Chapter: Modern Analytical Chemistry: Obtaining and Preparing Samples for Analysis

Classifying Separation Techniques: Separations Based on a Partitioning Between Phases

Separations Based on a Partitioning Between

Phases

The

most important class

of separation techniques is based on the selective parti- tioning of the analyte or interferent between

two immiscible phases.

When a phase containing a solute,

S, is brought into

contact with a second phase,

the solute parti- tions itself between the two phases.

7.18

7.18

is

called the distribution constant, or partition coefficient. If KD is sufficiently large, then the solute will move from phase 1 to phase

2. The solute will remain

in phase 1, however, if the partition coefficient is sufficiently small. If a phase containing two solutes is brought

into contact with

a second phase,

and KD is favorable for only one of

the solutes, then

a separation of the solutes

may be possible. The physical states

of the two phases

are identified when describing the separation process,

with the phase containing the sample listed

first. For example,

when the sample

is in a liquid phase and the second phase

is a solid, the separation involves liquid–solid partitioning.

Extraction Between Two Phases

When the

sample is initially present in one

of the phases, the separation is known as an extraction. In a simple extraction the sample

is extracted one or more times with portions of the second

phase. Simple extrac- tions are particularly useful for separations in which only one component

has a fa- vorable distribution ratio. Several important separation

techniques are based on simple extractions, including

liquid–liquid, liquid–solid, solid–liquid, and gas–solid

extractions.

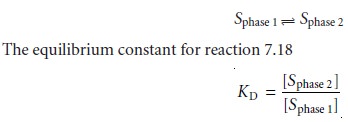

Liquid–Liquid Extractions

Liquid–liquid extractions are usually

accomplished with a separatory funnel

(Figure 7.15). The

two liquids are

placed in the

separa- tory funnel and shaken to increase the surface area between the phases. When the

extraction is complete, the liquids

are allowed to separate, with the denser

phase settling to the bottom of the separatory funnel. Liquid–liquid extractions also may be carried out

in the sample

container by adding

the extracting solvent

when the sample is collected. Pesticides in water, for example, may be preserved for longer periods

by extracting into

a small volume

of hexane added

to the sample

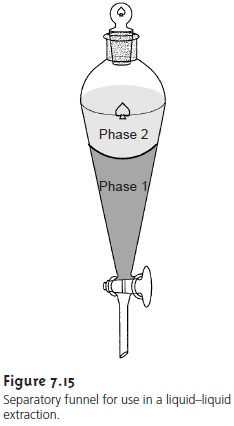

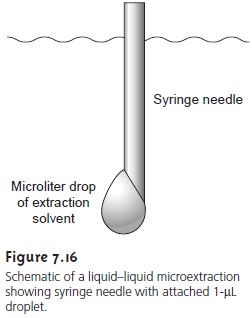

in the field. Liquid–liquid microextractions, in which

the extracting phase

is a 1-ÎĽL drop suspended from a microsyringe (Figure 7.16) also have been described.

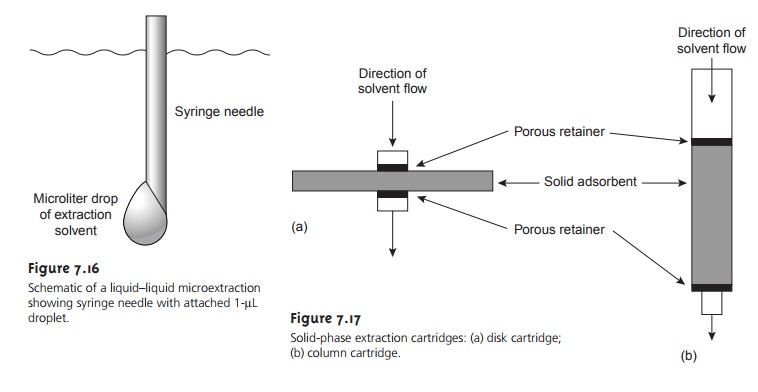

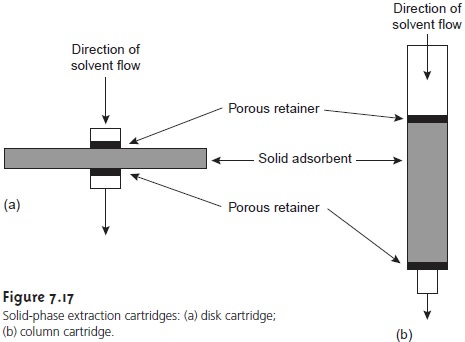

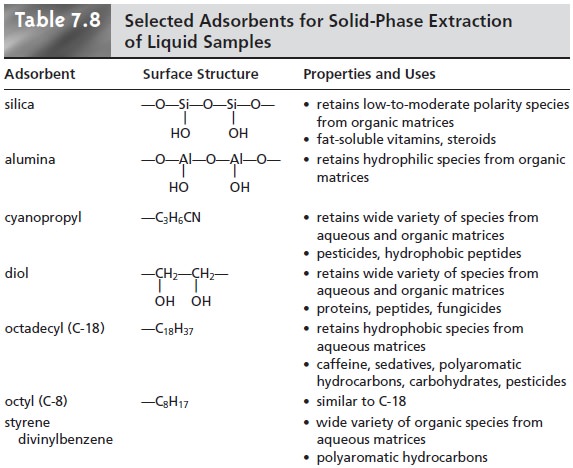

Solid-Phase Extractions

In a solid-phase extraction the sample is passed through a cartridge containing solid particulates that serve as the adsorbent material. For liq- uid samples the solid adsorbent is isolated in either a disk cartridge or a column (Figure 7.17). The choice of adsorbent is determined by the properties of the species being retained and the matrix in which it is found. Representative solid adsorbents are listed in Table 7.8.

For example, sedatives, such as secobarbital and phenobarbi-

tal, can be isolated from

serum by a solid-phase extraction using a C-18

solid adsor- bent. Typically a 500-ÎĽL sample

of serum is passed through

the cartridge, with the

sedatives being retained

by a liquid–solid extraction. The cartridge is then washed with distilled water to remove any residual traces

of the serum’s matrix. Finally,

the retained sedatives are eluted from the cartridge by a solid–liquid

extraction using 500 ÎĽL of acetone.

For many analyses, solid–phase extractions are replacing

liquid–liquid extractions due to their

ease of use, faster extraction times, decreased

volumes of solvent, and their superior ability

to concentrate the analytes.

Solid-phase microextractions also

have been developed. In one approach, a fused silica fiber is placed inside a syringe needle.

The fiber, which is coated with a thin

organic film, such as poly(dimethyl siloxane), is lowered

into the sample

by de- pressing a plunger and exposed to the sample for a predetermined time. The fiber is

then

withdrawn into the needle and transferred to a gas chromatograph for analysis.

In gas–solid extractions the sample is passed through

a container packed

with a solid adsorbent. One example of the application of gas–solid extraction is in the analysis of organic compounds for carbon and hydrogen. The sample is combusted

in a flowing stream of O2, and

the gaseous combustion products are passed

through a series of solid-phase adsorbents that remove the CO2 and H2O.

Continuous Extractions

An extraction is still feasible even when the component of interest has an unfavorable partition coefficient, provided that all other components in the sample have significantly smaller partition coefficients.

Because the partition coefficient is unfavorable, a simple extraction will not be quantitative. Instead,

the extraction is accomplished by continuously passing

the extracting phase

through the sample until

a quantitative extraction is achieved.

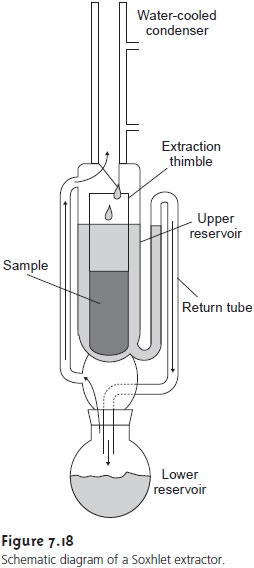

Many continuous extractions involving solid samples

are carried out with a Soxhlet extractor (Figure 7.18). The extracting solvent is placed in the lower reser- voir and heated to its boiling

point. Solvent in the vapor phase moves upward through the tube on the left side of the apparatus to the condenser where it con- denses back to the liquid state.

The solvent then passes through

the sample, which is

held in a porous cellulose filter thimble, collecting in the upper

reservoir. When the volume

of solvent in the upper

reservoir reaches the

upper bend of the return tube, the solvent and any extracted components are siphoned

back to the lower

reservoir. Over time,

the concentration of the extracted component in the lower

reservoir increases.

Soxhlet extractions have been replaced

in some applications by microwave-

assisted extractions.

The process is the same

as that described earlier for microwave digestion. The sample is placed in a sealed

digestion vessel along

with the liquid

ex- traction phase, and a microwave

oven is used to heat the extraction mixture. Using a sealed

digestion vessel allows

the extraction to take place

at a higher temperature

and pressure, thereby reducing the amount of time needed

for a quantitative extrac-

tion. In a Soxhlet extraction the temperature is limited by the solvent’s boiling point at atmospheric pressure. For example,

when acetone is the solvent,

a Soxhlet extrac- tion is limited to 56 °C. With a microwave-assisted extraction, however, a tempera- ture of over 150

°C can be obtained when

using acetone as the solvent.

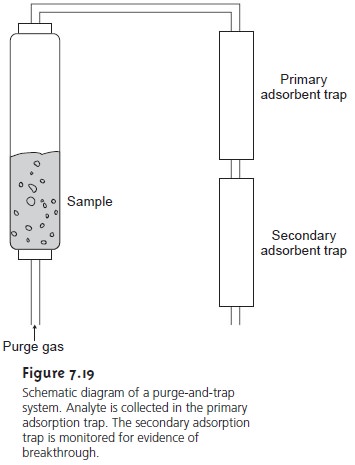

Two

other examples of a continuous extraction deserve mention.

Volatile or- ganic compounds (VOCs) can be quantitatively removed

from liquid samples

by a liquid–gas extraction. As shown in Figure 7.19,

the VOCs are removed by passing

an inert purging gas, such as He, through the sample. The He removes

the VOCs, which are then carried

by the He to a tube where

they are collected on a solid

adsor- bent. When the extraction is complete, the VOCs can then be removed from the

trap for analysis by rapidly

heating the tube while flushing

with He. This technique

is known as a purge and trap. Recoveries for analytes using

a purge and

trap may not be reproducible, requiring the use of internal standards for quantitative work.

Continuous extractions also can be accomplished with supercritical fluids.19 When a substance is heated above

its critical temperature and pressure, it forms a supercritical fluid whose properties are between those

of a gas and a liquid. Super- critical fluids are better solvents than gases, making them a better reagent

for ex- tractions. In addition, the viscosity of a supercritical fluid is significantly less than that of a liquid

solvent, allowing it to pass

more readily through

particulate samples. One example

of a supercritical extraction is the determination of total petroleum hydrocarbons (TPHs) in soils,

sediments, and sludges with supercritical CO2. Approximately 3 g of sample is placed in a 10-mL stainless steel cartridge, and super-

critical CO2, at a pressure

of 340 atm and a temperature of 80 °C, is passed

through the cartridge for

30 min at flow rate

of 1–2 mL/min.

The petroleum hydrocarbons are collected by passing

the effluent from the cartridge through 3 mL of tetra-

chloroethylene at room temperature. At this temperature the CO2 reverts

to the gas phase and is released to the atmosphere.

Chromatographic Separations

In

an extraction, the

sample is initially present in one phase,

and the component of interest is extracted into a second

phase. Separa- tions can

also be accomplished by continuously passing

one sample-free phase, called the mobile phase,

over a second sample-free phase

that remains fixed

or sta- tionary. The

sample is then

injected or placed

into the mobile

phase. As the

sam- ple’s components move with the mobile phase, they partition

themselves between the mobile and stationary phases. Those components having the largest

partition coefficients are more likely to move into the stationary phase, taking longer to pass through the system. This is the basis of all chromatographic separation techniques.

As currently practiced, modern chromatography provides a means

both of separat- ing analytes and interferents and of performing a qualitative or quantitative analysis of the analyte.

Related Topics