Chapter: Mechanical : Total Quality Management (TQM) : TQM Tools & Techniques

Benchmarking

BENCHMARKING

CONCEPT:

├ś Benchmarking

is a systematic method by which organizations can measure themselves against

the best industry practices.

├ś Benchmarking

is a systematic search for the best practices, innovative ideas, and highly

effective operating procedures.

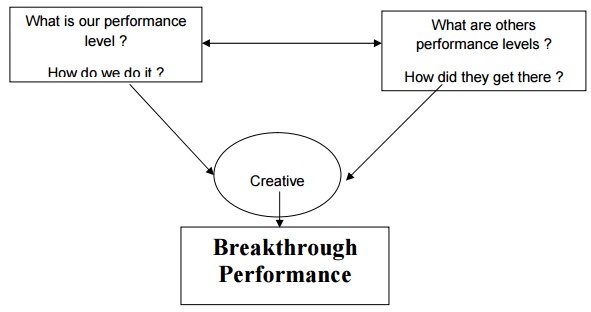

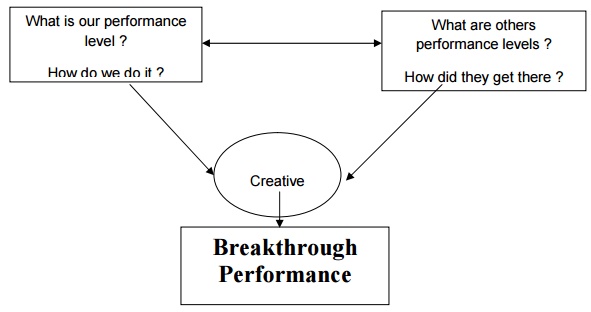

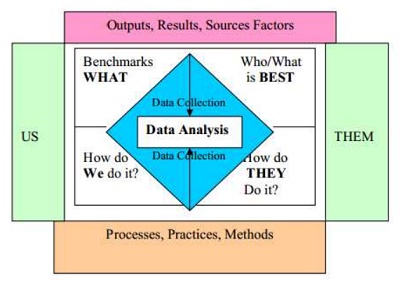

BENCHMARKING CONCEPT

REASONS

TO BENCHMARK :

├ś It is a

tool to achieve business and competitive objectives.

├ś It can

inspire managers (and Organizations) to compete.

├ś It is

time and cost effective.

├ś It

constantly scans the external environment to improve the process.

├ś Potential

and useful technological breakthroughs can be located and adopted early.

PROCESS

OF BENCHMARKING

The

following six steps contain the core techniques of Benchmarking.

1Decide

what to benchmark

├ś Benchmarking

can be applied to any business or production process.

├ś The

strategy is usually expressed in terms of mission and vision statements.

├ś Best to

begin with the mission and critical factors.

├ś Choosing

the scope of the Benchmarking study.

├ś Pareto

analysis ŌĆō what process to investigate.

├ś Cause and

Effect diagram ŌĆō for tracing outputs back.

2Understand current performance

├ś Understand

and document the current process.

├ś Those

working in the process are the most capable of identifying and correcting

problems.

├ś While

documenting, it is important to quantify.

├ś Care

should be taken during accounting information.

3Plan

├ś A

benchmarking team should be chosen.

├ś Organizations

to serve as the benchmark need to be identified.

├ś Time

frame should be agreed upon for each of the benchmarking tasks.

4Types of

benchmarking

┬Ę

Internal

┬Ę

Competitive

┬Ę

Process

5Study

Others

Benchmarking

studies look for two types of information

├ś How best

the processes are practiced

├ś Measurable

results of these practices Three techniques for conducting the research are

├ś Questionnaires

├ś Site

visits

├ś Focus

groups

6Learn

from the data

Answering

a series of questions like

├ś Is there

a gap between the organizationŌĆÖs performance and the

performance of the best-in-class organizations?

├ś What is

the gap? How much is it?

├ś Why is

there a gap? What does the best-in-class do differently that is better?

├ś If

best-in-class practices were adopted, what would be the resulting improvement?

Benchmarking

studies can reveal three different outcomes

├ś Negative

gap

├ś Parity

├ś Positive

gap

7Using the findings

The objective is to close the gap. For this

├ś Findings

must be communicated to the people within the organization

├ś Action

plans must be developed to implement new processes

Groups

that must agree on the change

├ś Process

owners

├ś Upper

management

Steps for

the development and execution of action plans are

1.

Specify tasks

2.

Sequence tasks

3.

Determine resources needs

4.

Establish task schedule

5.

Assign responsibility for each task

6.

Describe expected results

7.

Specify methods for monitoring results

PITFALLS

AND CRITICISMS OF BENCHMARKING :

├ś Idea of

copying others

├ś It is not

a cure or a business philosophy

├ś Some

process have to be benchmarked repeatedly

├ś It is not

a substitute for innovation.

SIGNIFICANCE:

├ś ŌĆó

Benchmarking is a systematic method by which organizations can measure

themselves

├ś against

the best Industry practices

├ś ŌĆó

It promotes superior performance by providing an organized framework

through which

├ś organization

learn how the ŌĆ£ best in classŌĆØ do things.

├ś ŌĆó

It helps for continuous improvement.

├ś ŌĆó

Benchmarking inspire managers (and organization) to compete.

├ś ŌĆó

Through Benchmark process organization can borrow ideas, adopt and refine them

to

├ś gain

competitive advantages.

Application:

Now a days, more than 60% companies in the world uses this

technique for fixing their target for continuous improvement. For them it is an

important tool. But to be effective it must be used properly. It breaks down

(waste money, time and energy and some times morale too) if process owners and

managers feel threatened or do not accept and act on the findings. Finally,

benchmarking is not a substitute for innovation; however, it is a source of

ideas from outsidethe organization.

These 4 questions formed the

basis on which Boeing, Digital equipments company, Motorola and Xerox jointly

developed a benchmarking template.

Related Topics