Chapter: 11th 12th std standard Class Organic Inorganic Physical Chemistry Higher secondary school College Notes

Methods for the purification of liquids Distillation

Methods

for the purification of liquids Distillation

Distillation is used for separating the

constituents of a liquid mixture which differ in their boiling points.

Depending upon the difference in the boiling points of the constituents,

different types of distillation are employed. These are described below.

i) Simple

Distillation

Liquids with boiling points widely apart (about 40K and above) can be

purified by simple distillation if they do not decompose under ordinary

pressure. Simple distillation involves conversion of a liquid into its vapour

by heating in a distilling flask and then condensation of the vapour into a

liquid in the receiver.

Mixtures like the following can be separated by this simple

distillation.

a Nitro

benzene (b.p 484K) and benzene (b.p.354K)

b. Diethyl

ether (b.p.308K) and ethyl alcohol (b.p.351K)

Note : Simple distillation is also helpful in separating non-volatile

impurities from liquids.

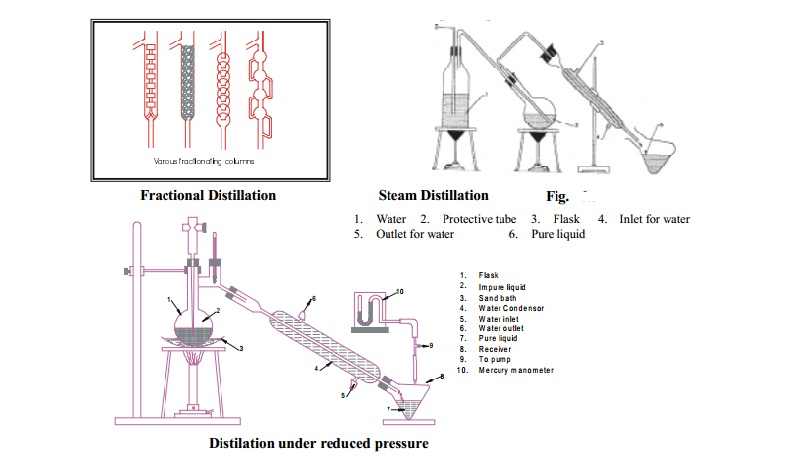

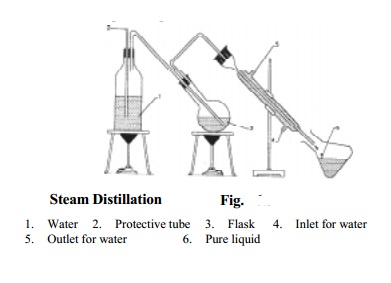

Fractional

Distillation

This method is applicable for the separation and

purification of a mixture of two or more miscible liquids whose boiling points

lie very close to each other.

This is similar to the ordinary distillation method with the only

exception that a fractionating column is introduced in-between the distillation

flask and the condenser.

The process of separation of the components in a liquid mixture at their

respective boiling points in the form of vapours and the subsequent

condensation of those vapours is called fractional distillation.

The

fractionating columns used for the purpose are of different shapes.

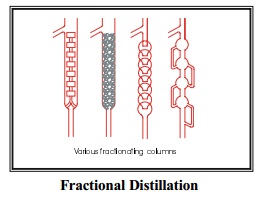

Steam Distillation

In steam

distillation impure compounds are distilled in a current of steam. This method

is applicable to solids as well as liquids. For purification by steam

distillation, an impure compound must satisfy the following conditions:

1.

It should not decompose at the steam

temperature.

2. It should have a fairly high vapour pressure at 373 K.

3. It should be insoluble in water.

4. The impurities present should be non-volatile

1. Water

2. Protective tube 3.

Flask4. Inlet for water

5. Outlet for water 6. Pure liquid

The apparatus used for steam distillation is shown in the figure (16.5).

The impure compound is taken in the round bottomed flask and a small quantity

of water is added. The flask is then heated gently. Now steam is bubbled

through the contents in the flask. The vapours of the compound mix up with

steam and escape into the condenser. The condensate thus obtained is a mixture

of water and the organic compound which can be separated.

Theory of

steam distillation

Let p1 represent the vapour pressure of water

and p2 the vapour pressure of the organic liquid. In steam distillation the

liquid boils at a temperature at which

p1 + p2 = Atmospheric Pressure

This temperature must be lower than the normal boiling point of water or

the organic liquid. The reason that p1 + p2 becomes equal to the atmospheric

pressure must earlier than p1 or p2 alone. Thus in steam distillation, the

impure liquid boils at a temperature which is lower than its normal boiling

point. Hence, steam distillation serves the same purpose as distillation under

reduced pressure. However, the former is cheaper but less useful than the

latter.

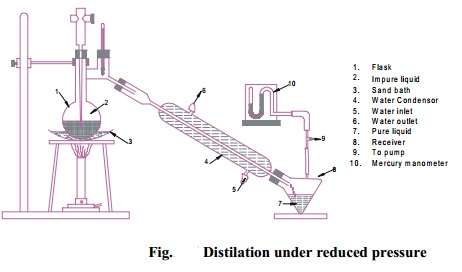

Distillation

under reduced pressure

This technique is used for purifying or

separating thermally unstable liquid compounds which decompose at their normal

boiling points.

Principle :

Lowering of pressure on the surface of a liquid lowers its boiling

point. As a result, a liquid can be boiled and distilled at a temperature much

below the normal boiling point without any decomposition.

Procedure :

Distillation under reduced pressure or vacuum is carried out in a

specially designed glass apparatus as shown in (Fig.).

The receiver is attached to a vacuum pump to reduce pressure. The

pressure is measured with the help of a manometer.

Advantages

of distillation under reduced pressure

Distillation under reduced pressure has the following advantages:

i)

The compounds which decompose on heating to

their boiling points under normal pressure can be purified by distillation

under reduced pressure. This is because at a reduced pressure, a liquid would

boil at temperature much below its normal boiling point.

In distillation under reduced pressure, a liquid boils at temperature

well below the normal boiling point. So, the distillation under reduced

pressure is more fuel-economical.

Extraction

with solvents

This method is based on the fact that organic substances are more

soluble in organic solvents than in water.

The organic substance is extracted from its

aqueous solution adopting the following procedure.

1.

The aqueous solution containing organic

substance is shaken with a suitable organic solvent which dissolves the

substance but is immiscible with water. Two layers are formed; the organic

layer and aqueous layer.

2.

The solvent layer containing the organic substance

(organic layer) is separated using a `separating funnel'. The impurities remain

in the aqueous layer removed by distillation to obtain the organic substance.

The organic solvent is removed by distillation to obtain the organic

substance.

Related Topics