Problem Questions with Answer, Solution | Applied Statistics - Exercise 9.3: Statistical Quality Control (SQC) | 12th Business Maths and Statistics : Chapter 9 : Applied Statistics

Chapter: 12th Business Maths and Statistics : Chapter 9 : Applied Statistics

Exercise 9.3: Statistical Quality Control (SQC)

Exercise 9.3

1. Define Statistical Quality Control.

2. Mention the types of causes for

variation in a production process.

3. Define Chance Cause.

4. Define Assignable Cause.

5. What do you mean by product control?

6. What do you mean by process control?

7. Define a control chart.

8. Name the control charts for

variables.

9. Define mean chart.

10. Define R Chart.

11. What are the uses of statistical

quality control?

12. Write the control limits for the

mean chart.

13. Write the control limits for the R

chart.

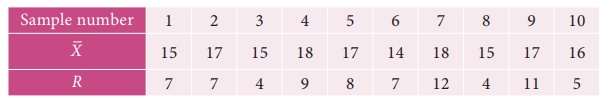

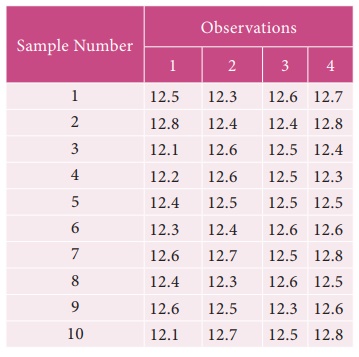

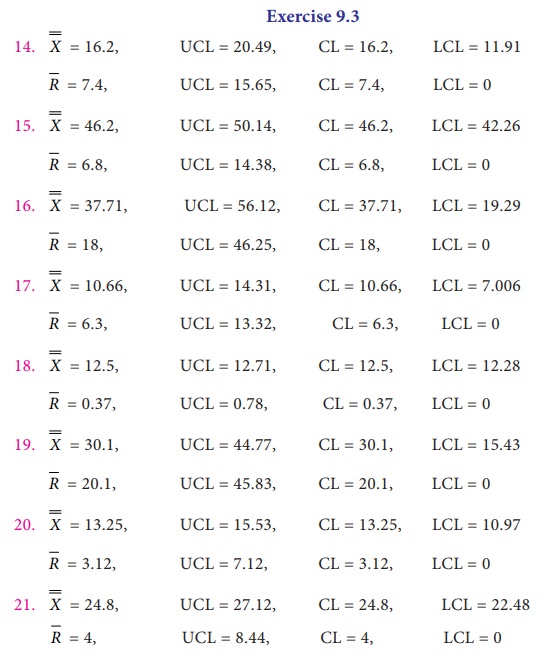

14. A machine is set to deliver packets

of a given weight. Ten samples of size five each were recorded. Below are given

relevant data:

Calculate the control limits for mean

chart and the range chart and then comment on the state of control. (conversion

factors for n = 5, A2 = 0.58 , D3 = 0 and D4 =

2.115 )

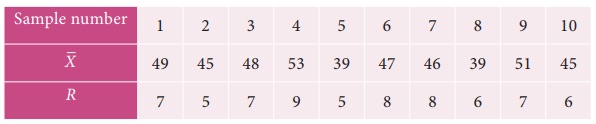

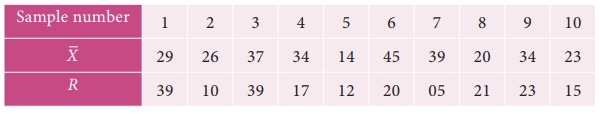

15. Ten samples each of size five are

drawn at regular intervals from a manufacturing process. The sample means ( ![]() ) and their ranges ( R ) are given below:

) and their ranges ( R ) are given below:

Calculate the control limits in respect

of ![]() chart. ( Given A2 = 0.58 , D3 = 0 and D4 = 2.115 )

chart. ( Given A2 = 0.58 , D3 = 0 and D4 = 2.115 )

Comment on the state of control.

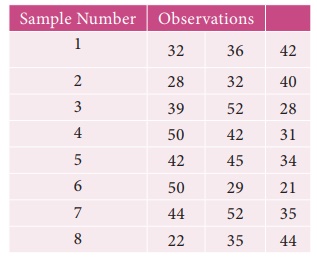

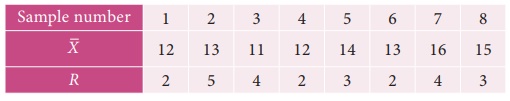

16. Construct ![]() and R charts

for the following data:

and R charts

for the following data:

(Given for n = 3, A2 = 0.58 ,

D3 = 0 and D4 = 2.115 )

17. The following data show the values

of sample mean ( ![]() ) and its range ( R ) for the samples of size five

each. Calculate the values for control limits for mean , range chart and

determine whether the process is in control.

) and its range ( R ) for the samples of size five

each. Calculate the values for control limits for mean , range chart and

determine whether the process is in control.

( conversion factors for n = 5, A2

= 0.58 , D3 = 0 and D4 = 2.115 )

18. A quality control inspector has

taken ten samples of size four packets each from a potato chips company.The

contents of the sample are given below, Calculate the control limits for mean

and range chart.

(Given for n = 5, A2 = 0.58 ,

D3 = 0 and D4 = 2.115 )

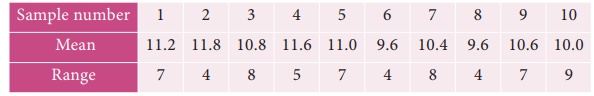

19. The following data show the values

of sample means and the ranges for ten samples of size 4 each. Construct the

control chart for mean and range chart and determine whether the process is in

control.

20. In a production process, eight

samples of size 4 are collected and their means and ranges are given below.

Construct mean chart and range chart with control limits.

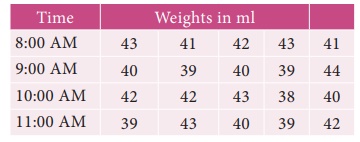

21. In a certain bottling industry the

quality control inspector recorded the weight of each of the 5 bottles selected

at random during each hour of four hours in the morning.

Answers:

Related Topics