Chapter: Mechanical : Total Quality Management (TQM) : TQM Tools & Techniques

TaguchiŌĆÖs Quality Loss Function

TAGUCHIŌĆÖS QUALITY LOSS FUNCTION

TaguchiŌĆÖs Quality Loss Function concept combines cost, target and variation in one metric withspecifications being of secondary importance.

Taguchi has defined quality as the loss imparted to society from the time a product is shipped. Societal losses include failure to meet customer requirements, failure to meet ideal performance and harmful side effects.

├ś CUSTOMERS PERCEIVE QUALITY AS MEETING THE TARGET RATHER

THAN JUST MEETING THE SPECIFICATIONS.

There are three common quality loss functions

1. Nominal - the - best.

2. Smaller - the - better.

3. Larger - the ŌĆō better

NOMINAL ŌĆō THE ŌĆō BEST :

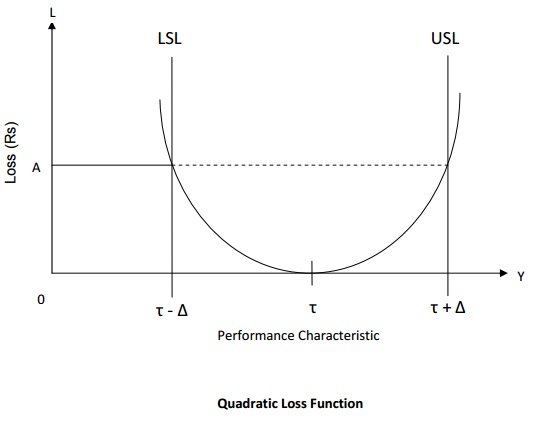

Although Taguchi developed so many loss functions, many situations are approximated by the quadratic function which is called the Nominal ŌĆō the ŌĆō best type.

Quadratic Los

The quadratic function is shown in figure. In this situation, the loss occurs as soon as the performance characteristic, y, departs from the target Žä.

At Žä, the loss is Rs. 0.

At LSL (or) USL, the loss is Rs. A.

The quadratic loss function is described by the equation L = k (y - Žä) 2. Where,

L = cost incurred as quality deviates from the target.

y = Performance characteristic

Žä = target

k = Quality loss coefficient.

The loss coefficient is determined by setting Ōłå = (y ŌĆō Žä), the deviation from the target. When Ōłå is the

USL (or) LSL, the loss to the customer of repairing (or) discarding the product is Rs. A.

Thus,

K = A / (y ŌĆō Žä)2 = A / Ōłå2 .

SMALLER ŌĆō THE ŌĆō BETTER :

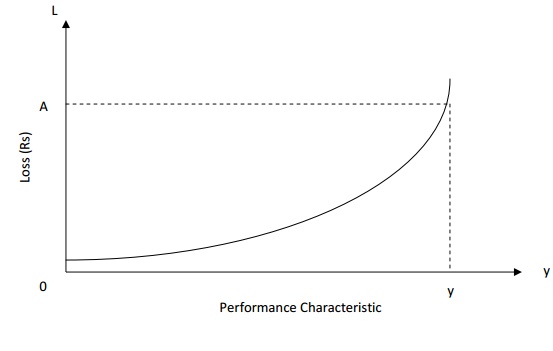

The following figure shows the smaller ŌĆō the ŌĆō better concepts.

The target value for smaller ŌĆō the ŌĆō better is 0. There are no negative values for the performance characteristic.

The radiation leakage from a microwave appliance, the response time for a computer, pollution from an automobile, out of round for a hole etc. are the performance characteristics for this concept.

LARGER ŌĆō THE ŌĆō BETTER :

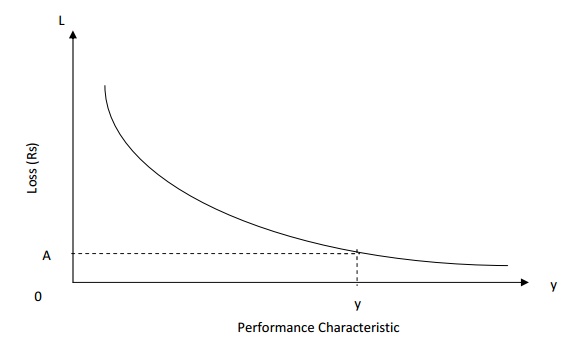

The following figure shows the concept of the Larger ŌĆō the ŌĆō better.

In the Larger ŌĆō the ŌĆō better concept, the target value is Ōł× (infinity), which gives a zero loss. There are no negative values and the worst case is at y = 0. Actually, larger ŌĆō the ŌĆō better is the reciprocal of smaller ŌĆō the ŌĆō better. The performance characteristics in Larger ŌĆō the ŌĆō better are bond strength of adhesives, welding strength etc.

Taguchi

quality loss function

Genichi Taguchi is a Japanese

quality expert, known for the Quality Loss Function and for methodologies to

optimise quality at the design stage ŌĆō ŌĆĢrobust

design. Taguchi received formal recognition for his work including

Deming Prizes and Awards. Genichi Taguchi considers quality loss all the way

through to the customer, including cost of scrap, rework, downtime,

warranty claims and ultimately reduced market share.

Genichi Taguchi's Quality Loss Function

The Quality Loss Function gives a

financial value for customers' increasing dissatisfaction as the

product performance goes below the desired target performance. Equally, it gives

a financial value for increasing costs as product performance goes

above the desired target

performance. Determining the target performance is an educated guess, often

based on customer surveys and feedback.

The quality loss function allows financial

decisions to be made at the design stage regarding the cost of

achieving the target performance.

Quality through Robust Design Methodology

Taguchi methods emphasised

quality

through robust design, not quality through inspection. Taguchi breaks the

design process into three stages:

1. System design - involves creating a working prototype

2. Parameter

design - involves experimenting to find which factors influence product

performance most

3. Tolerance

design - involves setting tight tolerance limits for the critical factors and

looser tolerance limits for less important factors.

TaguchiŌĆŚs

Robust Design methodologies allow the designer through experiments to

determine which factors most affect product performance and which

factors are unimportant.

The designer can focus on reducing

variation on the important or critical factors. Unimportant or uncontrollable

ŌĆĢnoise factors have negligible impact on the product performance and can be

ignored.

Robust Design of Cookies This is

easier explained by example. If your business makes cookies from raw

ingredients, there are many possible factors that could influence the quality

of

the cookie - amount

of flour, number of eggs, temperature of butter, heat of oven, cooking time,

baking tray material etc. With Genichi TaguchiŌĆŚs

Robust Design methodologies you would set up

experiments that would test a

range of combinations of factors - for example, high and low oven

temperature, with long and short cooking time, 1 or 2 eggs, etc. The cookies

resulting from each of these trials would be assessed for quality. A

statistical analysis of results would tell you which the most important factors

are, for example oven temperature affects cookie quality more than the number

of eggs. With this knowledge you would design a process that ensures the oven

maintains the optimal temperature and you would be able to consistently produce

good cookies.

Related Topics