Chapter: Modern Analytical Chemistry: Gravimetric Methods of Analysis

Theory and Practice of Precipitation Gravimetry: Occlusions

Occlusions

Which are a second

type of coprecipitated impurity, occur when physically adsorbed interfering ions

become trapped within

the growing precipitate.

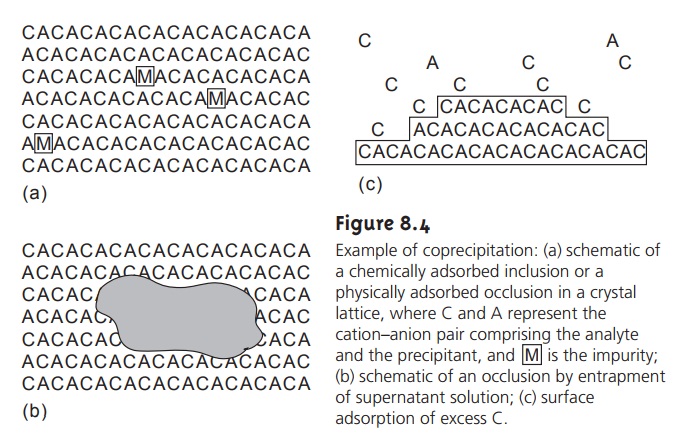

Occlusions form in two ways.

The most common

mechanism occurs when physically

adsorbed ions are

surrounded by additional precipitate before they

can be desorbed or displaced (see Figure

8.4a). In this

case the precipitate’s mass is always

greater than expected. Occlusions also form when rapid precipitation traps a pocket of solution within the growing precipitate (Figure 8.4b). Since

the trapped solution

contains dis- solved solids,

the precipitate’s mass normally increases. The mass of the precipitate may be less than expected, however,

if the occluded material consists

primarily of the analyte in a lower-molecular-weight form

from that of the precipitate.

Occlusions are minimized by maintaining the precipitate in

equilibrium with its supernatant solution

for an extended time. This process is called digestion and may be carried out

at room temperature or at an elevated temperature. During di-

gestion, the dynamic nature of the solubility–precipitation equilibrium, in which

the precipitate dissolves and re-forms, ensures

that occluded material

is eventually exposed to the supernatant solution. Since the rate of dissolution and reprecipita-

tion are slow, the chance

of forming new occlusions is minimal.

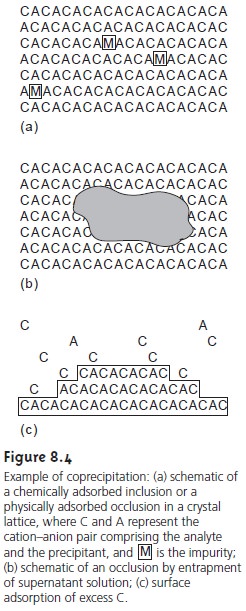

After precipitation is complete the surface continues to attract ions from solu- tion (Figure 8.4c). These surface adsorbates,

which may be chemically or physically

adsorbed, constitute a third type of coprecipitated impurity. Surface adsorption is minimized by decreasing the precipitate’s available

surface area. One benefit of di-

gestion is that it also increases the average size of precipitate particles. This is not

surprising since the

probability that a particle will

dissolve is inversely proportional to its size. During digestion

larger particles of precipitate increase

in size at the ex- pense

of smaller particles. One consequence of forming fewer

particles of larger

size is an overall

decrease in the precipitate’s surface

area. Surface adsorbates also may be removed

by washing the precipitate. Potential

solubility losses, however,

cannot be ignored.

Inclusions, occlusions, and surface adsorbates are called

coprecipitates because they represent soluble

species that are brought into solid form along with the de- sired precipitate. Another source

of impurities occurs

when other species

in solu- tion precipitate under the conditions of the analysis. Solution conditions necessary to minimize the solubility of a desired

precipitate may lead

to the formation of an additional precipitate that interferes in the analysis. For example, the precipitation

of nickel dimethylgloxime requires a pH that

is slightly basic.

Under these condi- tions, however, any Fe3+ that might

be present precipitates as Fe(OH)3. Finally, since most precipitants are not selective

toward a single analyte, there is always a

risk that the precipitant will react, sequentially, with more than one species.

The

formation of these

additional precipitates can usually be minimized by carefully controlling solution conditions. Interferents forming precipitates that are less soluble

than the analyte

may be precipitated and removed

by filtration, leaving the analyte behind in solution. Alternatively, either the analyte

or the interferent can be masked using

a suitable complexing agent, preventing its precipitation.

Both of the above-mentioned approaches are illustrated in Fresenius’s analyti- cal method for determining Ni and Co in ores

containing Pb2+, Cu2+,

and Fe3+ as potential interfering ions. The

ore is dissolved in a so- lution containing H2SO4, selectively precipitating Pb2+ as PbSO4. After filtering, the supernatant solution is treated with H2S. Because

the solution is strongly acidic,

however, only CuS precipitates. After

removing the CuS by filtration, the solution is made

basic with ammonia

until Fe(OH)3 precipitates. Cobalt and nickel,

which form soluble amine

complexes, remain in solution.

In some situations the rate at which a precipitate forms

can be used to separate an analyte from a potential interferent. For example, due to similarities in their chemistry, a gravimetric analysis for Ca2+ may be adversely affected by the presence of Mg2+. Precipitates of Ca(OH)2, however, form more rapidly

than precipitates of Mg(OH)2. If Ca(OH)2

is filtered before Mg(OH)2 begins to precipitate, then a

quantitative analysis for Ca2+ is

feasible.

Finally, in some cases it is easier

to isolate and weigh both the analyte

and the interferent. After recording its weight, the mixed precipitate is treated to convert at least

one of the two precipitates to a new chemical form. This new mixed precipitate is also isolated and weighed. For example, a mixture containing Ca2+ and Mg2+ can be analyzed for both cations by first isolating a mixed precipitate of CaCO3 and MgCO3. After

weighing, the mixed

precipitate is heated,

converting it to a mixture of CaO and MgO. Thus

Grams of mixed precipitate 1 = grams CaCO3 + grams

MgCO3

Grams of mixed precipitate 2 = grams CaO + grams MgO

Although these equations contain four unknowns (grams CaCO3,

grams MgCO3, grams CaO, and grams MgO), the stoichiometric relationships between CaCO3 and CaO

Moles CaCO3 = moles CaO

and between MgCO3 and MgO

Moles MgCO3 = moles MgO

provide enough additional information to determine the amounts of both Ca2+ and

Mg2+ in

the sample.*

Related Topics