Chapter: Civil : Structural dynamics of earthquake engineering

Finite element method

Finite

element method in relation to structural dynamics during earthquakes

Abstract: The basic

procedure of the finite element method, with application to simple

vibration problems, is presented in this chapter. The element stiffness, mass

(both consistent and lumped mass) and forced vibration are derived for truss

elements, shafts and beam elements. The transformation of the above matrices

with respect to the local coordinate system is now transformed to the global

system. The equations of motion of the complete system of finite element and

the incorporation of boundary conditions are discussed. Relevant computer

programs in MATHEMATICA and MATLAB are presented for truss, torsion and beam

elements. Although techniques presented are applicable to two- or-three

dimensional systems, only the one-dimensional element is treated in this

pages.

Key words: discrete element natural

frequency, modes, Rayleigh Ritz method, boundary conditions.

Introduction

The finite element method

is a powerful numerical method that is used to provide approximations to

continuous systems. The disciplines in which the finite element method can be

applied include stress analysis, heat transfer, electromagnetic analysis, fluid

flow and vibrations. Application of the finite element method to continuous

systems requires the systems to be divided into a finite number of discrete

elements. Interpolations for the dependent variables are assumed across

each element and are chosen to ensure appropriate inter-element continuity.

The interpolating functions are developed in terms of unknown values of the

dependent variables at discrete points, called nodes which are located for a

one-dimensional system at element boundaries. The defined interpolations are

used to provide approximation to the dependent variables across the system.

LagrangeŌĆÖs equations are then applied for vibration problems resulting in a set

of differential equations for the dependent variables at nodes. Total structure

is obtained as assembly of elements.

The term finite element was coined by Prof Clough. Boundary

conditions for continuous systems are classified as being of two types:

geometric boundary conditions are those which must be

satisfied according to geometric constraints. For example, u(x =

0) = 0 uŌĆ▓(x

= 0) = 0 at a fixed end of a cantilever;

ŌĆó natural

boundary conditions are those that must be satisfied as a result of free and

moment balances. For example, EI (Ōłé2u/Ōłéx2) (x = L) = 0 is a

moment boundary condition at the free end of a cantilever.

The chosen interpolating function

must satisfy geometric boundary conditions.

The type of problem that comes

from the realm of structural dynamics is restricted to the calculation of natural

frequencies and the corresponding mode shapes of free undamped vibration of

common structural components and forms. This requires the development of mass

matrix, which will represent the effect of dynamic loading (proportional to the

square of frequency) which is set up during vibration. Vibration problems are

eigenvalue problems in which eigenvalues represent the square of the natural

frequencies and eigenvectors define the shape of the structure when vibrating

at a particular frequency.

Dynamic analysis

Basically four different types of

problems can be distinguished in the field of dynamics, free vibration, steady

state vibration, transient response to known excitations and response to random

excitations.

Torsional vibration of a

shaft

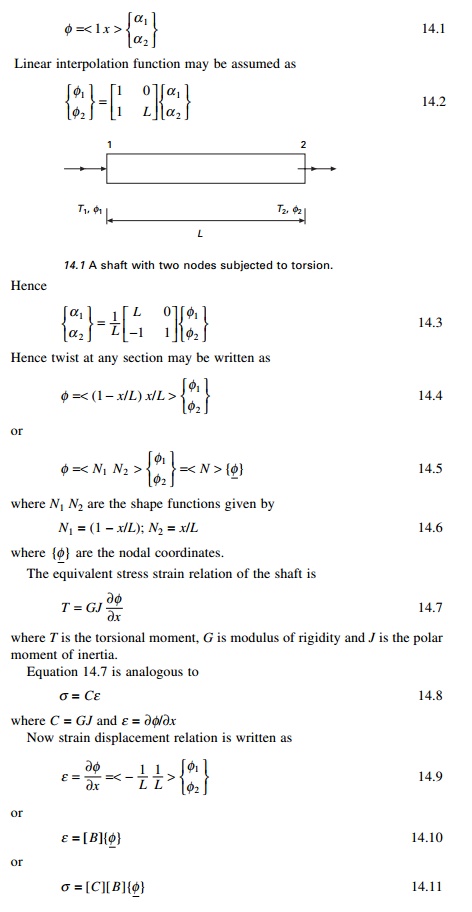

The shaft element shown in Fig. 14.1 has two nodes at its two

ends. The unknown displacements at each end are the angles of twist Žå1, Žå2. The

displacement function, which is the angle of twist, is given by

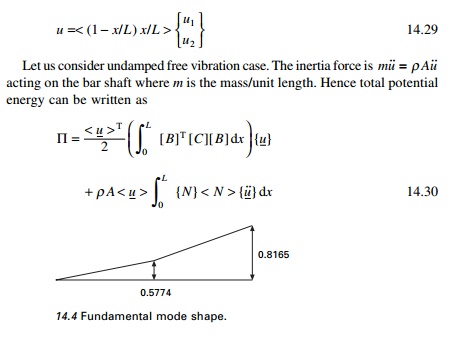

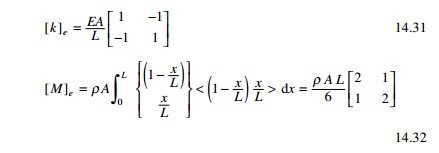

Let us consider undamped free vibration case. The inertia

force is IŽå╦Ö╦Ö acting

on the shaft where I is the mass moment of inertia/unit length. Hence total

potential energy can be written as

If [M]e is a lumped mass matrix (it

is assumed that mass is lumped at nodes)

Even though consistent mass is

more accurate, lumped mass gives better results because both stiffness and mass

are over-estimated, thus resulting in the correct answer.

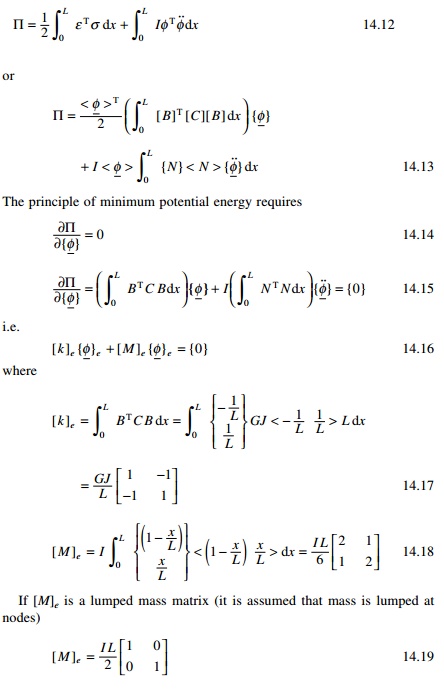

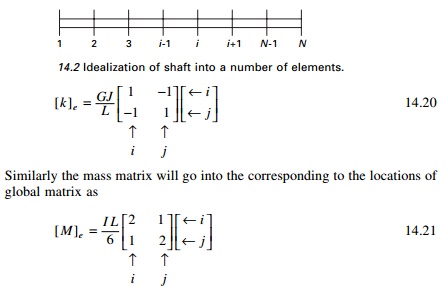

The next step is the assembly of stiffness matrix. Assume that the shaft is idealized into a number of elements as shown in Fig. 14.2 and that each element has two nodes and one degree of freedom at each node. The elements of the stiffness matrix will go into the corresponding position of global stiffness matrix as

When all elements of the element stiffness matrices and mass

matrices are assembled, and the boundary conditions incorporated, the final

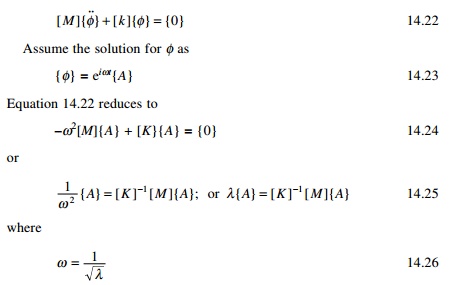

equations of free vibration is as follows

When all elements of the element stiffness matrices and mass

matrices are assembled, and the boundary conditions incorporated, the final

equations of free vibration is as follows

Equation 14.26 is a typical eigenvalue problem.

Example 14.1

A uniform shaft having one end

fixed and the other end free is divided into two equal elements as shown in

Fig. 14.3. Determine the natural frequency for torsional vibration of the

shaft.

Axial vibration of rods

The total degrees of freedom for a bar element are the axial

displacements at the ends of the element instead of the angle of twist for

torsional vibration. Let u1, u2 be the

displacements at the left end and right end of an element (see Fig. 14.1).

Axial displacement at any section is written as

Hence the stiffness matrix of an element for axial vibration

of a rod is the same as torsional vibration of the rod except that GJ is

to be replaced by EA.

Hence I in the torsional

vibration must be replaced by ŽüA for axial vibration of the rod.

Example 14.2

For the rod shown in Fig 14.3 determine the lowest frequency

for longitudinal vibration of the rod by the finite element method by

considering two elements. Solution

In the above method, admissible

functions are used as basis functions in a RayleighŌĆ'Ritz approximation to

solution of an eigenvalue problem. Sometimes the RayleighŌĆ'Ritz method is

difficult to apply to vibration problems. The assumed modes method, introduced

in the next section, is based on application of LagrangeŌĆÖs equations and leads

to the same approximation as that for the same set of interpolating functions

as the RayleighŌĆ'Ritz method. In the next section we will use the finite element

method for the longitudinal vibration by the assumed modes method.

14.5 Assumed

modes method

Example 14.3

Consider a forced vibration of a

longitudinal bar as shown in Fig. 14.5. The displacement u is a function

of spatial coordinate x and time t, i.e. u(x, t).

Program

14.1: MATLAB program for the assumed modes method

%example 14.3

% assumed modes method to

determine natural frequencies m mode %shapes, and forced response of tapered

bar with attached mass and spring clc;

close all; digits(5); x=sym(ŌĆśxŌĆÖ);

%parameters

e=200*10^9; % youngs modulus in

N/sq.m rho=7800; % mass density in kgm/cu.m l=4.0; % span of the beam in m

m=10; % concentrated mass in kgm

k=3*10^7; % spring constant %functions

a=0.001*(1-.005*x);% area in sq.m

u(1)=sin(pi*x/(2*l)); % assumed modes u(2)=sin(3*pi*x/(2*l)); u(3)=sin(5*pi*x/(2*l));

%mass and stiffness matrices for

i=1:3

for j=1:i c1=subs(u(i),x,l)*subs(u(j),x,l);

Mint=rho*a*u(i)*u(j);

Kint=e*a*diff(u(i),x)*diff(u(j),x);

M(i,j)=int(Mint,x,0,l)+m*c1;

K(i,j)=int(Kint,x,0,l)+k*c1;

M(j,i)=M(i,j);

K(j,i)=K(i,j); end

end

disp(ŌĆś stiffness matrixŌĆÖ)

K=vpa(K)

disp(ŌĆś mass matrixŌĆÖ) M=vpa(M)

K1=double(K); M1=double(M); C=inv(K1)*M1; [V,D]=eig(C);

for i=1:3 w(i)=1/sqrt(D(i,i));

end

disp(ŌĆś natural frequencies in

rad/secŌĆÖ) w=vpa(w);disp(wŌĆÖ)

%Normalize mode shape vectors

E=VŌĆÖ*M*V;

for j=1:3 for i=1:3

P(i,j)=V(i,j)/sqrt(E(j,j)); end

end

disp(ŌĆś modal matrixŌĆÖ)

P=vpa(P);disp(P) %mode shapes xx=linspace(0,l,37); P1=single(P);

for k=1:37 for i=1:3

v(i,k)=0; for j=1:3

v(i,k)=v(i,k)+P1(j,i)*subs(u(j),x,xx(k)); end

end end

plot(xx,v(1,:),ŌĆÖkŌĆÖ,xx,v(2,:),ŌĆÖ*kŌĆÖ,xx,v(3,:),ŌĆÖŌĆ'kŌĆÖ);

xlabel(ŌĆś x (m)ŌĆÖ)

ylabel(ŌĆś w(x) mŌĆÖ)

legend(ŌĆś 1st modeŌĆÖ, ŌĆś2nd modeŌĆÖ, ŌĆś3rd modeŌĆÖ)

Output for example 14.3 stiffness

matrix

K =

[ .91319e8, -.29250e8, .30139e8]

[ -.29250e8, .57987e9, -.26250e8] [ .30139e8, -.26250e8, .15570e10]

mass matrix M =

[ 25.381, -9.9368, 9.9930] [

-9.9368, 25.437, -9.9368] [ 9.9930, -9.9368, 25.442]

natural frequencies in rad/sec

1895.7 5062.1 8984.0

modal matrix

[ .19713, -.94408e-1, -.53048e-1]

[ -.26221e-2, -.20576, .89500e-1] [ .79332e-3, .28353e-1, .22280]

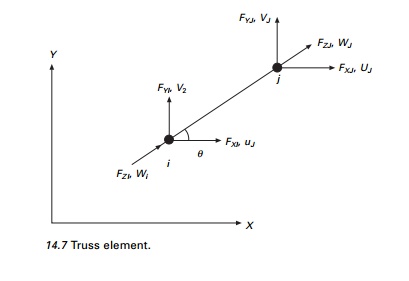

Truss element

Consider a truss element oriented as shown in Fig. 14.7 in the

global coordinate system.

14.7.1 Element

stiffness and mass matrices

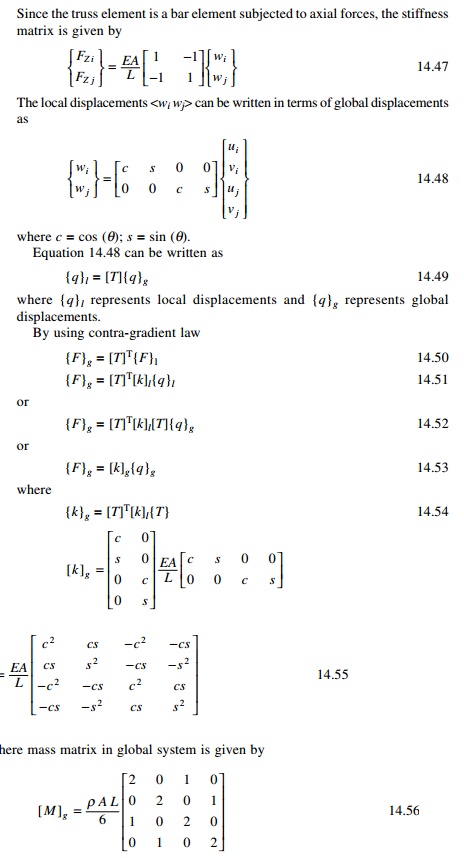

Since the truss element is a bar element subjected to axial

forces, the stiffness matrix is given by

The local displacements <wi wj>

can be written in terms of global displacements as

where {q}l represents local

displacements and {q}g represents global

displacements.

By using contra-gradient law

{F}g = [T]T{F}l --- -- 14.50

{F}g = [T]T[k]l{q}l

--- -- 14.51

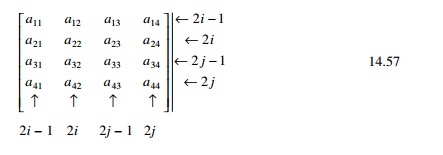

14.7.2 Assembly

The elements of the stiffness matrix and mass matrix will

assemble in the proper location of structural stiffness matrix as

3 Application of

boundary conditions

ŌĆó If any of

the degrees of freedom is constrained, the row and column corresponding to that

degree of freedom are deleted from the assembled stiffness or mass matrix.

ŌĆó Add

springs of very high stiffness at the constrained degree of freedom.

ŌĆó Use

Lagrangian multiplier method to incorporate the constraints.

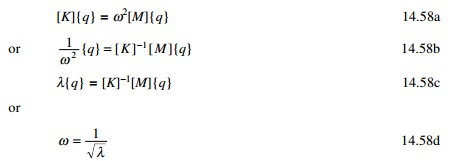

4 Solve as an

eigenvalue problem

and the corresponding mode shape is also obtained.

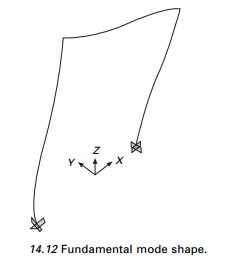

Example 14.4

Use the finite element method to obtain the lowest natural

frequency for the

truss shown in Fig. 14.8. The data are: L1 =

1.2 m; L2 = 2.68 m; L3 = 2.4 m; L4

= 1.2 m; ╬Ė = 63.43┬ o ; sin ╬Ė = 0.894; cos ╬Ė = 0.447

E = 2 ├- 1011

N/m2; A = 0.04 m2; Žü = 7600 kg/m3.

Assembling all the elements and eliminating the 1st, 2nd, 7th

and 8th (boundary conditions) we get resulting stiffness and mass matrices as

Program

14.2: MATLAB program for free vibration of trusses

Trussdyn

% solution of plane

truss free vibration by finite element method

clc;

K=zeros(12,12);

M=zeros(10,10);

e=200e9;

a=0.04;

l1=1.2;

rho=7600;

l2=2.683;

l3=2.4;

l4=1.2;

l5=2.4;

% calculate element

lengths

% calculate element

stiffness

k1=PlaneTrussElementStiffness(e,a,l1,0);

m1=PlaneTrussElementMass(rho,a,l1,0);

k2=PlaneTrussElementStiffness(e,a,l2,63.43);

m2=PlaneTrussElementMass(rho,a,l2,63.43);

k3=PlaneTrussElementStiffness(e,a,l3,90);

m3=PlaneTrussElementMass(rho,a,l3,90);

k4=PlaneTrussElementStiffness(e,a,l4,0);

m4=PlaneTrussElementMass(rho,a,l4,0);

% assemble element

stiffness to global stiffness

K=PlaneTrussAssemble(K,k1,4,3);

K=PlaneTrussAssemble(K,k2,1,3);

K=PlaneTrussAssemble(K,k3,2,3);

K=PlaneTrussAssemble(K,k4,1,2);

M=PlaneTrussAssemble(M,m1,4,3);

M=PlaneTrussAssemble(M,m2,1,3);

M=PlaneTrussAssemble(M,m3,2,3);

M=PlaneTrussAssemble(M,m4,1,2);

format long;

ks=1;

% apply boundary conditions for

stiffness matrix and mass K(9,1)=ks;

K(10,2)=ks;

K(11,7)=ks;

K(12,8)=ks;

M(9,1)=ks;

M(10,2)=ks;

M(11,7)=ks;

M(12,8)=ks;

K(1,9)=ks;

K(2,10)=ks;

K(7,11)=ks;

K(8,12)=ks;

M(1,9)=ks;

M(2,10)=ks;

M(7,11)=ks;

M(8,12)=ks;

invk=inv(K);

km=invk*M;

[ms,ns]=size(M);

% eigen values and eigen vectors

[evec,ev]=eig(km);

for i=1:ms ee(i)=1/ev(i,i);

end Qh=max(ee)+0.001; Ql=0;

for i=1:ms for j=1:ms

if ee(j) > Ql & ee(j) < Qh k=j;

Qh=ee(j); else

end end Ql=Qh;

Qh=max(ee)+0.001;

om1(i)=ee(k);

omega(i)=sqrt(ee(k)); for m=1:ms

p1(m,i)=evec(m,k); end

end

%Normalizing the mode shape

L=p1'*m*p1;

%develop modal matrix for i=1:ms

for j=1:ms p(i,j)=p1(i,j)/L(j,j);

end end

disp(ŌĆś Natural frequencies in

rad/secŌĆÖ) disp(omegaŌĆÖ)

disp(ŌĆś normalized modal vector ŌĆś)

disp(p)

function y =

PlaneTrussElementStiffness(E,A,L, theta) %PlaneTrussElementStiffness This

function returns the element

%stiffness

matrix for a plane truss

%element

with modulus of elasticity E,

%cross-sectional

area A, length L, and

%angle

theta (in degrees).

%The size

of the element stiffness

%matrix is

4 x 4.

x = theta*pi/180; C = cos(x);

S = sin(x);

y =

E*A/L*[C*C C*S -C*C -C*S ; C*S S*S -C*S -S*S ; -C*C -C*S C*C C*S ; -C*S -S*S

C*S S*S];

function y =

PlaneTrussElementMass(rho,A,L, theta) %PlaneTrussElementStiffness This function

returns the mass

%matrix

for a plane truss

%element

with mass density rho,

%cross-sectional

area A, length L, and

%angle

theta (in degrees).

%The size

of the element stiffness

%matrix is

4 x 4.

x = theta*pi/180; C = cos(x);

S = sin(x);

% for consistent mass use the following

y = (rho*A*L/6)*[2 0 1 0 ; 0 2 0

1 ;1 0 2 0 ; 0 1 0 2]; %for lumped mass use the following %y=(rho*A*L/2)*[1 0 0

0;0 1 0 0;0 0 1 0;0 0 0 1];

function y = PlaneTrussAssemble(K,k,i,j)

%PlaneTrussAssemble This function assembles the element

stiffness

%matrix k

of the plane truss element with nodes

%i and j

into the global stiffness matrix K.

%This

function returns the global stiffness

matrix K after the element stiffness matrix

% k is assembled. lm(1)=2*i-1;

lm(2)=2*i; lm(3)=2*j-1; lm(4)=2*j;

for m=1:4 ii=lm(m); for n=1:4

jj=lm(n);

K(ii,jj)=K(ii,jj)+k(m,n); end

end

y = K;

OUTPUT

Natural frequencies in rad/sec 1.0e+003 *

0.00100000000000

0.00100000000000

1.25105969735243

3.23474518944287

4.53189428385080

Beam element

Consider a uniform beam element of length L and

cross-sectional area A and mass density Žü as shown in Fig. 14.9. The

modulus of elasticity of the material is E and I is the second

moment of area. The unknown displacement of the element are deflections and

rotations at the two ends, in total four degrees of freedom for each element or

two degrees of freedom/node. The displacement function is represented by the

equation given by

Program 14.3: MATHEMATICA program for

evaluation of stiffness matrix, and mass matrix of a beam element

Example 14.5

Find the fundamental frequency of

a simply supported uniform beam shown in Fig. 14.10.

Example 14.6

Set up the system of equation

governing free vibration in its own plane of the portal frame shown in Fig.

14.11.

A = 1.851

87 ├- 10ŌĆ'5;

I = 2.857 85 ├- 10ŌĆ'11;

E = 210 GPa;

Žü = 25 613.5 kg/m3; L

= 0.2413 m.

Program 14.4: MATLAB program

to find the natural frequency of beams or rigid frames

FRAMEDYN

% dynamics of plane frame by

finite element method clc;

nj=7;

ne=6;

neq=3*nj;

K=zeros(neq,neq);

M=zeros(neq,neq);

%give nodi and nodj of each member

nodi=[1 2 3 4 5 6];

nodj=[2 3 4 5 6 7];

%give the values of e,a,i angle

and lengths of members e=210e9;

a=[1.85187e-5 1.85187e-5

1.85187e-5 1.85187e-5 1.85187e-5 1.85187e-5] ; mi=[2.85785e-11 2.85785e-11

2.85785e-11 2.85785e-11 2.85785e-11...

2.85785e-11]; angle=[90 90 0 0

-90 -90];

l=[.12065 .12065 .12065 .12065

.12065 .12065];

%give

density of the material

rho=25613.5;

%number of constraint degrees of

freedom nbou=6;

%the numbers of constrained

degrees of freedom nb=[1 2 3 19 20 21];

%

form 6 x 6 element stiffness and mass matrix and

assemble wilson method for n=1:ne

i=nodi(n);

j=nodj(n);

k=PlaneFrameElementStiffness(e,a(n),mi(n),l(n),angle(n));

m=PlaneFrameElementMass(rho,a(n),l(n),angle(n));

K=PlaneFrameAssemble(K,k,i,j);

M=PlaneFrameAssemble(M,m,i,j);

end

%apply

boundary conditions using wilson method

for i=1:nbou ii=nb(i); for j=1:neq

K(ii,j)=0.0;

K(j,ii)=0.0;

M(ii,j)=0.0;

M(j,ii)=0.0; end K(ii,ii)=1; M(ii,ii)=1;

end

% find inv(K)*M invk=inv(K); km=invk*M;

format long;

%find the eigen values and mode

shapes of inv(K)*M [ms,ns]=size(M);

%%eigen values and eigen vectors

[evec,ev]=eig(km);

for i=1:ms ee(i)=1/ev(i,i);

end Qh=max(ee)+0.001; Ql=0;

for i=1:ms for j=1:ms

if ee(j) > Ql & ee(j) < Qh k=j;

Qh=ee(j); else

end end Ql=Qh;

Qh=max(ee)+0.001;

om1(i)=ee(k);

omega(i)=sqrt(ee(k)); for m=1:ms

p1(m,i)=evec(m,k); end

end

%Normalizing the mode shape

L=p1'*m*p1;

%develop modal matrix for i=1:ms

for j=1:ms p(i,j)=p1(i,j)/L(j,j); end

end

disp(ŌĆś Natural frequencies in

rad/secŌĆÖ) disp(omegaŌĆÖ)

disp(ŌĆś normalized modal vector ŌĆÖ)

disp(p)

function y =

PlaneFrameElementStiffness(E,A,I,L,theta) %PlaneFrameElementStiffness This

function returns the element

%stiffness

matrix for a plane frame

element with modulus of elasticity E,

%cross-sectional

area A, moment of

%inertia

I, length L, and angle

%theta (in

degrees).

%The size

of the element stiffness

%matrix is

6 x 6.

x = theta*pi/180; C = cos(x);

S = sin(x);

w1 = A*C*C + 12*I*S*S/(L*L);

w2 = A*S*S + 12*I*C*C/(L*L);

w3 = (A-12*I/(L*L))*C*S;

w4 = 6*I*S/L;

w5 = 6*I*C/L;

y = E/L*[w1

w3 -w4 -w1 -w3 -w4 ; w3 w2 w5 -w3 -w2 w5 ; -w4 w5 4*I w4 -w5 2*I ; -w1 -w3 w4

w1 w3 w4 ;

-w3 -w2 -w5 w3 w2 -w5 ; -w4 w5 2*I w4 -w5 4*I];

function y =

PlaneFrameElementMass(rho,A,l, theta) %PlaneFrameElementMass This function

returns the mass

%matrix

for a plane frame

%element

with mass density rho,

%cross-sectional

area A, length L, and

%angle

theta (in degrees).

%The size

of the element stiffness

%matrix is

6 x 6.

x = theta*pi/180; C = cos(x);

S = sin(x);

% for consistent mass use the following

%mass matrix of frame element consistent matrix

f33 _ 00=[0 . 333,0,0,0 .

167,0,0;0,0 . 37143,0 . 05238*l,0,0 . 12857, -

0.03095*l;0,.05238*l,.00952*l*l,0,0.03095*l,-.00714*l*l;

0.167,0,0,0.333,0,0;0,0.12857,0.03095*l,0,0.37143,-0.05238*l;0,-0.03095*l,-0.00714*l*l,0,-0.05238*l,0.00952*l*l];

t=[C,S,0,0,0,0;-S,C,0,0,0,0;0,0,1,0,0,0;0,0,0,C,S,0;0,0,0,-S,C,0;0,0,0,0,0,1];

n=tŌĆÖ*f33_00*t;

%lumped mass

%n=[0.5,0,0,0,0,0;0,.5,0,0,0,0;0,0,0,0,0,0;0,0,0,.5,0,0;0,0,0,0,.5,0;0,0,0,0,0,0];

y=rho*A*l*n;

function y =

PlaneFrameAssemble(K,k,i,j)

%PlaneFrameAssemble This function

assembles the element stiffness

%matrix k

of the plane frame element with nodes

i and j into the global stiffness matrix K.

%This

function returns the global stiffness

%matrix K

after the element stiffness matrix

%k is

assembled.

lm(1)=3*i-2; lm(2)=3*i-1;

lm(3)=3*i; lm(4)=3*j-2; lm(5)=3*j-1; lm(6)=3*j; for l=1:6

ii=lm(l); for n=1:6

jj=lm(n);

K(ii,jj)=K(ii,jj)+k(l,n); end

end

y = K;

OUTPUT

Natual frequencies in rad/sec 1.0e+004 *

0.00010000000000

0.01957884271941

0.07771746384284

0.12745125003361

0.13873461021422

0.31352858884033

Forced vibration of a beam

Example 14.7

Use a two element model for the

beam to determine the steady state response of the system shown in Fig. 14.13.

clc;

digits(5);

L=8; % length in m

rho=7600; %mass density in

kg/cu.m e=2e11; %youngs modulus of the material i=1.6*10^-6; % moment of

inertia in m^4 a=3.6*10^-3 % area in m^2

m=20; % mass of hanging block in

kg k=3*10^4; % stiffness of discrete spring in N/m s=L/2; %element length

f0=2500; % excitation amplitude

in N om=80; %excitation frequency in rad/s disp(ŌĆśglobal mass matrixŌĆÖ)

M=rho*a*s/420*[4*s^2,13*s,-3*s^2,0,0;13*s,312,0,-13*s,0;...

-3*s^2,0,8*s^2,-3*s^2,0;0,-13*s,-3*s^2,4*s^2,0;...

0,0,0,0,420*m/(rho*a*s)]; K=e*i/s^3*[4*s^2,-6*s,2*s^2,0,0;-6*s,24+k*s^3/(e*i),0,6*s,-k*s^3/(e*i);...

2*s^2,0,8*s^2,2*s^2,0;0,6*s,2*s^2,4*s^2,0;...

0,-k*s^3/(e*i),0,0,k*s^3/(e*i)];

M1=vpa(M);disp(M1) K1=vpa(K);disp(K1)

%natural frequencies

W2=eig(inv(K)*M); for i=1:5

w(i)=1/sqrt(W2(i)); end

disp(ŌĆś natural frequenciesŌĆÖ)

w=vpa(wŌĆÖ)

%force vector disp(ŌĆś force

vectorŌĆÖ)

f=f0*s*[-s/48;13/16;-s/8;-5*s/192;0]

%use of undetermined coefficients z=-om^2*M+K;

W=inv(z)*f;

x=linspace(0,L,21); for k=1:21

if x(k) <s xi=x(k)/s;

y(k)=(xi-2*xi^2+xi^3)*W(1)+(3*xi^2-2*xi^3)*W(2);

y(k)=y(k)+(-xi^2+xi^3)*W(4);

else xi=(x(k)-s)/s;

y(k)=(1-3*xi^2+2*xi^3)*W(2)+(xi^2-2*xi^2+xi^3)*W(3);

y(k)=y(k)+(-xi^2+xi^3)*W(4); end

end plot(x,y,ŌĆś-kŌĆÖ); xlabel(ŌĆś

x(m)ŌĆÖ);

ylabel(ŌĆśw(x) (m)ŌĆÖ);

W=vpa(W);

disp(ŌĆś steady state amplitude in mŌĆÖ);disp(W)

OUTPUT

global mass matrix

[ 16.677, 13.550, -12.507, 0.,

0.] [ 13.550, 81.298, 0., -13.550, 0.] [ -12.507, 0., 33.353, -12.507, 0.] [

0., -13.550, -12.507, 16.677, 0.] [ 0., 0., 0., 0., 20.]

[ .32000e6, -.12000e6, .16000e6, 0., 0.]

[ -.12000e6, .15000e6, 0.,

.12000e6, -30000.] [ .16000e6, 0., .64000e6, .16000e6, 0.]

[ 0., .12000e6, .16000e6,

.32000e6, 0.] [ 0., -30000., 0., 0., 30000.]

natural frequencies w =

15.162

42.623

74.044

186.76

339.31

force vector f =

1.0e+003

*

-0.8333 8.1250 -5.0000 -1.0417 0

steady state amplitude in m -.43073e-1

-.10930e-1

.25384e-1 -.22861e-1

.33458e-2

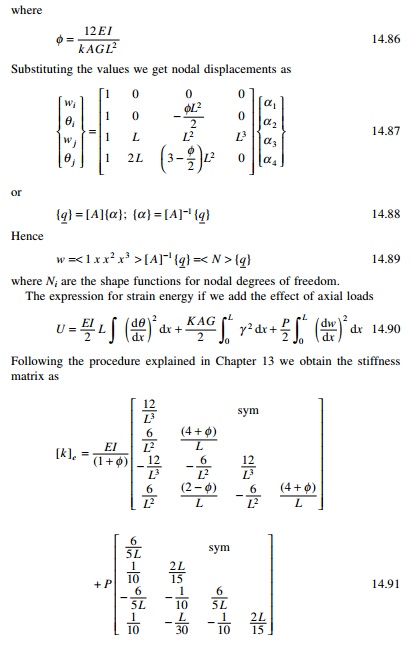

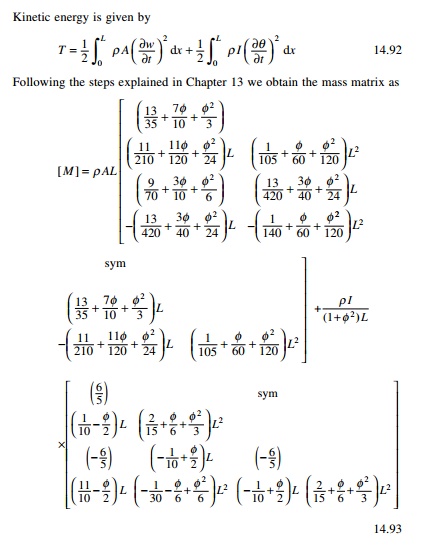

Vibration of a Timoshenko beam

We have already seen that

EulerŌĆ'BernoulliŌĆÖs theory predicts the frequencies for a shallow beam with

adequate precision. But with the increasing depth of the beam, the effect of

transverse shear deformation and rotary inertia become more important. Many

varieties of Timoshenko beam elements have been proposed. It has been observed

that the element described below is adequate for practical use.

The deflection function is given by

where k is TimoshenkoŌĆÖs

shear constant = 5/6 for rectangular section and 9/10 for circular sections.

Example 14.8

Find the fundamental frequency of

a Timoshenko beam by using the program ŌĆśTimoshenkovibŌĆÖ given that

E = 210

GPa; G = 70 GPa; Žü = 7800 kg/m3, A =

1.85187eŌĆ'5;

I =

2.85785eŌĆ'11; P = 200 N; k = 5/6.

The lowest frequency obtained from the program is 11.7 rad/s.

Program 14.6: MATLAB program

to find the frequency of a Timoshenko beam

TIMOSHENKOVIB

% dynamics of Timoshenko beam by

finite element method clc;

ne=5;

nj=ne+1;

neq=2*nj;

K=zeros(neq,neq);

M=zeros(neq,neq);

%give nodi and nodj of each member

for i=1:nj

nodi(i)=i;

nodj(i)=i+1; end

%give the values of e,g,a,i and

lengths of beam e=210e9;

g=70e9;

a=[1.85187e-5 1.85187e-5

1.85187e-5 1.85187e-5 1.85187e-5 1.85187e-5] ; mi=[2.85785e-11 2.85785e-11

2.85785e-11 2.85785e-11 2.85785e-11...

2.85785e-11]; angle=0;

L=10;

for i=1:ne l(i)=L/ne; end

%give

density of the material

rho=7800.0;

%give axial load of the member

P=200;

%give timoshenko shear constant

ko=5/6 for rect ko=9/10 for circular ko=5/6;

%number of constraint degrees of

freedom nbou=2;

%the numbers of constrained

degrees of freedom nb=[1 2*nj-1];

%

form 6 x 6 element stiffness and mass matrix and

assemble wilson method for n=1:ne

i=nodi(n);

j=nodj(n);

phi(n)=12.0*e*mi(n)/(ko*a(n)*g*l(n)^2);

k=TimoshenkoElementStiffness(e,a(n),mi(n),l(n),P,phi(n));

m=TimoshenkoElementMass(rho,a(n),mi(n),l(n),phi(n));

K=TimoshenkoAssemble(K,k,i,j);

M=TimoshenkoAssemble(M,m,i,j);

end

%apply boundary conditions using

wilson method for i=1:nbou

ii=nb(i); for j=1:neq

K(ii,j)=0.0;

K(j,ii)=0.0;

M(ii,j)=0.0;

M(j,ii)=0.0; end K(ii,ii)=1; M(ii,ii)=1;

end

%find

inv(K)*M

invk=inv(K);

km=invk*M; format long;

%find the eigen values and mode

shapes of inv(K)*M [ms,ns]=size(M);

%%eigen values and eigen vectors

[evec,ev]=eig(km);

for i=1:ms ee(i)=1/ev(i,i);

end Qh=max(ee)+0.001; Ql=0;

for i=1:ms for j=1:ms

if ee(j) > Ql & ee(j) < Qh kl=j;

Qh=ee(j); else

end end Ql=Qh;

Qh=max(ee)+0.001;

om1(i)=ee(kl);

omega(i)=sqrt(ee(kl)); for

lm=1:ms

p1(lm,i)=evec(lm,kl);

end

end

%Normalizing the mode shape

LL=p1'*M*p1;

%develop modal matrix

for i=1:ms

for

j=1:ms

p(i,j)=p1(i,j)/LL(j,j);

end

end

disp(ŌĆś Natural frequencies in rad/secŌĆÖ)

disp(omegaŌĆÖ)

disp(ŌĆś normalized modal vector ŌĆś)

disp(p)

function y = TimoshenkoElementStiffness(E,A,I,L,P,phi)

%TimoshenkoElementStiffness This function returns the element

% stiffness matrix for a Timoshenko beam element

% element with modulus of elasticity E,

% cross-sectional area A, moment of

% inertia I, length L, and angle

% theta (in degrees).

% The size of the element stiffness

% matrix is 6 x 6.

con=E*I/(1+phi);

w1 = 12*con/L^3+1.2*P/L;

w2 = 6*con/L^2+P/10;

w3 = con*(4+phi)/L+2*P*L/15;

w4 = con*(2-phi)/L-P*L/30;

y = [w1,w2,-w1,w2;w2,w3,-w2,w4;-w1,-w2,w1,-w2;w2,w4,-w2,w3];

function y =

TimoshenkoElementMass(rho,A,I,l,phi) %TimoshenkoElement Mass matrix This

function returns the mass

%matrix

for a Timoshenko beam

%element

with mass density rho,

%cross-sectional

area A, length L, and

%angle

theta (in degrees).

%The size

of the element stiffness

matrix is 4 x 4. a(1,1)=13/35+7*phi/10+phi^2/3;

a(1,2)=(11/210+11*phi/120+phi^2/24)*l; a(1,3)=9/70+3*phi/10+phi^2/6;

a(1,4)=-(13/420+3*phi/40+phi^2/24)*l;

a(2,2)=(1/105+phi/60+phi^2/120)*l^2;

a(2,3)=(13/420+3*phi/40+phi^2/24)*l;

a(2,4)=-(1/140+phi/60+phi^2/120)*l^2; a(3,3)=(13/35+7*phi/10+phi^2/3);

a(3,4)=-(11/210+11*phi/120+phi^2/24); a(4,4)=(1/105+phi/60+phi^2/120)*l^2;

b(1,1)=1.2;

b(1,2)=(0.1-0.5*phi)*l;

b(1,3)=-1.2; b(1,4)=(0.1-0.5*phi)*l; b(2,2)=(2/15+phi/6+phi^2/3)*l^2;

b(2,3)=(-1/10+phi/2)*l; b(2,4)=(-1/30-phi/6+phi^2/6)*l^2; b(3,3)=1.2;

b(3,4)=(-0.1+0.5*phi)*l; b(4,4)=(2/15+phi/6+phi^2/3)*l^2; for i=2:4

for j=1:(i-1) a(i,j)=a(j,i); b(i,j)=b(j,i);

end end

y=(rho*A*l)*a+(rho*I/((1+phi^2)*l))*b;

function y = TimoshenkoAssemble(K,k,i,j)

%Timoshenko beam This function assembles the element stiffness

%matrix k

of the Timoshenko beam with nodes

%i and j

into the global stiffness matrix K.

%This

function returns the global stiffness

%matrix K

after the element stiffness matrix

%k is

assembled.

lm(1)=2*i-1; lm(2)=2*i;

lm(3)=2*j-1; lm(4)=2*j; for l=1:4

ii=lm(l); for n=1:4

jj=lm(n);

K(ii,jj)=K(ii,jj)+k(l,n); end

end

y = K;

end

y = K;

OUTPUT

Natual frequencies in rad/sec 1.0e+002 *

0.01000000000000 0.11701648818926 0.23474939088448 0.35376511095837

0.47263579452189 0.61764685636320 0.77724091967848 0.93007476129177

1.12011725011258 1.36597976298605 1.66895296196556 1.66895296196556

Summary

In this chapter, free and forced vibrations of beams, trusses

and frames are discussed. In the next chapter, we will apply other numerical

methods such as differential quadrature and transformation methods to find the

natural frequencies of structures.

Related Topics