Chapter: Mechanical : Total Quality Management (TQM) : TQM Tools & Techniques

The seven traditional tools of quality

The seven traditional tools of quality

I - Pareto chart: Italian

economist Vilfredo Pareto Shows on a bar graph which factors are

more significant. This method helps to find the vital few contributing maximum

impact.

Purpose: The

purpose of the Pareto chart is to prioritize problems No company has

enough resources to tackle every problem, so they must prioritize.

Pareto Principle: The

Pareto concept was developed by the describing the frequency

distribution of any given characteristic of a population. Also called the 20-80

rule, he determined that a small percentage of any given group (20%) account

for a high amount of a certain characteristic (80%).

Conclusion: The most

important thing in improving quality is to start somewhere, doing

something. As you begin using the Pareto chart to decide where your problems

are, you will discover many things about your processes and will come because

you will know where to improve.

II - Flowchart: A

technique that separates data gathered from a variety of sources so that patterns

can be seen (some lists replace "stratification" with or "run

chart").

Purpose: Flow

Charts provide a visual illustration of the sequence of operations required to

complete a task.

A picture of the steps the

process undergoes to complete it's task. Every process will require input(s) to

complete it's task, and will provide output(s) when the task is completed. Flow

charts can be drawn in many styles. Flow charts can be used to describe a

single process, parts of a process, or a set of processes. There is no right or

wrong way to draw a flow chart. The true test of a flow chart is how well those

who create and use it can understand it. Input ---------------------Process----------------Output

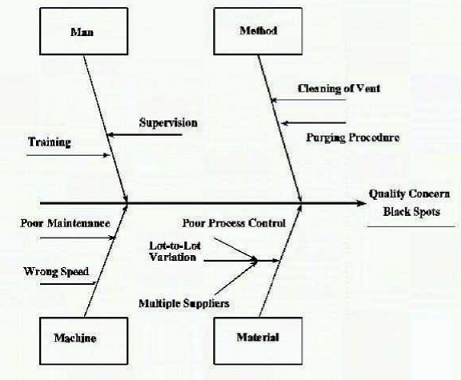

III - Cause-and-Effect

Diagrams - 1943 by Mr. Kaoru Ishikawa at the University of

Tokyo

Purpose: One important part of process

improvement is continuously striving to obtain more information about

the process and it's output. Cause-and-effect diagrams allow us to do not just

that, but also can lead us to the root cause, or causes, of problems.

Constructing the Cause-and-Effect Diagram:

Step 1: Select the team members

and a leader. Team members knowledgeable about the quality. Team members focus

on the problem under investigation.

Step 2: Write the problem

statement on the right hand side of the page, and draw a box around it with an

arrow running to it. This quality concern is now the effect.

Step 3: Brain-storming. The team

members generate ideas as to what is causing the effect.

Step 4: This step could be

combined with step 3. Identify, for each main cause, its related sub-causes

that might affect our quality concern or problem (our Effect). Always check to

see if all the factors contributing to the problem have been identified. Start

by asking why the problem exists.

Step 5: Focus on one or two

causes for which an improvement action(s) can be developed using other quality

tools such as Pareto charts, check sheets, and other gathering and analysis

tools. Conclusion: Improvement requires knowledge. The more information

we have about our processes the better we are at improving them.

Cause-and-effect diagrams are one quality tool that is simple yet very powerful

in helping us better understand our processes.

IV - Check Sheet

Purpose: Check

sheets allow the user to collect data from a process in an easy, systematic,

and organized manner.

Data Collection: Before we

can talk about check sheets we need to understand what we mean by data

collection. This collected data needs to be accurate and relevant to the

quality problem. The first is to establish a purpose for collecting this data.

Second, we need to define the type of data that is going to be collected.

Measurable data such as length, size, weight, time,...etc., and countable data

such as the number of defects. The third step is to determine who is going to

collect that data and when it should be collected.

V-

Histograms

Purpose: To

determine the spread or variation of a set of data points in a graphical form.

It is always a desire to produce things that are equal to their design

values.

Histograms: A

histogram is a tool for summarizing, analyzing, and displaying data. It provides

the user with a graphical representation of the amount of variation found in a

set of data.

Constructing a Histogram: The

following are the steps followed in the construction of a histogram:

Data collection: To ensure good

results, a minimum of 50 data points, or samples, need to be collected

Calculate the range of the sample

data: The range is the difference between the largest and smallest data points.

Range = Largest point - smallest point.

Calculate the size of the class

interval. The class interval is the width of each class on the X axis. It is

calculated by the following formula:

Class interval = Range / Number of classes.

Calculate the number of data

points (frequency) that are in each class. A tally sheet is usually used to

find the frequency of data points in each interval.

Conclusion: Histogram

is simple tools that allow the user to identify and interpret the variation

found in a set of data points. It is important to remember that histograms do

not give solutions to problems.

VI - Scatter Diagrams

Purpose: To

identify correlations that might exist between a quality characteristic and a

factor that might be driving it.

Scatter Diagrams: A

scatter diagram is a nonmathematical or graphical approach for identifying

relationships between a performance measure and factors that might be driving

it. This graphical approach is quick, easy to communicate to others, and

generally easy to interpret.

Interpreting the Results: Once

all the data points have been plotted onto the scatter diagram, you are

ready to determine whether their exists a relation between the two selected

items or not. When a strong relationship is present, the change in one item

will automatically cause a change in the other. If no relationship can be

detected, the change in one item will not effect the other item. Their are

three basic types of relationships that can be detected to on a scatter

diagram: 1. Positive relationship 2. Negative relationship 3. No relationship

Conclusion: Scatter diagrams allow the

user to graphically identify correlations that could exist between a

quality characteristic and a factor that might be driving it. It is a quality

tool that is simple, easy to communicate to others, and generally easy to

interpret

VII - Control Charts

Purpose: Process is

in control and to monitor process variation on a continuous basis. Identifying

the tolerance level in the variations. Control charts is one SPC tool that

enables us to monitor and control process variation. Types of variation Common

and Special Cause Variation

Control charts: Developed

in the mid 1920's by Walter Shewhart of Bell labs. There are two basic

types of control charts, the average and range control charts. The first deals

with how close the process is to the nominal design value, while the range

chart indicates the amount of spread or variability around the nominal design

value. A control chart has basically three line: the upper control limit UCL,

the center line CL, and the lower control limit LCL. A minimum of 25 points is

required for a control chart to be accurate.

Related Topics