Chapter: Biotechnology Applying the Genetic Revolution: Pathway Engineering

Ethanol, Elephants, and Pathway Engineering

ETHANOL,

ELEPHANTS, AND PATHWAY ENGINEERING

Humans weren’t the first to

appreciate alcohol. Elephants, monkeys, and other wild animals deliberately

consume fruit that has naturally fermented, yielding alcohol. Indeed, elephants

in both Africa and Asia may run amok after consuming fermented fruit.

Occasionally, elephants will even raid local villages and knock over houses to

“recover” fermented liquids from their human competitors! There is even a

species of the fruit fly Drosophila,

from the sherry-producing regions of Spain, that relies on sherry as its sole

source of nutrition. These insects spend their lives circling around in the

caves where sherry is processed and presumably do not need to fly straight. The

earliest cultural remains from human alcohol consumption date to about 5000 B.C. Analysis of a yellowish

residue found in Neolithic pottery from Iran showed that it was derived from

wine.

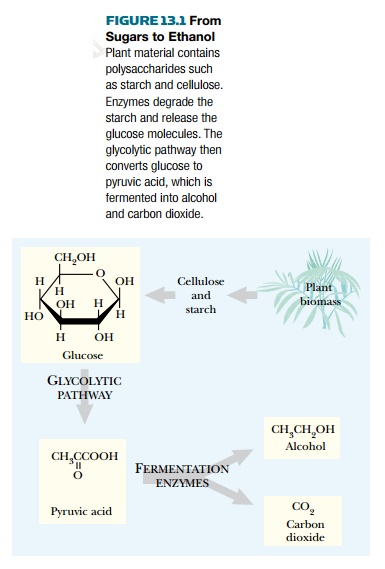

Alcohol is made from sugar

(Fig. 13.1). Sugars are components of the carbohydrates making up much of the

bulk of plant matter. So, in principle, alcohol can be made from almost any

plant-derived material. Yeast is used to ferment sugars derived from grain or

grapes, which produces an alcoholic liquid—the basis of beer or wine,

respectively. Distillation is then used to make concentrated liquors such as

whiskey or vodka. The lone exception to yeast is the use of a bacterium, Zymomonas, which ferments sugar from the

sap of the agave plant to give a liquid known as pulque. Distillation converts

this into tequila.

There is little need for

genetic engineering in the area of alcoholic drinks. However, alcohol may be

blended with gasoline to give “gasohol,” which works well in most internal combustion

engines. Thus conversion of waste biomass to fuel alcohol would not only get

rid of large amounts of waste material but would also reduce gasoline

consumption. If the United States converted the 100 million tons of waste paper

it generates each year into fuel-grade alcohol, this could replace 15% of the

gasoline used. Ethanol can also be made from corn, which is very economical

because many acres of corn are grown each year in the United States and a large

surplus is generated. Unlike wood pulp for paper, corn can be regenerated in 1

year.

The advantage of using Zymomonas and yeast is that they make

only alcohol during fermentation, whereas most microorganisms generate mixtures

of fermentation products. For example, Escherichia

coli makes a mixture of ethanol, acetate, succinate, lactate, and formate.

Although many fermentation products are potentially useful, purification is an

expensive drawback. The problem with Zymomonas

is that it lives entirely on glucose and lacks the enzymes to break down other

sugars, let alone those needed to degrade carbohydrate polymers such as starch

and cellulose. Yeast is almost as narrow in its growth requirements. Zymomonas grows faster than yeast and

makes alcohol faster as well. On the other hand, yeasts are more alcohol resistant and are therefore capable of

accumulating higher concentrations of ethanol in the medium before growth is

halted.

Genetic engineering is being

used to make improved strains of both yeast and Zymomonas that can use a wider range of sugars. In addition, genes

for enzymes capable of breaking down starch, cellulose, or other plant

polysaccharides can be inserted (see later discussion). Finally, these

organisms can also be engineered for improved resistance to alcohol or for

other properties that optimize growth and production under industrial

conditions.

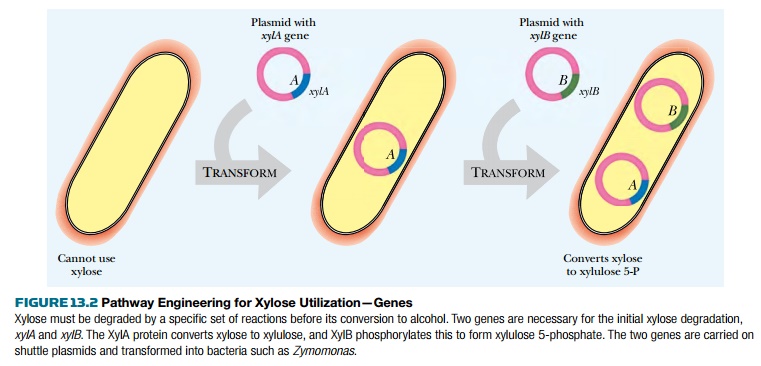

Xylose is a five-carbon sugar

that is a major component of various polysaccharides (xylans) found in plant

cell walls (see later discussion). Vast amounts of waste material from plants

are available for possible biodegradation. Breakdown of the polysaccharide

polymers would release large amounts of xylose. Consequently, it is worthwhile

to develop strains of Zymomonas that efficiently ferment xylose to ethanol.

This has been done in two stages. First

the genes for metabolism of xylose itself must be introduced, because Zymomonas

does not naturally use this sugar. The xylA and xylB genes encode the enzymes

xylose isomerase and xylulose kinase, respectively, which convert xylose to

xylulose and then to xylulose 5-phosphate. These two genes were placed on a

shuttle vector that carries replication origins for both E. coli, in which the

genetic engineering was done, and Zymomonas (Fig. 13.2).

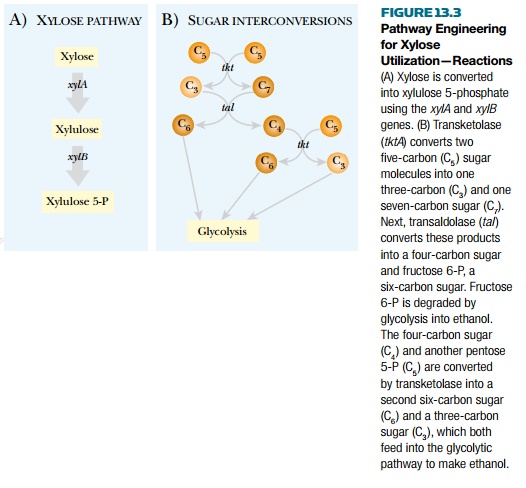

The strain with just the

extra xylAB genes grew poorly because

it accumulated xylulose 5-phosphate as well as the phosphates of other pentose

sugars, including ribose 5-phosphate. The genes for transketolase (tktA) and transaldolase (tal), two enzymes that convert pentose

phosphates back into hexose phosphates, were then included on the plasmid,

under control of a separate promoter. The resulting Zymomonas was then able to convert xylose first to xylulose

5-phosphate and then to fructose 6-phosphate and glyceraldehyde 3-phosphate.

Finally, these central intermediates were fermented efficiently to ethanol

(Fig. 13.3).

Related Topics