Chapter: 11th 12th std standard Class Organic Inorganic Physical Chemistry Higher secondary school College Notes

Metallurgy - Purification of metals

Metallurgy - Purification of metals

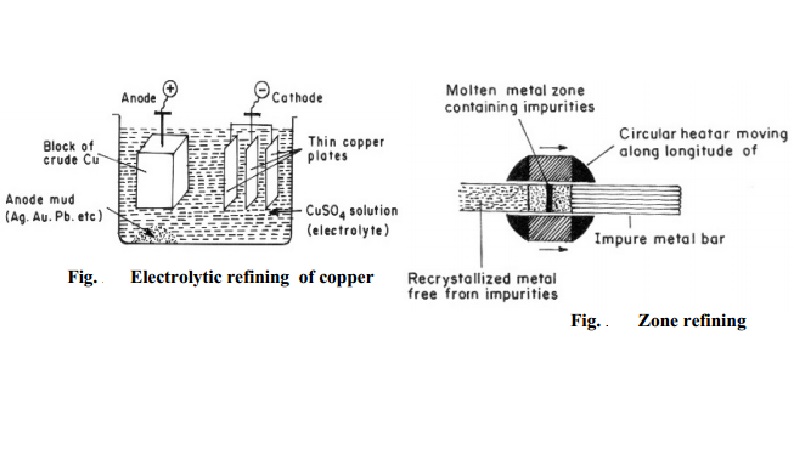

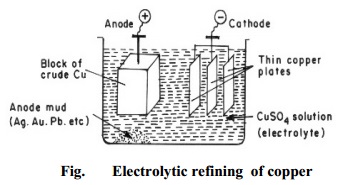

(a) Electrolytic refining

This is

one of the most convenient and important method of refining and gives a metal

of high purity. This method is applicable to many metals such as Cu, Ag, Pb, Au, Ni, Sn, Zn etc. The

blocks of impure metal form the anode and thin sheets of pure metal form the

cathode. A solution of a salt of the metal is taken as an electrolyte. On

passing an electric current through the solution pure metal dissolves from the

anode and deposits on cathode. By this process, more metal ions undergo

reduction and pure metal is deposited at the cathode. The insoluble impurities

either dissolve in the electrolyte or fall at the bottom and collect as anode mud. For example, in the refining

of copper, impurities like Fe and Zn dissolve in the electrolyte, while Au, Ag

and Pt are left behind as anode mud.

Copper: During the electrolytic refining of a copper, a thick block of impure copper is made anode, and thin plate of pure

copper is made cathode. Copper sulphate solution is used as an electrolyte. On

passing electric current, following reactions take place:

Cu2+ ions (from copper sulphate solution) go to the cathode

(negative electrode), where they are reduced to copper, which gets deposited on

the cathode.

Cu2+ + 2e-

- > Cu

Copper (of impure anode) forms copper ions, and these go into solution

of electrolyte.

Cu

- > Cu2+ + 2e-

Thus, the net result is transfer of pure copper from anode to the

cathode. Impurities like zinc, iron, etc., go into solution; while noble impurities

like silver, gold, etc., are left behind as anode mud. Copper is refined to

99.98% pure copper by electrolytic refining (Fig.).

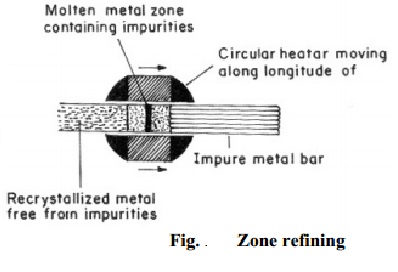

(b) Zone refining

This method is employed for preparing highly pure metal (such as

silicon, tellurium, germanium), which are used as semiconductors. It is based

on the principle that melting point of a substance is lowered by the presence

of impurities. Consequently, when an impure molten metal is cooled, crystals of

the pure metal are solidified, and the impurities remain behind the remaining

metal. (Fig.).

The

process consists in casting the impure metal in the form of a bar. A circular

heater fitted around this bar is slowly moved longitudinally from one end to

the other. At the heated zone, the bar melts, and as the heater moves on, pure

metal crystallizes, while the impurities pass into the adjacent molten part. In

this way, the impurities are swept from one end of the bar to the other. By

repeating the process, ultra pure metal can be obtained.

(c) Mond's process

Thermal methods include methods as carbonyl method, decomposition of

hydrides etc. The carbonyl method is used for the refining of metals like Ni

and Fe. For example, in case of nickel, the impure metal is heated with CO. The

nickel carbonyl thus formed is then decomposed (after distilling off the

impurities) to get pure nickel metal and CO. The process is known as Mond's process.

Ni + 4CO - > Ni(CO)4 - > Ni + 4CO

It is

based on the following facts:

1. Only nickel (and not Cu, Fe, etc.) forms a volatile carbonyl, Ni(CO)4,

when CO is passed over it at 500C.

2.

the nickel carbonyl decomposes at 1800C

to yield pure nickel.

Related Topics