technique

This technique provides for ideas input from every

one in the team and for effective decision making.

A team wants to decide upon a current complaint to

attend. Every one in the team writes the problem on a paper, what they think is

most important. They are listed in a chart and then the team members are asked

to rank, from most important to least important. The ranking are given a

numerical value starting from, say, on a 10 to 1 scale. Points for each problem

is totaled and the ones with highest number of points, is considered o be the

most important.

The seven advanced tools of quality management or

the ŌĆśNew SevenŌĆÖ is a collection of tools put together by a set of

Japanese quality professionals. , Arrow Diagram, was known to engineers and

project managers by names like PERT (Programme Evaluation and Review Technique)

or CMP (Critical Mean Path). Another tool in this set PDPC (Process Decision

Programme Chart) has been used in operations research.

CONCEPT

These tools, unlike SPC tools are qualitative tools. Most of

these tools do not involve the use of numerical data.

. Like

all management tools these are judgmental tools.

Managers are often called upon to make decisions based on

their judgement with help of incomplete information or on subjective issues.

Team work

and techniques like brainstorming are very essential for best results with such

tools.

The seven

tools we will see are :

1. Affinity

diagram

2. Relations

diagram

3. Tree

diagram

4. Matrix

diagram

5. Matrix

data analysis diagram .

6

.Process decision programme chart

7. Arrow

diagram

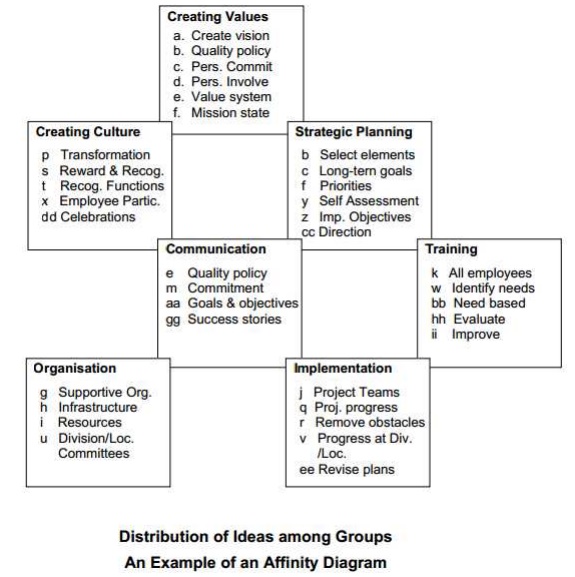

Affinity

Diagram

The purpose of an affinity diagram is to provide a visual

representation of grouping of a large number of ideas or factors or

requirements into logical sets of related items to help one organise action

plans in a systematic manner.

Procedure

The steps

in the procedure for preparing an affinity diagram are :

1. Decide

the subject or the topic

2. Generate a

large number of ideas through brainstorming

3. Decide

the number of groups and their titles. Create a card for each group. Enter the

title of the group at the top of the card.

4. Distribute

all the ideas among the cards. If necessary, create new cards for additional

groups.

5. Arrange

the cards according to the relationship between the groups.

6. Give a

name to the affinity diagram.

Applications:

The structure and the procedure for affinity diagram would

have shown how simple the tool is. Its simplicity makes it easy to combine it

with other tools and put it to a wide variety of applications. For instance, it

can be combined with a cause-and-effect diagram or a relations diagram to

identify and regroup causes for a problem or it can be combined with a tree diagram

to categorise

possible solutions. Thus it can assist in problem solving. It

can be used to group customer requirements in a complex product and can help

one to design a product with characteristics and features that would satisfy

and delight customers. It can be used to categorise actions in an

implementation plan leading to a rationalised distribution of responsibility.

In fact the tool can

be used to break up any complex problem or task into smaller

more easily manageable bits. Someone has asked a question - ŌĆ£How

do you eat a whale ?ŌĆØ which has an obvious answer -ŌĆØA

mouthful at a timeŌĆØ. Another similar set of a question

and an answer is - ŌĆ£How to eat an elephant -

slice by sliceŌĆØ.

Well

affinity diagram is a tool that helps to break up a whale into convenient

mouthfuls or an elephant into manageable slices. Its simplicity makes it a very

widely applicable tool.

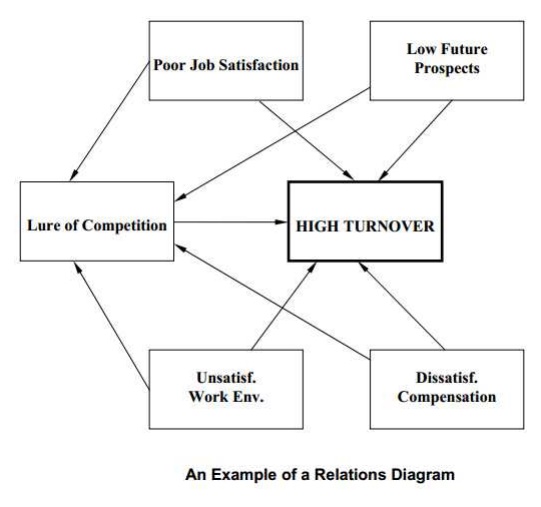

Relations Diagram Purpose

The purpose of relations diagram

is to generate a visual representation of the relations between an effect and

its causes as well as the interrelationship between the causes in complex

problems.

Structure

As mentioned in the opening paragraph of the chapter, the

structure of relations diagram is not very rigid; it is quite flexible. Only thing

fixed about the diagram is a bold bordered rectangle in which the ŌĆśeffectŌĆÖ

is written. The causes are entered in light rectangles and lines are drawn to

show relation

between

the rectangles. The lines have arrows at one end showing which is the cause and

which is the effect - the arrow always leading from the cause to the effect.

The most common shape the diagram takes has the ŌĆśeffectŌĆÖ

at the centre, with immediate causes surrounding it and secondary and

tertiary causes as outer layers.

Procedure

To

prepare a relations diagram, there is a need for a large number of causes. No

single individual can generate an exhaustive list of causes.

Hence the tool gives best results when it is used in a group.

The group must brainstorm the subject to

get the maximum number of causes.

The steps

in the preparation of a relations diagram are:

1.

Decide the ŌĆśeffectŌĆÖ or the problem for which causes are to be found.

Write is

in the centre of the flip chart or a board and enclose it in a dark bordered

rectangle.

Discuss

the subject and confirm the ŌĆśeffectŌĆÖ.

2. Brainstorm

to identify the immediate causes for the effect first. Enter these in

rectangles around the central dark rectangle.

Take care to place causes likely to be related to one another

in adjacent positions.

It is quite possible that the locations of the causes may have

to be changed as one progresses.

Hence a white board is preferable to a flip chart for this

exercise. If a flip chart is used, the causes may be written on post-it pads

and stuck on the chart so that their location can be changed easily.

3. Connect

these immediate causes to the effect by connecting the rectangles of the causes

to that of the effect with a line with an arrow pointing towards the effect.

Explore the cause and effect relationship among the immediate causes and

connect them, keeping in mind that

the arrow always points to an effect.

4. Taking

each of these immediate causes as an effect, brainstorm to find causes for them

one by one.

The key question for identifying causes is ŌĆ£why ?ŌĆØ.

Keep asking the question till the root causes are

identified

for the immediate, secondary and tertiary causes.

5. Explore

the relationship between all the causes and connect the rectangles as in

step-3. Show as many relations among different causes as possible. A large

number of routes leading to the same root causes provides an indication that

the root cause may be an important contributor to the problem.

6. Brainstorm

to find the more important root causes and more prominent links leading to the

effect. Mark these by making the rectangles and the connecting lines darker.

7. If

necessary, rearrange the rectangles in such a way that the connecting lines are

short and the diagram compact.

9. Provide a suitable title to the diagram.

Applications

Relations diagram can be applied to explore cause and effect

relationships, especially in complex situations where the causes are likely to

be mutually related. The most common use is in problem solving to identify

multiple interrelated causes. The output of the tool is a list of root causes

for the problem with some indication of their relative importance. The output

has to be considered as only an indication of the relative importance of the

causes. Data has to be collected to confirm or reject the conclusions arrived

at the end of the session. Priority of corrective actions to eliminate the

causes should be based on the data collected, not on output of relations

diagram. The output of relations diagram is based on the perception of the

members of the group brainstorming the issue; it needs to be supported by

facts. While the output is important as it points a direction to data

collection efforts, it is no substitute for facts and data.

Relations

diagram

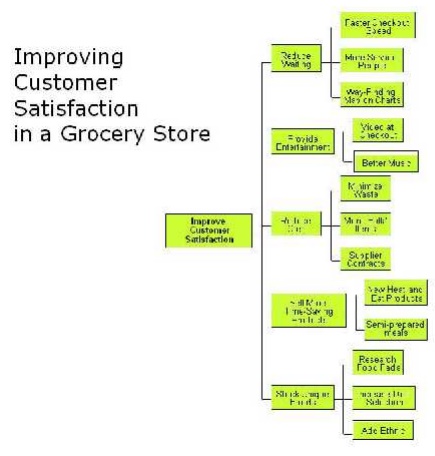

Tree

Diagram

Purpose

The purpose of the tree diagram

is to explore ways and means to achieve an objective, develop a list of

alternate means to reach the desired situation in a sequential order and to

present them in a visual form.

Procedure

This tool like other tools in the

ŌĆśnew sevenŌĆÖ is a group tool. A brainstorming session is necessary to collect

a large number of ideas for the means to achieve the objective. The rules of

brainstorming should be observed to get the best results from the tool.

The steps in the procedure to develop a tree diagram are :

Identify

a high priority problem that needs to be solved at the earliest. Prepare an

objective statement describing the desired situation or the target solution.

2. Decide

the appropriate form of the diagram - cascade or tree as well as direction of

flow after a brief discussion. Place the target solution in the dark rectangle.

3. Brainstorm

to identify the primary means to achieve the objective. Arrange them in an

appropriate order keeping in mind the likely interrelations between them and

place them in rectangles at the first level.

4. For each

of the primary means, identify secondary means which would be necessary to

attain those means. Arrange them in next level boxes.

5. Identify

tertiary means required to attain each of the secondary means and place them in

a proper order in the next level boxes.

6. Continue

the process till the group feels that the end of the line has been reached.

7. If a

lower level means is required to attain two higher level means, it may be

connected to both. Rearrange the boxes if necessary to make this possible. Use

of POST-IT pads can make such a rearrangement simple.

8. Brainstorm

to reach a consensus on the relative importance of the last level means to

priorities action.

9. Give a

suitable title to the diagram. Application The most important application of

the tree diagram is for devising solutions for problems. It helps one to

develop a systematic step by step strategy to achieve an objective. It is also

useful in monitoring the implementation of solutions by taking care of

accomplishment of means at different levels.

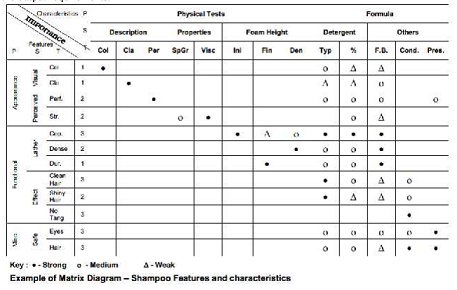

Matrix

Diagram

Purpose

The purpose of a matrix diagram is to explore the existence

and the extent of relations between individual items in two sets of factors or

features or characteristics and express them in a symbolic form that is easy to

understand. The purpose for which the tool is most frequently used is to

understand the relation between customer expectations as expressed by the

customers and product characteristics as designed, manufactured and tested by

the manufacturer.

Procedure

The steps

in the procedure to prepare a matrix diagram are :

1. Decide the two sets of factors for which relations are

required to be clarified. Call the set of the main factors

ŌĆśfeaturesŌĆÖ and the set of factors dependent on it counterpart ŌĆścharacteristicsŌĆÖ

or

characteristics.

2. Divide

the features into primary, secondary and tertiary features.

3. Divide

the characteristics into primary, secondary and tertiary characteristics.

4. Place the

features vertically on the left hand side of the matrix and characteristics

horizontally on top of the matrix.

5. Enter the

importance of the features on the column after that for the tertiary features.

6. In the

main body of the matrix, place symbols at the squares denoting the relationship

between thefeature and the characteristic meeting at the intersection. The

symbols to be used are :

- Strong relationship - Medium relationship - Weak

relationship

In case there is no relation between the concerned feature and

characteristic, leave the square blank to indicate ŌĆśno relationŌĆÖ.

The relationship should be based on data available with the team or on the

results

of a brainstorming session which must be confirmed by collecting necessary

data.

7. Title the diagram suitably. ApplicationsMatrix diagram,

being a very simple table showing relations between individual items in two

sets of factors, can be put to a wide variety of uses.

The symbolic representation of the relationship makes the

diagram so much easier to understand as compared to a table with a lot of

figures. Let us see some of the possible applications of a matrix diagram.

Matrix diagram can be used to solve problems by arranging data

in such a way that the relations between relevant factors are brought into

sharp focus. It can be used to understand relations between

customer satisfaction and product characteristics, between

complaints and product groups, between complaints and

geographical regions, between a productŌĆÖs performance in the market and

promotional inputs on it and so on. Once the relations between

individual items in sets of factors are clearly understood and agreed upon, it

becomes easy to solve problems and to plan and implement solutions

systematically.

There is no limit to the use of the tool. The unlimited

possibility of the application of the tool is proved by a couple of unusual

examples. A book on

QC tools written by Japanese authors gives an example where

the tool was used to describe the relations between male and female members of

the staff in an office. A recent article in a magazine brought out by an NBFC

(Non Banking Finance Company) for the benefit of investors used the matrix

diagram to depict the vulnerability of different industries. The diagram

provides relation between 24 industries from Aluminium and Automobiles to tyres

and yarn with half a dozen parameters such as over-capacity, demand recession,

cheap imports etc. The matrix had symbols indicating high, moderate, slight or

no vulnerability of the industry on that parameter. The only difference is that

the symbols used were not the same as those conventionally used in a matrix

diagram. The most important application of matrix diagram is in clarifying

relations

between individual features of

customer requirements and individual product characteristics. Thus the tool

enables one to translate customer expectations into technical specifications

accurately. In other words it helps one develop a product specification that

will satisfy customer expectations. Its use can be extended to clarify the

relationship between product characteristics on one side and product

formulation and process parameters on the other side. In other words it can be

used to generate a process specification that would ensure compliance to the

requirements of a product specification. It can be used to develop

specification requirements for inputs to a process by studying their relation

to the output requirements.

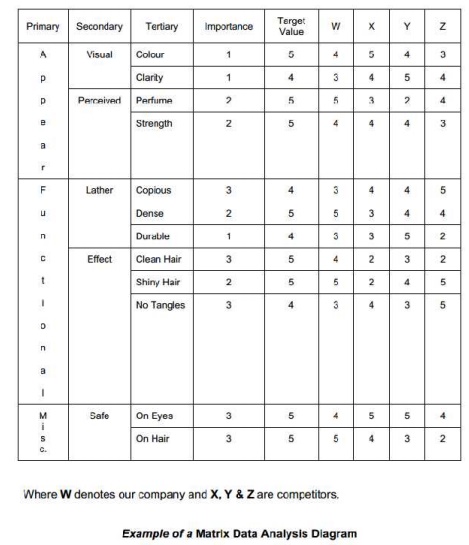

Matrix

Data Analysis Diagram

Purpose

The purpose of matrix data analysis diagram is to present

numerical data about two sets of factors in a matrix form and analyse it to get

numerical output. The factors most often are products and product

characteristics. The purpose then is to analyse the data on several

characteristics for a number of products and use the information to arrive at

optimum values for the characteristics for a new product or to decide the

strong points of a product and use the information for designing a strategy for

the promotion of the product.

Procedure

The procedure

for creating a matrix data analysis diagram consists of the following steps:

1. Decide

the two factors whose relations are to be analyses.

2. Check the

number of individual items in the two factors.

3.

Prepare a matrix to accommodate all the items of the two factors.

4. Enter

numerical data in the matrix.

5. Give the

diagram a suitable title. Applications

The most common application of matrix data analysis diagram is

to decide the desired product characteristics of a new product based on the

analysis of product characteristics of similar products in the market and the

intended positioning of the new product. For instance the characteristics of a

toilet soap for customers with normal skin would be somewhere in between those

for a soap for dry skin and a soap for oily skin. A cosmetic product for

growing children would have characteristics between those of a baby cosmetic

and an adult cosmetic. By collecting data on the product characteristics of

related products and placing them in a matrix data analysis diagram, one can

decide the desired characteristics of the proposed product depending on target

group of customers for the new product.

Analysis of the data can also be used to identify the

strongest characteristics of an existing product to decide its promotional

inputs. The tool can also be used to study the causes of customer complaints.

It can also be used to determine process parameters to achieve desired product

characteristics.

The tool can be very useful in

compiling data obtained on the analysis of competitive products with a view to

develop a product better than the competition or to devise a marketing strategy

for the product based on its strengths.

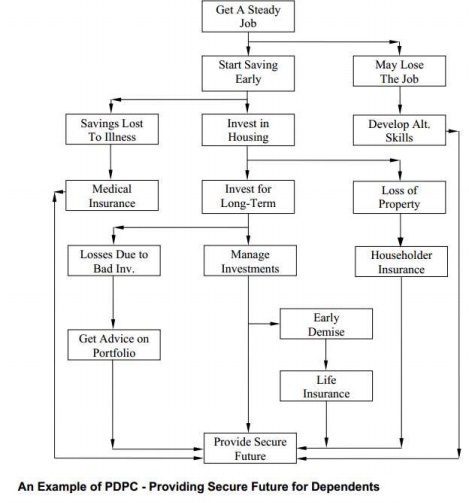

Process Decision Programme Chart

Purpose

The purpose of process decision programme chart is to prepare

for abnormal occurrences with low probability which may otherwise be overlooked

and to present the occurrences as well as the necessary countermeasures to

guard against such occurrences in the form of a visual chart. The tool forces one

to

think of the possible obstacles in the smooth progress of a

process or a project and then find ways and means to surmount those obstacles

to ensure the successful and timely completion of the process or the project.

Thus the tool helps one to prepare a contingency plan to achieve the objective

if

adverse

events occur.

Procedure

The steps

in the preparation of a process decision programme chart are :

1. Prepare

a ŌĆśnormalŌĆÖ flowchart of the process with all expected events as steps in the

chart.

2. Consider

the possibility of the process not going as per the plan due to any abnormal,

though less probable, occurrences.

3. Show

these occurrences on the flowchart through branching at appropriate locations.

4. Consider

how the abnormal occurrence will affect the process and search for ways and

means to counter the effect.

5. Show

these countermeasures in rectangles connecting the corresponding abnormal

occurrence on one side and the process objective or the goal on the other.

6. Give a

suitable title to the diagram.

Steps 2 and 4 require totally different type of thinking and

hence the team must be prepared to think on appropriate lines.

One needs to put on different ŌĆśthinking hatsŌĆÖ while brainstorming steps 2 and 4

and the facilitator must inform all members about it. As

suggested by Dr. Edward De Bono in his book ŌĆśSix Thinking

HatsŌĆÖ the correct thinking hats for steps 2 and 4 are black and yellow which

respectively encourage ŌĆśnegative logicalŌĆÖ and ŌĆśpositive logicalŌĆÖ thinking.

Applications

The tool has the widest range of

applications as it can be used for a range of activities from simple ones like

a game of bridge or reaching railway station or airport in time to catch a

train or a plane to complex processes or projects. In fact if can be applied to

all processes to ensure their success by systematically minimising the untoward

effect of unexpected adverse occurrences. Through the process of brainstorming

for possible adverse occurrences and for measures to counter them, one assures

the success of the process even if such events do occur. The tool can be used

to prevent problems by identifying opportunities for error and devising

measures to avoid failure. It can be used during the implementation of

solutions for predicting resistance and for planning measures to overcome the

resistance.

Process decision programme chart

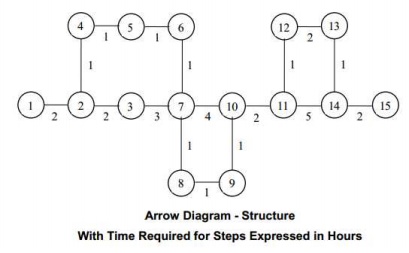

Arrow Diagram

Purpose

The purpose of an arrow diagram

is to create a visual presentation of the steps of a process or tasks necessary

to complete a project with special emphasis on the time taken for these

activities. The diagram provides a clear understanding of the schedule of

various steps in the process which helps one to monitor the process for

ensuring its completion on time.

Procedure

The steps for preparing an arrow

diagram are :

1. List all

tasks or activities that need to be accomplished before the completion of the

process or the project.

2. Decide

which steps are undertaken in series and which steps can be run in parallel.

3. Arrange

the activities in a proper sequence.

4.

Prepare ŌĆśEvent NodesŌĆÖ at the completion

of steps and number them. Where the process is

bifurcating into two or more parallel streams, more lines will

flow from a node and where the parallel streams are merging, two or more steps

will lead to a node.

5. Write the

description of the step on top of the line or to the left of the line. Decide

the time required for completing each step and write it under or to the right

of the line.

6. Calculate

the earliest time to reach an event node for the start of the process. Where

more than one streams are combining, the maximum time taken by a stream is

taken into consideration. This time is entered on the top half of the

rectangle. This time is related to the starting time of the process which is

taken as zero.

7. After the

time for all event nodes including the completion of the process or the project

is available, one calculates the latest time by which an event node must be

reached. This is done by starting at the time of completion and going back step

by step. The time is entered on the bottom half of the rectangle. The time

indication at all event nodes will appear as :

X Y where X is the earliest time by which the event can be

completed and Y is the latest time by which the event should be completed.

Give a title to the diagram. As

the calculation of the time indications is extremely important in the

construction of an arrow diagram it is necessary that we understand the

procedure well. Let us understand the concept through diagram.

Let us calculate the time the events can be reached earliest

by adding time for the step to the time of the earlier event starting with zero

time at the start i.e. event-1. Where there are two streams one has to take the

time for the longer or the critical path. The time to be put on the top half of

the rectangle for the 15 event nodes are given in table 3.

For event node 7, we get two

values. As the time for node 6 is 5 hours and step from 6 to 7 takes one hour,

the time for 7 would be 6 hours. But time for node 3 is 4 hours and the step

from 3 to 7 takes 3 hours, the time for node 7 comes to 7 hours. The earliest

both streams get ready is 7 hours and hence one has to take 7 hours as the time

for node 7. The same principle has been applied for calculating the time for nodes

10 and 14.

Now let us see how to calculate

the time to be put on the bottom half of the rectangle or the time by which the

event must be reached to ensure

1 2 3 7 10 11 14 15

8 9

1 1 2

1 1 1 1

2 2 3 4 2 5 2

1 11completion of the project on

time. In this case one has to start with event 15 as 20 hours and calculate the

time for the event by reducing the time taken for the step. Step from event 14

to 15 takes 2 hours. To complete the project at 20 hours, it is essential that

one reaches event 14 by 18 hours. In this way

we get the time by which the

events must be accomplished. These are given in table 4. Applications

The most common application of an

arrow diagram is in planning and scheduling projects which involve a large

number of activities. The diagram is also useful in planning and scheduling

steps in complicated processes. Once an arrow diagram is ready with time

indications for all stages of the project or the process, referred as the event

nodes in the procedure, one can look for

opportunities to reduce the time

taken for the project by concentrating on the steps on the critical path. It

can then be used to monitor the progress of the project throughout its

duration.

Related Topics