Chapter: Modern Analytical Chemistry: Obtaining and Preparing Samples for Analysis

Implementing the Sampling Plan: Solids

Solids

Typical examples of solid samples include large particulates, such as those found in ores; smaller particulates, such as soils and sediments; tablets, pellets, and capsules used in dispensing pharmaceutical products and animal feeds; sheet materials, such as polymers and rolled metals; and tissue samples from biological specimens.

Sample Collection

Solids

are

usually

heteroge- neous, and

samples must be collected carefully if they are to be representative of the target

popula- tion. As noted

earlier, solids come

in a variety of forms, each

of which is sampled differently.

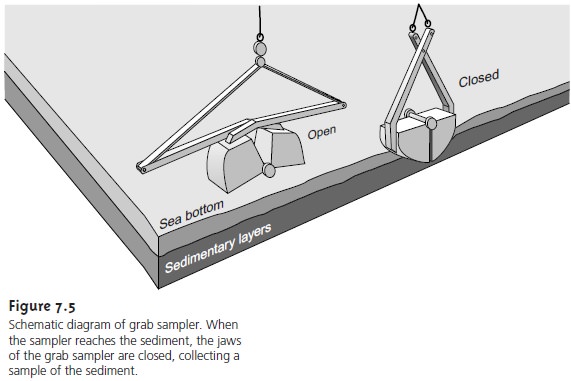

Sediments from the bottom of streams, rivers, lakes, estuaries, and oceans are collected with a bot- tom

grab sampler or with a corer. Grab samplers are equipped with a pair of “jaws”

that close when they

contact the sediment, scooping up sediment in

the

|

|

Disadvantages include the tendency

to lose finer- grained sediment

particles as water flows out of the sampler and the loss of spatial

information, both lat erally and with depth,

due to mixing

of the sample.

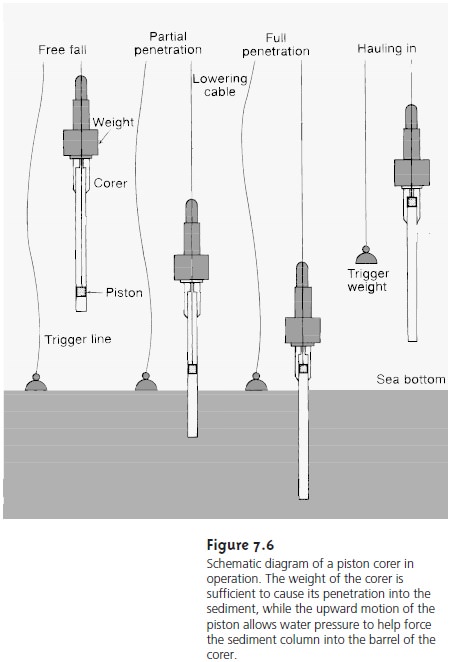

An alternative method for sampling sediments uses a cylindrical coring device (Figure

7.6). The corer is dropped into the sediment, collecting a col- umn of sediment and the water in

contact with the sediment. With the possible exception of sediment at the surface,

which may experience mixing, sam-ples collected with a corer

maintain their vertica profile. As a result,

changes in the sediment’s com- position with depth are preserved. The main disad- vantage to a corer

is that only

a small surface

area is sampled. For

this reason sampling with a corer

usu- ally requires more samples.

Soil

samples

collected at

depths

of

up

to

30

cm

are

easily

collected with scoops or shovels, although the sampling variance is generally high. A better

method for obtaining

soil samples near the surface

is to use a soil punch. This thin-walled steel tube retains

a core sample when it is pushed

into the soil and removed. Soil samples collected at depths greater

than 30 cm are obtained

by digging a trench and

collecting lateral samples

with a soil

punch. Alternatively, an auger may be used to drill a hole to the desired

depth and the sample col- lected with a soil punch.

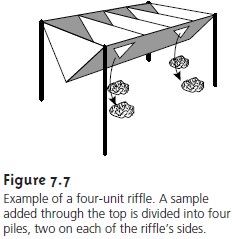

The sampling of particulate material

is often determined by the size of the par-

ticles. Large particulate solids, such as coals and

ores, can be sampled by randomly

collecting samples with a shovel

or by riffling. A riffle

(Figure 7.7) is a trough

con- taining an even number of compartments with adjacent compartments

emptying on opposite sides

of the riffle.

Particulate material dumped

into a riffle

is divided into two parts. By repeatedly passing

half of the separated material

back through the riffle, a sample of any desired

size may be collected. Smaller

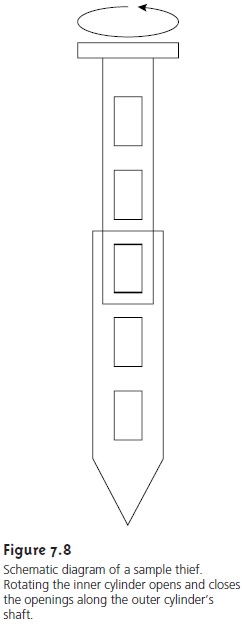

particulate materials, such as powders, are best collected

with a sample thief, which allows material

to be collected simultaneously from several locations (Figure 7.8). A typical sample

thief consists of two tubes that are nestled

together. Each tube has an identical set of slots aligned down their length.

Before the sample

thief is inserted into the material being sampled, the inner

tube is rotated

so that slots

are closed. When the sample

thief is in place, the inner tube is rotated to open the slots, allowing

the powder to enter the sample thief through each slot. The inner tube is then rotated to the closed position

and the sample thief withdrawn.

When sampling a metal, it usually is necessary to obtain material

from both the surface and the interior. When the metal

is in the form of a sheet,

random samples can be collected with a metal punch. Samples

can be obtained from a metal wire by

randomly cutting off pieces of an appropriate length. Larger pieces

of metal, such as

bars or bricks, are best sampled by sawing through

the metal at randomly selected points and collecting the “sawdust” or by drilling

through the metal and collecting the shavings. A surface

coating can be sampled in situ or by dissolving the coating with an appropriate solvent.

Sampling of biological tissue is done

by removing the

entire organ, which

is then homogenized before

smaller portions are

taken for analysis. Alternatively, sev-

eral small portions of tissue

may be combined to form a composite sample. The

composite sample is then homogenized and analyzed.

Sample Preservation

Without preservation, many solid samples

are subject to changes in chemical composition due to the

loss of volatile material, biodegrada-

tion, and chemical reactivity (particularly redox reactions). Samples stored at

re- duced temperatures are less prone

to biodegradation and the loss of volatile

mate- rial, but fracturing and phase separations may present problems. The loss of volatile

material is minimized by ensuring

that the sample

completely fills its container

without leaving a headspace where gases can collect. Samples

collected from mate- rials that have not

been exposed to O2 are particularly susceptible to oxidation reac- tions. For example, the contact of air with anaerobic sediments must be prevented.

Sample Preparation

Unlike

gases

and liquids,

which generally require little sample

preparation, solid samples

usually need some processing before analysis. There are two reasons for this. First,

as discussed, sampling

variance is a function of the number of particles

sampled, not their combined

mass. For extremely

heteroge- neous populations consisting of large particulates, the gross sample

may be too large to analyze. For example,

a boxcar containing a load of a Ni-bearing ore with an average

particle size of 5 mm may

require a sample

weighing one

ton to obtain a reasonable sampling variance. Reducing the

sample’s average particle size allows the

same number of particles to be sampled with a smaller,

more manageable combined mass.

Second, the majority of analytical techniques, particularly those used for a quantitative analysis, require that the analyte be in solution. Solid samples, or at least the analytes in a solid sample, must be brought into solution.

Reducing Particle Size

A reduction in particle size

is accomplished by a combina- tion of crushing and grinding the gross sample.

The resulting particulates are then thoroughly mixed and divided

into samples of smaller mass containing the appro-

priate number of particles. The

process seldom occurs

in a single step. Instead, sam- ples are cycled

through the process

several times until

a laboratory sample of

de- sired mass is obtained.

Crushing and grinding

uses mechanical force

to break larger

particles into smaller ones.

A variety of tools are

used depending on the particle’s size and hard- ness. Large particles are

crushed using jaw

crushers capable of reducing particles to diameters of a few millimeters. Ball mills, disk

mills, and mortars

and pestles are used to further reduce

particle size.

Significant changes in composition may occur during crushing and grinding. Decreasing particle size

increases available surface area. With more surface area there is a greater

risk of losing

volatile components, a problem made worse by the

frictional heat accompanying the crushing and grinding. An increase in surface area also means that portions of the sample

are freshly exposed

to the atmosphere where oxidation may alter

the sample’s composition. Other problems include

contamina- tion from the

mechanical abrasion of the materials used to crush

and grind the sample, and differences in the ease with which particles are reduced in size. Softer particles are reduced in size more easily and may be lost as dust before

the rest of the

sample has been processed. This is a problem since

the analyte’s distribution may not be uniform

between particles of different size.

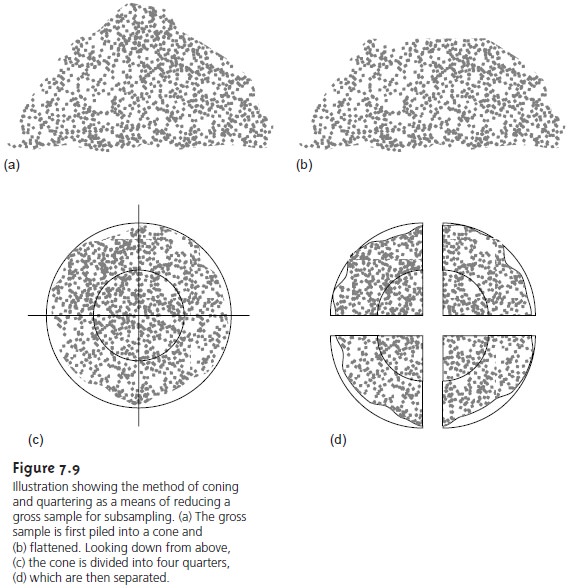

To ensure that all particles are reduced to a uniform size, the sample is intermit- tently passed through a sieve. Processing of those particles not passing through the sieve continues until the entire sample is of uniform size. The sample is then mixed thoroughly to ensure homogeneity, and a secondary sample obtained with a riffle or by coning and quartering. The latter approach is outlined in Figure 7.9. The gross sample is piled into a cone, flattened, divided into four quarters, and two diagonally opposed quarters are discarded. The remaining material is cycled through the process of coning and quartering until the desired amount of sample remains.

Bringing Solid Samples into Solution

If you

are fortunate, the

sample with which you are working will easily dissolve

in a suitable solvent, requiring no more effort than gentle swirling and heating. Distilled water is usually

the solvent of choice for inorganic salts, but an organic solvent, such as methanol, chloroform, or toluene, is used for organic

materials. More often, one or more of the sample’s

components re- sist simple dissolution.

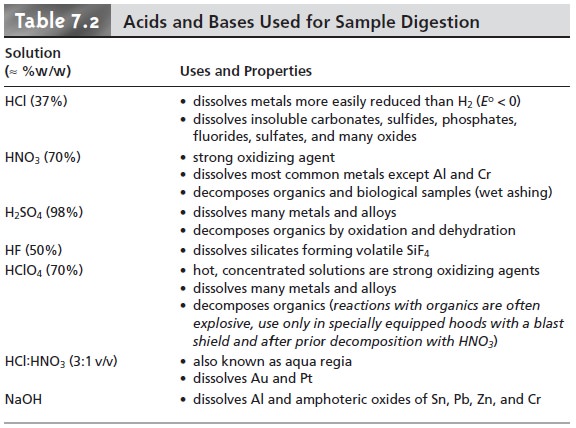

With samples that

are difficult to dissolve, the

first approach is usually to try di- gesting the sample with

an acid or base. Table

7.2 lists the

most commonly used acids and bases and

summarizes their use.

Digestion is commonly carried out in an

open container, such as a beaker, using

a hot plate as a source of heat. The chief ad- vantage of this approach

is its low cost as it requires

no special equipment. Volatile reaction products, however,

are lost, leading

to a determinate error if analyte is in-

cluded among the volatile substances.

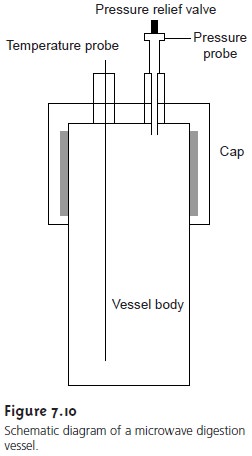

Many digestions are now carried out in closed containers using microwave ra- diation as a source of energy for heating the solution. Vessels for microwave diges- tion are manufactured using Teflon (or some other fluoropolymer) or fused silica. Both materials are thermally stable, chemically resistant, transparent to microwave radiation, and capable of withstanding elevated pressures. A typical microwave digestion vessel is shown in Figure 7.10 and consists of the vessel body and cap, a tem- perature probe, and a pressure relief valve. Vessels are placed in a microwave oven (typically 6–12 vessels can be accommodated), and microwave energy is controlled by monitoring the temperature or pressure within the vessels. A microwave diges- tion has several important advantages over an open container digestion, including higher temperatures (200–300 °C) and pressures (40–100 bar). As a result, diges- tions requiring several hours in an open container may be accomplished in less than 30 min using microwave digestion.

In addition, the closed

container prevents the loss of volatile

gases. Disadvantages include

the inability to add reagents

during di- gestion, limitations on the amount of sample that can be used (typically 1 g or less),

and safety concerns due to the use of high pressures and corrosive reagents. Appli- cations include environmental and biological samples.

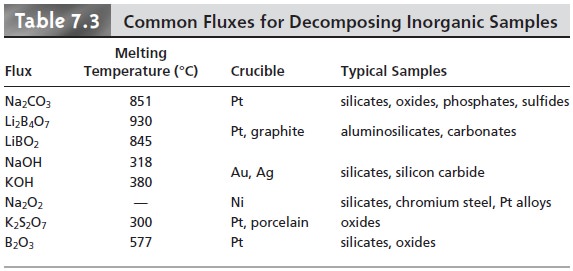

Inorganic samples that resist decomposition by digestion with acids or

bases

often

can be brought into solution by fusing

with a large excess

of an al- kali metal salt, called a flux. The sample and flux are mixed together

in a cru- cible and heated till the substances

fuse together in a molten state. The resulting melt is allowed

to cool slowly to room temperature. Typically the melt dissolves readily in distilled

water or dilute acid. Several

common fluxes and their uses are

listed in Table 7.3. Fusion works when other methods

of decomposition do not because

of the higher temperatures obtained and the high concentration of the reactive flux in the molten liquid. Disadvantages include a greater risk of contamination from the large quantity

of flux and the crucible

and the loss of volatile

materials.

Finally, organic materials may be decomposed by dry ashing.

In this method the sample is placed

in a suitable crucible and heated over a flame

or in a furnace. Any carbon present in the sample is oxidized

to CO2, and hydrogen, sulfur,

and ni- trogen are removed as H2O, SO2 and N2. These

gases can be trapped and weighed to determine their content in the organic

material. Often the

goal of dry

ashing is the removal of organic material, leaving behind an inorganic residue, or ash, that

can be further analyzed.

Related Topics