Chapter: Mechanical : Total Quality Management (TQM) : TQM Tools & Techniques

Six Sigma

SIX SIGMA

Prerequisite Discussion

Six Sigma is a set of techniques and

tools for process improvement. It was developed by Motorola in 1986, coinciding

with the Japanese asset price bubble which is reflected in its terminology.

Six Sigma seeks to improve the

quality of process outputs by identifying and removing the causes of defects

(errors) and minimizing variability in manufacturing and business processes. It

uses a set of quality management methods, including statistical methods, and

creates a special infrastructure of people within the organization

("Champions", "Black Belts", "Green Belts",

"Yellow Belts", etc.) who are experts in these methods.

WHAT IS SIX SIGMA?

┬Ę

Six sigma stands for six standard

deviation from mean (sigma is the Greek letter used to represent

standard deviation in statistics).

┬Ę

Six sigma, similar to Zero Defect (ZD), is a

philosophical benchmark or standard of excellence proposed by Philip Crosby.

┬Ę

Six sigma methodology provides the techniques and

tools to improve the capability and reduce the defects in any process.

┬Ę

It was started by Motorola in 1987, in its

manufacturing division.

┬Ę

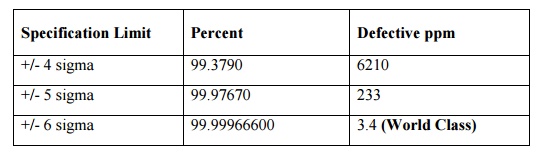

Six sigma strives for perfection. It allows for

only 3.4 defects per million opportunities (or 99.999666 percent

accuracy). Here a defect can be anything from a faulty party to an incorrect

customer bill.

┬Ę

Six sigma improves the process performance,

decrease variation and maintains consistent quality of the

process output. This leads to defect reduction and improvements in profits, product

quality and customer satisfaction.

┬Ę

Six sigma incorporates the basic principles and

techniques used in business, statistics and engineering.

The objective of six sigma

principle is to achieve zero defects products/process. It allows 3.4 defects

per million opportunities.

WHY DO WE NEED SIX SIGMA?

(Three sigma quality is not enough. Why?)

We know that, the three sigma

quality, i.e., the natural variability (x ┬▒ 3s) is equal

to tolerance (= upper specification limit ŌĆō lower

specification limit). It means, in normal distribution curve, only 0.27% of the

output would be expected to fall outside the specifications limits.

![]()

The real meaning of 3s concept: A medium aircraft consists of

10,000 different parts. At 3s quality,

27 of those parts in an assembled aircraft would be defective. So three sigma

quality level cannot be accepted as good enough quality level. So we have to

increase the sigma level (i.e.,

reducing the number of

defectives). In fact, even four sigma quality also not sufficient for the

aircraft case. ThatŌĆÖs why six sigma quality level is

preferred than 3Žā and 4Žā quality levels.

CONCEPT

Six Sigma ŌĆō A vision of quality which equates with only 3.4 defects per million opportunities for each product or service transaction. Strives for perfection.

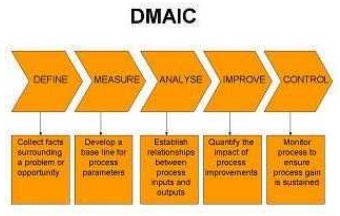

DMAIC methodology provides a structured framework for solving business problems by assuring correct and effective process execution.

This methodology has 6 phases in which, in the case of Six Sigma, teams take total employee involvement approaches to complete the cycle of process management and use self-diagnosis skills to fulfill the goals of each phase.

DMAIC

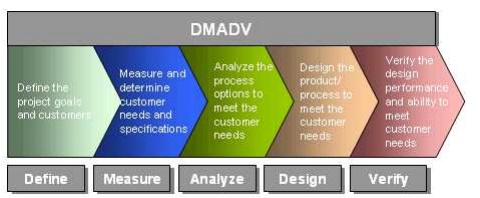

DMADV

DMAIC ŌĆō It is

used for improving existing processes/products.

DMADV ŌĆō It is

applied to a new processes/products.

Example: (Need for Six Sigma)

ŌĆó Aircraft consist 10000 different parts.

ŌĆó At 3 sigma level27 parts will be defective.

ŌĆó It cannot afford to fail 27 parts in million at 3 sigma level.

ŌĆó Similarly 1). Failure in surgery. 2). Testing of nuclear plant.

ŌĆó Therefore increased to six sigma level. (reduce the number of defects)

Significance:

Each Six Sigma project carried out within an organization follows a defined sequence of steps and has quantified value targets, for example: reduce process cycle time, reduce pollution, reduce costs, increase customer satisfaction, and increase profits.

Companies

which have adopted six sigma:

┬Ę

Motorola

┬Ę

Sony

┬Ę

IBM

┬Ę

Honda

┬Ę

Texas Instruments

┬Ę

Hitachi

┬Ę

Polaroid

┬Ę

Canon

Glossary

:

DMAIC ŌĆō It is

used for improving existing processes/products.

DMADV ŌĆō It is

applied to a new processes/products.

Related Topics