Chapter: Biotechnology Applying the Genetic Revolution: Pathway Engineering

Biosynthetic Plastics Are Also Biodegradable

BIOSYNTHETIC

PLASTICS ARE ALSO BIODEGRADABLE

Plastics are polymers built

from chains of monomer subunits, like proteins and nucleic acids. However, most

plastics consist of the same monomer mindlessly repeated over and over again.

Sometimes two or more closely related monomers may be mixed together and follow

each other at random.

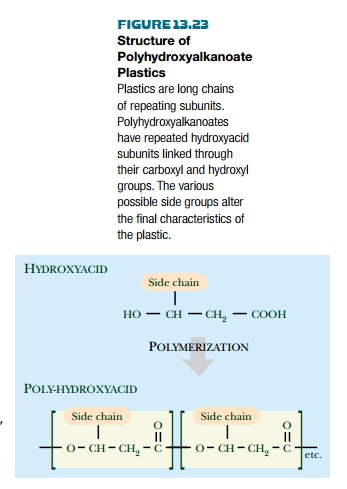

Certain bacteria make and

store a group of related plastics known as polyhydroxyalkanoates

(PHAs). Their composition is shown in Fig. 13.23. The bacteria accumulate

PHAs when they have surplus carbon and energy but are running low on other

essential nutrients, such as nitrogen or phosphorus. When conditions improve,

the PHA is broken down and used as a source of energy. The most commonly found

PHA has four-carbon (hydroxybutyrate, HB) subunits and is therefore called polyhydroxybutyrate (PHB). However, a

plastic made by randomly mixing in

10% to 20% of five-carbon (hydroxyvalerate, HV) subunits has much better

physical properties. Still other PHAs containing a proportion of subunits that

are eight-carbon or longer give materials that are more rubbery.

A poly-HB/HV copolymer is

manufactured by mutant bacteria of the species Alcaligenes eutrophus and is marketed by the Zeneca Corporation

(United Kingdom) under the trade name of Biopol. It is more expensive than

plastics made from oil, but it is completely biodegradable. Consequently, PHAs

are restricted at present to specialized uses. For example, because they break

down slowly inside the body to give natural, biochemical intermediates, they

can be used for making slow-release capsules.

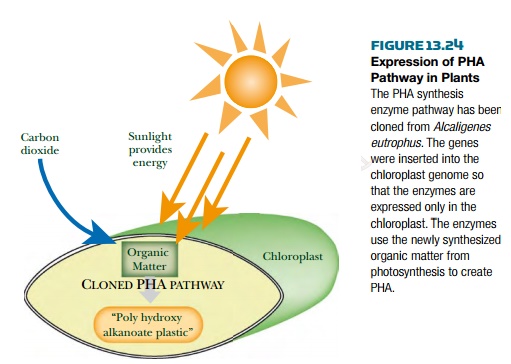

To make PHAs economically

competitive, they will need to be produced cheaply and in bulk. One possible

way to do this is to insert the genes for their synthesis into suitable crop Chloroplast plants. This is still in the

experimental stage, but the genes for making PHA from Alcaligenes eutrophus have been successfully inserted into Arabidopsis, a plant widely used for

genetic experiments. The engineered PHA genes were designed to be expressed

inside the chloroplasts of the plant (Fig. 13.24). Because chloroplasts are the

sites of photosynthesis, newly synthesized organic matter appears here first.

Locating the PHA pathway in chloroplasts, rather than in the main compartment

of the plant cells, gives a 100-fold increase in PHA yield. The next step will

be to move the pathway into a genuine crop plant such as rapeseed or soybeans.

Perhaps this will give new meaning to the phrase “plastic flowers”!

Related Topics