Chapter: Modern Analytical Chemistry: Gravimetric Methods of Analysis

Theory and Practice of Precipitation Gravimetry: Filtering the Precipitate

Filtering the Precipitate

After precipitation and digestion are complete, the precip-

itate is separated from solution

by filtration using

either filter paper

or a filtering cru-

cible. The most common filtering

medium is cellulose-based filter paper, which is

classified according to its filtering speed, its size,

and its ash content on ignition. Fil- tering speed is a function of the paper’s

pore size, which

determines the particle sizes retained by the

filter. Filter paper

is rated as fast (retains particles > 20–25

μm), medium fast (retains

particles > 16 μm), medium

(retains particles >

8 μm), and slow

(retains particles > 2–3 μm). The proper

choice of filtering speed is important. If the filtering speed is too fast, the precipitate may pass through

the filter paper re-

sulting in a loss of precipitate. On the other

hand, the filter

paper can become

clogged when using

a filter paper

that is too slow.

Filter paper is hygroscopic and is not easily dried

to a constant weight. As a re- sult, in a quantitative procedure the filter paper must be removed

before weighing the precipitate. This is accomplished by carefully igniting

the filter paper.

Following ignition, a residue

of noncombustible inorganic ash remains that

contributes a posi- tive determinate error to the precipitate’s final mass. For quantitative analytical pro- cedures a low-ash

filter paper must be used.

This grade of filter paper

is pretreated by washing

with a mixture of HCl and HF to remove inorganic materials. Filter paper classed as quantitative has

an ash content

of less than

0.010% w/w. Qualita- tive filter paper typically has a maximum

ash content of 0.06% w/w.

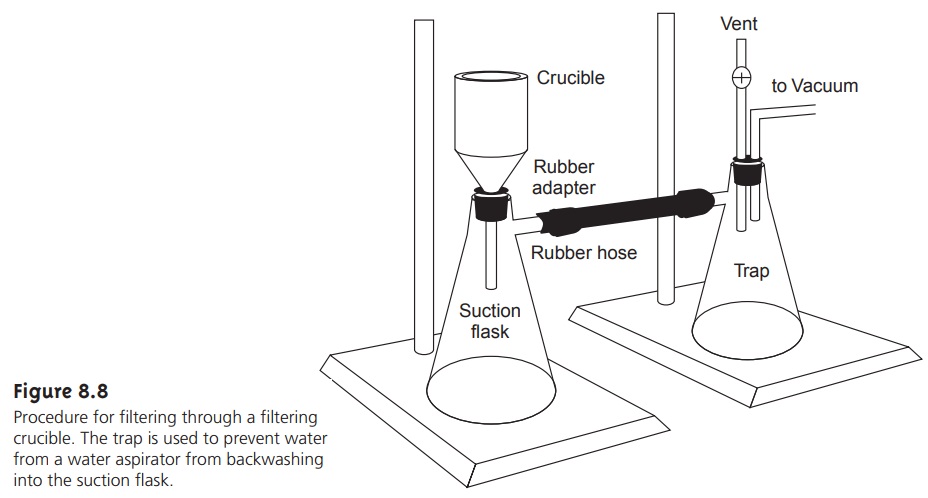

Filtering is accomplished by folding the

filter paper into

a cone, which

is then placed in a long-stem funnel (Figure 8.6).

A seal between the filter

cone and the funnel is formed by dampening the paper with water and pressing the paper to the

wall of the funnel. When

properly prepared, the

stem of the

funnel will fill

with the solution being

filtered, increasing the

rate of filtration. Filtration is accomplished by the force of gravity.

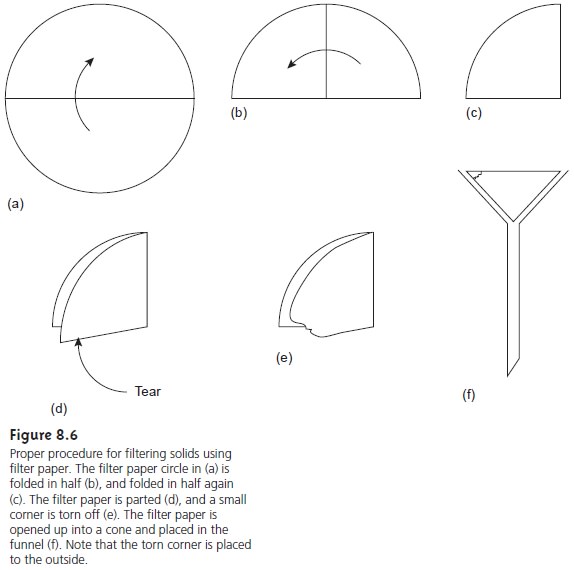

The precipitate is transferred to the filter in several

steps (Figure 8.7). The first step is to decant

the majority of the supernatant through the filter paper

without transferring the precipitate. This is done to prevent

the filter paper

from becoming clogged at the beginning of the filtration process. Initial rinsing

of the precipitate is done in the beaker

in which the precipitation was performed. These

rinsings are also decanted through the filter

paper. Finally, the

precipitate is transferred onto the filter paper

using a stream

of rinse solution. Any precipitate clinging

to the walls of the beaker

is transferred using

a rubber policeman (which is simply

a flexible rubber spatula attached to the end of a glass

stirring rod).

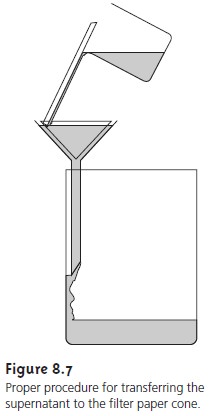

An alternative method

for filtering the

precipitate is a filtering crucible (Fig- ure 8.8). The most common

is a fritted glass crucible

containing a porous

glass disk filter. Fritted

glass crucibles are classified by their porosity:

coarse (retaining particles > 40–60 μm), medium (retaining particles > 10–15 μm), and fine (re- taining particles > 4–5.5

μm). Another type

of filtering crucible is the Gooch

cru- cible, a porcelain crucible with a perforated bottom.

A glass fiber

mat is placed in the crucible

to retain the precipitate, which

is transferred to the crucible

in the same manner

described for filter

paper. The supernatant is drawn through

the crucible with

the assistance of suction from

a vacuum aspirator or pump.

Related Topics