Chapter: Mechanical : Total Quality Management (TQM) : TQM Tools & Techniques

Benchmarking process

Benchmarking process

The

benchmarking process consists of following phases:

1. Planning.

The

essential steps are those of any plan development: what, who and how. What is

to be benchmarked?‖ Every function of an organization has or delivers a product or output. Benchmarking is

appropriate for any output of a process or function, whether it‗s a physical

good, an order, a shipment, an invoice, a service or a report.

To

whom or what will we compare? Business-to-business, direct competitors are

certainly prime candidates to benchmark. But they are not the only targets.

Benchmarking must be conducted against the best companies and business

functions regardless of where they exist.

How

will the data be collected? There‗s no one way to conduct benchmarking

investigations. There‗s an infinite variety of ways to obtain required data –

and most of the data you‗ll need are

readily

and publicly available. Recognize that benchmarking is a process not only of

deriving quantifiable goals and targets, but more importantly, it‗s the process

of investigating and documenting

the

best industry practices, which can help you achieve goals and targets.

2. Analysis.

The

analysis phase must involve a careful understanding of your current process and

practices, as well as those of the organizations being benchmarked. What is

desired is an understanding of internal performance on which to assess

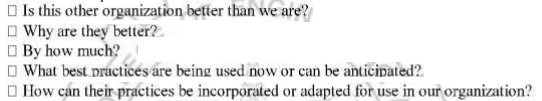

strengths and weaknesses. Ask:

Answers

to these questions will define the dimensions of any performance gap: negative,

positive or parity. The gap provides an objective basis on which to act—to

close the gap or capitalize on any advantage your organization has.

3.

Integration.

Integration

is the process of using benchmark findings to set operational targets for

change. It involves careful planning to incorporate new practices in the

operation and to ensure benchmark findings are incorporated in all formal

planning processes.

Steps

include:

Gain

operational and management acceptance of benchmark findings. Clearly and

convincingly demonstrate findings as correct and based on substantive data.

Develop

action plans.

Communicate

findings to all organizational levels to obtain support, commitment and

ownership.

4. Action.

Convert

benchmark findings, and operational principles based on them, to specific

actions to be taken. Put in place a periodic measurement and assessment of

achievement. Use the creative talents of the people who actually perform work

tasks to determine how the findings can be incorporated into the work

processes. Any plan for change also should contain milestones for updating the

benchmark findings, and an ongoing reporting mechanism. Progress toward

benchmark findings must be reported to all employees. 5. Maturity. Maturity

will be reached when best industry practices are incorporated in all business

processes, thus ensuring superiority. Tests for superiority:

Related Topics