Statistical Quality Control (SQC) | Applied Statistics - Process Control and Product Control | 12th Business Maths and Statistics : Chapter 9 : Applied Statistics

Chapter: 12th Business Maths and Statistics : Chapter 9 : Applied Statistics

Process Control and Product Control

Statistical Quality Control (SQC):

Process

Control and Product Control

The main objective in

any production process is to control and maintain a satisfactory quality level

of the manufactured product. This is done by ‘Process Control’. In Process

Control the proportion of defective items in the production process is to be

minimized and it is achieved through the technique of control charts. Product

Control means that controlling the quality of the product by critical

examination through sampling inspection plans. Product Control aims at a

certain quality level to be guaranteed to the customers. It attempts to ensure

that the product sold does not contain a large number of defective items. Thus

it is concerned with classification of raw materials, semi-finished goods or

finished goods into acceptable or rejectable products.

Control Charts

In an industry, there

are two kinds of problems to be faced, namely

(i) To check whether the

process is conforming to its standard level.

(ii) To improve the

standard level and reduce the variability.

Shewhart’s control

charts provide an answer to both. It is a simple technique used for detecting

patterns of variations in the data. Control charts are simple to construct and

easy to interpret. A typical control charts consists of the following three

lines.

(i) Centre Line (CL)

indicates the desired standard level of the process.

(ii) Upper Control Limit

(UCL) indicates the upper limit of tolerance.

(iii) Lower Control

Limit (LCL) indicates the lower limit of tolerance.

If the data points fall

within the control limits, then we can say that the process is in control,

instead if one or more data points fall outside the control limits, then we can

say that the process is out of control.

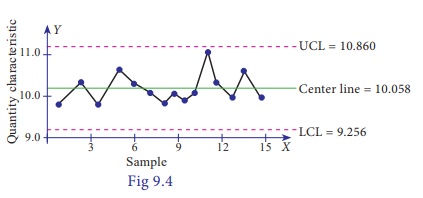

For example, the following lines with the data points plotted, diagram shows all the three controlsince all the points falls within the control limits, we can say that the process is in control.

Control Charts for Variables

These charts may be

applied to any quality characteristic that can be measured quantitatively. A

quality characteristic which can be expressed in terms of a numerical value is

called as a variable. Many quality characteristics such as dimensions like

length, width, temperature, tensile strength etc… of a product are measurable

and are expressed in a specific unit of measurements. The variables are of

continuous type and are regarded to follow normal probability law. For quality

control of such data, there are two types of control charts used. They are as

follows :

(i) Charts for

Mean ( ![]() )

)

(ii) Charts for Range

(R)

Related Topics