Chapter: Modern Analytical Chemistry: Obtaining and Preparing Samples for Analysis

The Importance of Sampling

The Importance of Sampling

When a manufacturer produces a chemical

they wish to list as ACS Reagent

Grade, they must demonstrate that it conforms

to specifications established by the Ameri- can Chemical Society (ACS). For

example, ACS specifications for NaHCO3 require that the concentration of iron be less than

or equal to 0.001% w/w.

To verify that

a production lot meets

this standard, the manufacturer performs

a quantitative analy- sis, reporting the result

on the product’s label. Because

it is impractical to analyze the entire production lot, its properties are estimated from a limited

sampling. Sev- eral samples are collected and analyzed, and the

resulting mean, X–, and standard de- viation, s, are used

to establish a confidence interval for the production lot’s true mean, μ

where n is the

number of samples, and t is a statistical factor

whose value is deter-

mined by the number of samples and

the desired confidence level.*

Selecting a sample

introduces a source

of determinate error

that cannot be cor-

rected during the

analysis. If a sample does

not accurately represent the population

from which it is drawn,

then an analysis

that is otherwise carefully conducted will yield inaccurate results. Sampling

errors are introduced whenever we extrapolate

from a sample to its target population. To minimize sampling

errors we must col-

lect the right sample.

Even when collecting the right sample,

indeterminate or random

errors in sam- pling may limit the usefulness of our results.

Equation 7.1 shows

that the width

of a confidence interval is directly proportional to the standard deviation.

The overall standard

deviation for an analysis, so, is determined by ran-

dom errors affecting each step

of the analysis. For convenience, we di-

vide the analysis into two steps. Random

errors introduced when collect-

ing samples are characterized by a standard

deviation for sampling, ss. The standard

deviation for the analytical method,

sm, accounts

for ran- dom errors

introduced when executing the method’s procedure. The re- lationship among

so, ss, and

sm is given by a propagation of random

error

Equation

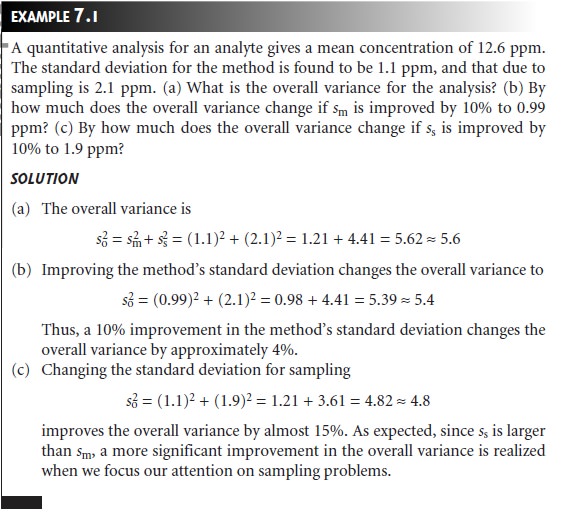

7.2 shows that an analysis’ overall variance may be lim-

ited by either

the analytical method or sample collection. Unfortu-

nately, analysts often attempt to minimize overall variance by im- proving

only the method’s precision. This is futile, however, if the standard

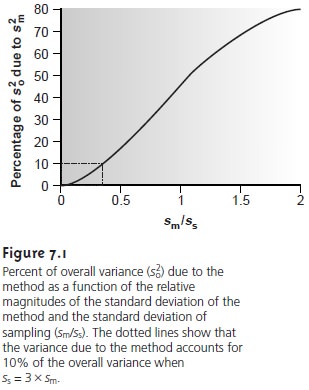

deviation for sampling is more than three times greater than that for the method. Figure 7.1 shows how the ratio sm/ss affects the percentage

of overall variance attributable to the method. When the method’s

standard deviation is one third of that for sampling, indeterminate method errors explain only 10% of the overall variance.

Attempting to improve the analysis by decreasing sm provides

only a nominal

change in the overall variance.

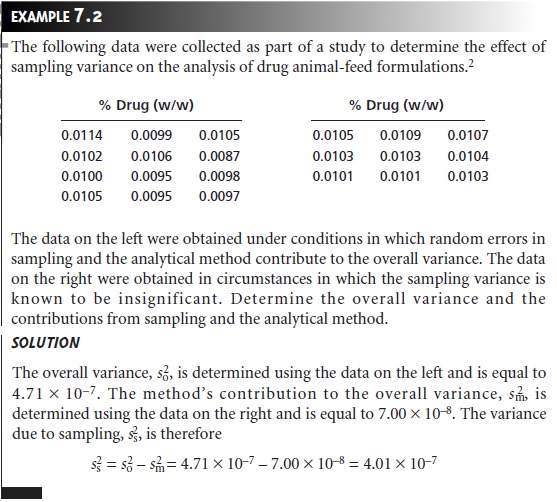

To determine which

step has the greatest effect

on the overall variance, both sm2

and s2 must

be known. The analysis of replicate samples

can be used to estimate

the overall variance. The variance due to the method is determined by analyzing a stan-

dard sample, for which we may assume

a negligible sampling variance. The variance due to sampling is then determined by difference.

Related Topics