Chapter: Modern Analytical Chemistry: Gravimetric Methods of Analysis

Theory and Practice of Precipitation Gravimetry: Controlling Particle Size

Controlling Particle Size

Following precipitation and digestion, the precipitate

must be separated from the supernatant solution

and freed of any remaining impu- rities, including residual solvent. These tasks

are accomplished by filtering, rinsing, and drying the precipitate. The size of the precipitate’s particles determines the

ease and success of filtration. Smaller,

colloidal particles are difficult to filter because they may readily pass through the pores of the filtering device. Large, crystalline particles, however,

are easily filtered.

By

carefully controlling the precipitation reaction

we can significantly increase

a precipitate’s average

particle size. Precipitation consists of two

distinct events: nu- cleation, or the initial

formation of smaller

stable particles of precipitate, and the

subsequent growth of these particles. Larger particles form when the rate of particle

growth exceeds the rate of nucleation.

where Q is the

solute’s actual concentration, S is the solute’s expected concentra-

tion at equilibrium, and Q –

S

is a measure

of the solute’s supersaturation when

precipitation begins.

A large, positive

value of RSS indicates that a solution

is highly supersaturated. Such solutions are unstable and show high rates of nucle- ation, producing a precipitate consisting of numerous small particles. When RSS is small, precipitation is more likely to occur by particle growth than by nucleation.

Examining equation 8.12 shows that we can minimize RSS by

either decreasing the solute’s

concentration or increasing the precipitate’s solubility. A precipitate’s

solubility usually increases

at higher temperatures, and adjusting pH may affect a

precipitate’s solubility if it contains

an acidic or basic anion.

Temperature and pH, therefore, are useful ways to increase

the value of S. Conducting the precipitation in a dilute solution

of analyte, or adding the precipitant slowly

and with vigorous

stir- ring are ways

to decrease the

value of Q.

There are, however, practical limitations to minimizing RSS. Precipitates that are extremely insoluble, such as Fe(OH)3 and PbS, have such small

solubilities that a large

RSS cannot be avoided.

Such solutes inevitably form small particles. In addi- tion, conditions that yield a small RSS may

lead to a relatively stable

supersaturated solution that requires

a long time to fully precipitate. For example, almost a month is

required to form a visible

precipitate of BaSO4 under conditions in which the ini-

tial RSS is 5.

An increase in the time required to form a visible precipitate under conditions of low RSS is a consequence of both a slow rate of nucleation and a steady decrease

in RSS as the

precipitate forms. One

solution to the

latter problem is to chemically generate the precipitant in solution as the product

of a slow chemical reaction. This maintains the RSS at

an effectively constant level. The precipitate initially forms

under conditions of low RSS, leading to the nucleation of a limited

number of parti- cles. As additional precipitant is created, nucleation is eventually superseded by par- ticle growth.

This process is called homogeneous precipitation.

Two general methods

are used for

homogeneous precipitation. If the precipi- tate’s solubility is pH dependent, then the analyte

and precipitant can be mixed under conditions in which

precipitation does not occur. The pH is then raised

or lowered as needed by chemically generating OH– or

H3O+. For example,

the hydrol- ysis of urea can

be used as a source

of OH–.

CO(NH2)2(aq)+ H2O(l) < == == > CO2(g) + 2NH3(aq)

NH3(aq)+ H2O(l) < == == > NH4+(aq)+ OH–(aq)

The hydrolysis of urea is strongly temperature-dependent, with

the rate being

negli- gible at room temperature. The rate of hydrolysis, and thus the rate of precipitate

formation, can be controlled by adjusting the solution’s temperature. Precipitates of

BaCrO4, for example, have been produced in this manner.

In the second

method of homogeneous precipitation, the precipitant itself is generated by a chemical reaction. For example, Ba2+ can be homogeneously precipi- tated as BaSO4 by hydrolyzing sulphamic acid to produce

SO42–.

NH2SO3H(aq)+ 2H2O(l) < == == > NH4+(aq)+ H3O+(aq)+ SO42–(aq)

Homogeneous precipitation affords

the dual advantages of producing large particles of precipitate that are

relatively free from impurities. These advantages, however, may be offset

by increasing the time needed

to produce the precipitate,

and a tendency for the precipitate to deposit as a thin film on the container’s walls. The latter problem

is particularly severe for hydroxide

precipitates generated using urea.

An additional method

for increasing particle

size deserves mention.

When a precipitate’s particles are electrically neutral,

they tend to coagulate into larger par- ticles. Surface adsorption of excess lattice

ions, however, provides

the precipitate’s particles with a net positive or negative surface

charge. Electrostatic repulsion

be- tween the particles prevents them from

coagulating into larger

particles.

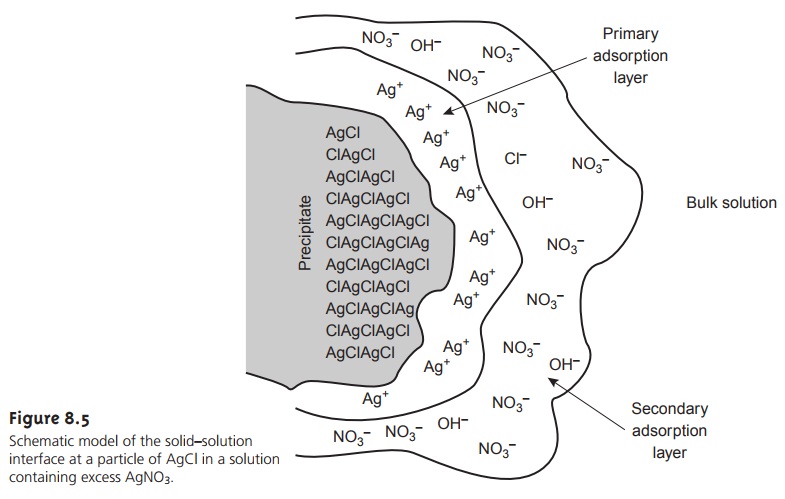

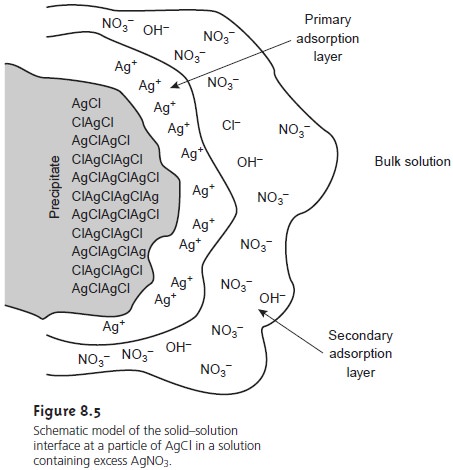

Consider, for instance,

the precipitation of AgCl from a solution

of AgNO3, using NaCl

as a precipitant. Early in the precipitation, when NaCl is the limiting reagent, excess Ag+ ions chemically adsorb to the AgCl

particles, forming a posi-

tively charged primary

adsorption layer (Figure

8.5). Anions in solution, in this case NO3– and OH–,

are attracted toward

the surface, forming

a negatively charged

sec- ondary adsorption layer that balances the surface’s positive

charge. The solution outside the secondary adsorption layer remains

electrically neutral. Coagulation cannot occur if the secondary adsorption layer is too thick because

the individual particles of AgCl are unable to approach one another closely

enough.

Coagulation can be induced in two ways: by increasing the concentration of the ions responsible for the secondary adsorption layer or by heating the solution. One way to induce coagulation is to add an inert electrolyte, which increases the concen- tration of ions in the secondary adsorption layer. With more ions available, the thickness of the secondary absorption layer decreases. Particles of precipitate may now approach one another more closely, allowing the precipitate to coagulate. The amount of electrolyte needed to cause spontaneous coagulation is called the critical coagulation concentration.

Heating the solution

and precipitate provides

a second way to induce

coagula- tion. As the temperature increases, the number of ions in the

primary adsorption layer decreases, lowering the precipitate’s surface charge. In addition, increasing the particle’s kinetic energy may be sufficient to overcome

the electrostatic repulsion preventing coagulation at lower temperatures.

Related Topics