Chapter: Modern Analytical Chemistry: Obtaining and Preparing Samples for Analysis

LiquidŌĆōLiquid Extractions

LiquidŌĆōLiquid

Extractions

A liquidŌĆōliquid extraction is one of the most important separation techniques used in environmental, clinical, and industrial laboratories. Two examples from envi-

ronmental analysis serve

to illustrate its

importance. Public drinking water supplies are routinely monitored for trihalomethanes (CHCl3, CHBrCl2, CHBr2Cl, and CHBr3) because

of their known or suspected

carcinogeneity. Before their analysis

by gas chromatography, trihalomethanes are separated from their aqueous

matrix by a liquidŌĆōliquid extraction using pentane.21 A liquidŌĆōliquid extraction is also used in screening orange

juice for the

presence of organophosphorous pesticides. A

sample of orange juice is mixed with acetonitrite and filtered. Any organophospho-

rous pesticides that

might be present

in the filtrate are extracted with

petroleum ether before a gas chromatographic analysis.22

In

a simple liquidŌĆōliquid extraction the solute

is partitioned between

two im- miscible phases.

In most cases

one of the phases is aqueous, and the other

phase is an organic

solvent such as diethyl ether

or chloroform. Because

the phases are im-

miscible, they form two layers,

with the denser

phase on the bottom. The solute is initially present in one phase, but after extraction it is present

in both phases. The efficiency of a liquidŌĆōliquid extraction is determined by the equilibrium constant for the soluteŌĆÖs

partitioning between the two phases.

Extraction efficiency is also in- fluenced by any secondary reactions involving the solute. Examples

of secondary re- actions include acidŌĆōbase and

complexation equilibria.

Partition Coefficients and Distribution Ratios

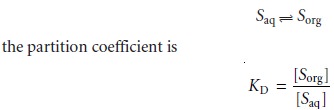

Earlier we learned that the partitioning of a solute between two phases is described

by a partition coefficient. If the solute

is initially in an aqueous

phase and is ex-

tracted into an organic phase*

A large value

for KD indicates that

the extraction of the solute

into the organic

phase is favorable.

In

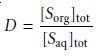

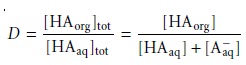

evaluating the efficiency of an extraction, however, we must consider the soluteŌĆÖs total concentration in each phase.

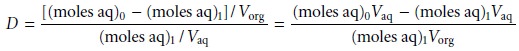

We define the distribution ratio, D, to

be the ratio of the

soluteŌĆÖs total concentration in each phase.

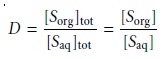

When the solute exists in only one form in each phase, then the partition

coefficient and the distribution ratio are identical. If, however, the solute exists

in more than one

form in either phase, then KD and D usually have different values.

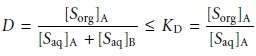

For example, if the

solute exists in two forms

in the aqueous

phase, A and

B, only one

of which, A, partitions itself between the

two phases, then

This distinction between

KD and D is important. The partition coefficient is an equilibrium constant

and has a fixed value

for the soluteŌĆÖs

partitioning between the two

phases. The value

of the distribution ratio, however,

changes with solution

con- ditions if the

relative amounts of forms A and B change. If we know

the equilibrium reactions taking place within each phase and between

the phases, we can derive an

algebraic relationship between

KD and D.

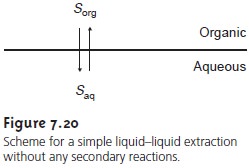

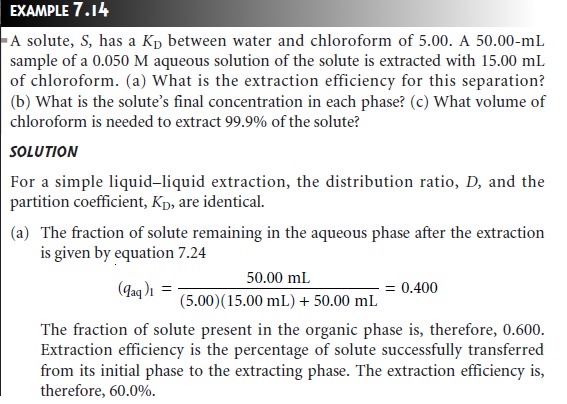

LiquidŌĆōLiquid Extraction with No Secondary Reactions

In the simplest form of

liquidŌĆōliquid extraction, the only reaction affecting extrac- tion efficiency, is the partitioning of the solute

between the two phases (Figure

7.20). In this case

the distribution ratio

and the partition coefficient are equal.

7.19

7.19

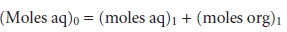

Conservation of mass requires

that the moles

of solute initially present in one phase equal the combined

moles of solute

in the aqueous and organic

phases after the extraction; thus

7.20

7.20

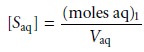

where the subscript indicates the extraction number. The concentration of S in the aqueous phase after the

extraction is

7.21

7.21

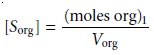

whereas the soluteŌĆÖs concentration in the organic

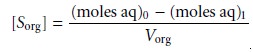

phase is

7.22

7.22

where Vaq and Vorg are the volumes

of the aqueous and organic

phases. Solving equation 7.20 for (moles

org)1 and substituting into equation 7.22 leave us with

7.23

7.23

Substituting equations 7.21 and 7.23

into equation 7.19, we obtain

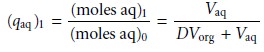

Rearranging and solving for the fraction

of solute remaining

in the aqueous phase after one extraction, (qaq)1, gives

7.24

7.24

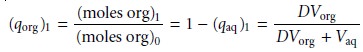

The fraction present in the organic

phase after one extraction, (qorg)1,

is

The fraction present in the organic

phase after one extraction, (qorg)1,

is

Example 7.14 shows how equation 7.24 is used to calculate the efficiency of a simple liquidŌĆōliquid extraction.

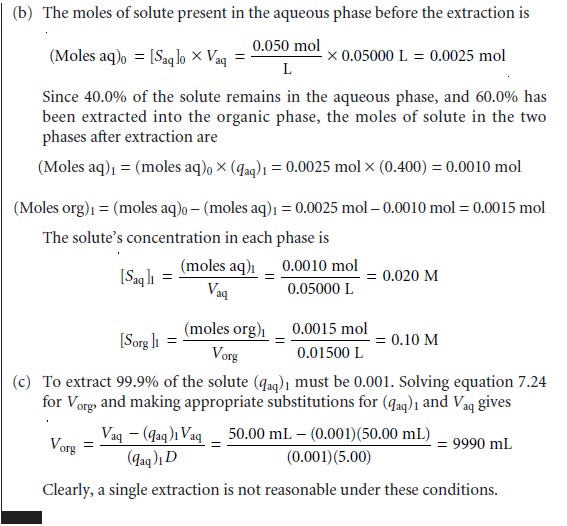

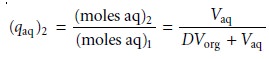

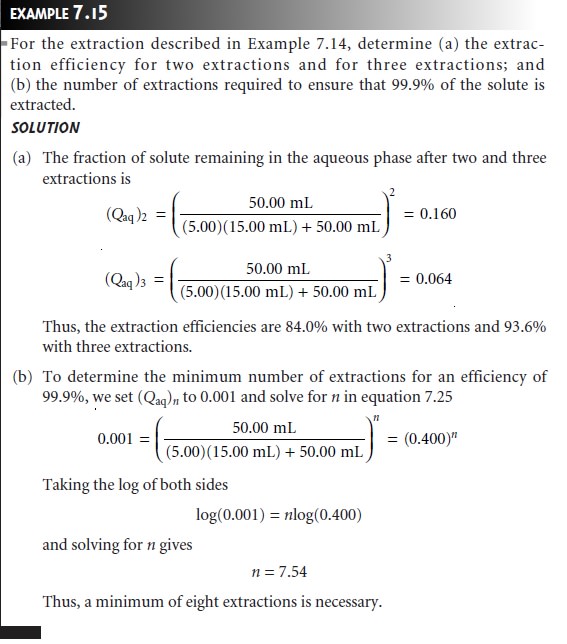

In

Example 7.14 a single extraction results in an extraction efficiency of only 60%. If a second

extraction is carried

out, the fraction

of solute remaining in the aqueous phase,

(qaq)2, is given by

If

the volumes of the aqueous

and organic layers are the same for both extractions, then the cumulative fraction

of solute remaining

in the aqueous layer after two ex- tractions, (Qaq)2, is

In

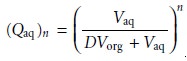

general, for a series of n identical extractions, the fraction of analyte remaining in the aqueous phase

after the last extraction is

7.25

7.25

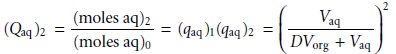

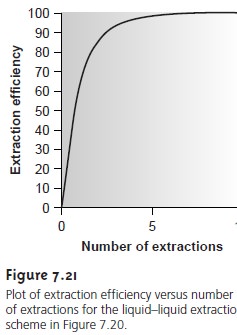

An important observation from Examples 7.14

and 7.15 is that an extraction

efficiency of 99.9%

can be obtained with less solvent

when using multiple extrac- tions. Obtaining this extraction efficiency with one extraction requires 9990 mL of

the organic solvent.

Eight extractions using

separate 15-mL portions

of the or- ganic solvent, however, requires only 120

mL. Although extraction efficiency in-

creases dramatically with the first

few multiple extractions, the effect quickly

di- minishes as the number

of extractions is increased (Figure

7.21). In most cases

there is little gain in extraction efficiency after five or six extractions. In Example 7.15 five extractions are needed to reach an extraction efficiency of 99%, and

an additional three extractions are required to obtain the

extra 0.9% increase in ex- traction

efficiency.

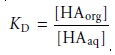

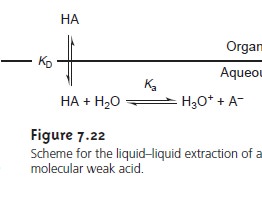

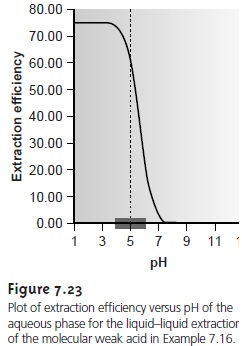

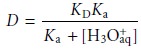

LiquidŌĆōLiquid Extractions Involving AcidŌĆōBase Equilibria

In a simple

liquidŌĆōliquid extraction the distribution ratio

and the partition coeffi- cient are identical. As a result,

the distribution ratio

is unaffected by any change

in the composition of the aqueous

or organic phase.

If the solute

also partici- pates in a single-phase equilibrium reaction, then the

distribution ratio and the partition coefficient may not be the same. For example, Figure 7.22

shows the equilibria occurring when extracting an aqueous solution

contain- ing a molecular weak acid, HA,

with an organic

phase in which

ionic species are not soluble. In this case the partition

coefficient and the distribution ratio are

7.26

7.26

7.27

7.27

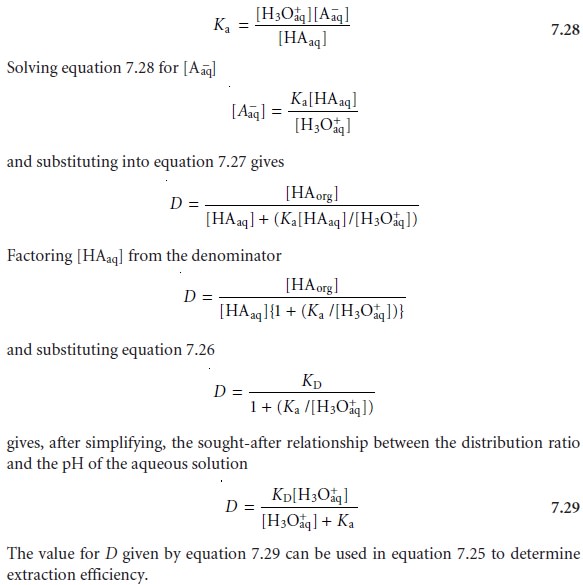

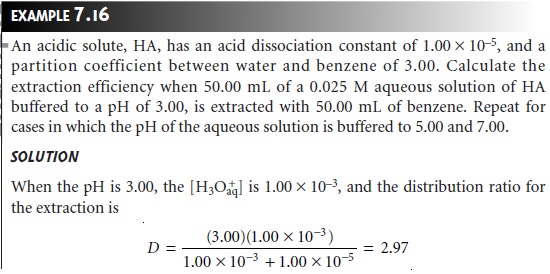

Since the position of an acidŌĆōbase equilibrium depends on the pH, the distribution ratio must also be pH-dependent. To derive an equation for D showing this depen-

dency, we begin with the

acid dissociation constant for HA.

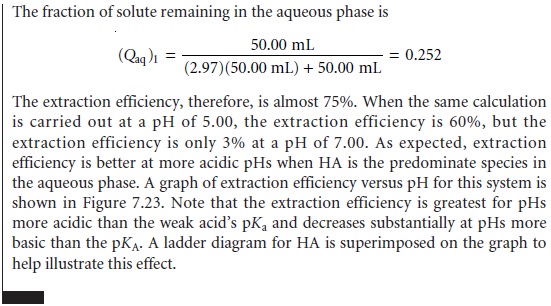

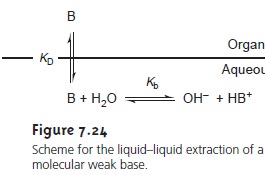

The same approach

can be used to derive an equation

for the distri- bution ratio when the solute is a molecular weak base, B, (Figure 7.24). The resulting distribution ratio

is

where Ka is the acid dissociation constant

for the weak baseŌĆÖs conjugate weak acid.

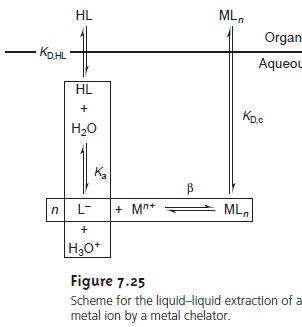

LiquidŌĆōLiquid Extractions Involving Metal Chelators

One

of the most common applications of a liquidŌĆōliquid extraction is the selective extraction of metal ions using a chelating agent. Unfor- tunately,

many chelating agents have a limited

solubility in water or are subject

to hydrolysis or air oxidation

in aqueous solutions.

For these reasons

the chelating agent is added to the organic solvent in- stead

of the aqueous phase. The

chelating agent is extracted

into the aqueous phase, where it reacts to form a stable metalŌĆōligand complex with the metal ion. The metalŌĆōligand complex is then extracted

into the organic phase. A summary

of the relevant equilibria is shown in Figure 7.25.

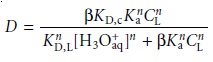

If

the ligandŌĆÖs concentration is much greater

than the metal

ionŌĆÖs concentration, the distribution ratio is given

as*

7.30

7.30

where CL is the initial

concentration of ligand

in the organic phase be- fore

the extraction. The distribution ratio

calculated using equation

7.30 can be substituted back into equation

7.25 to determine the extraction efficiency. As shown in Example 7.17, the extraction efficiency for metal ions shows a marked

pH dependency.

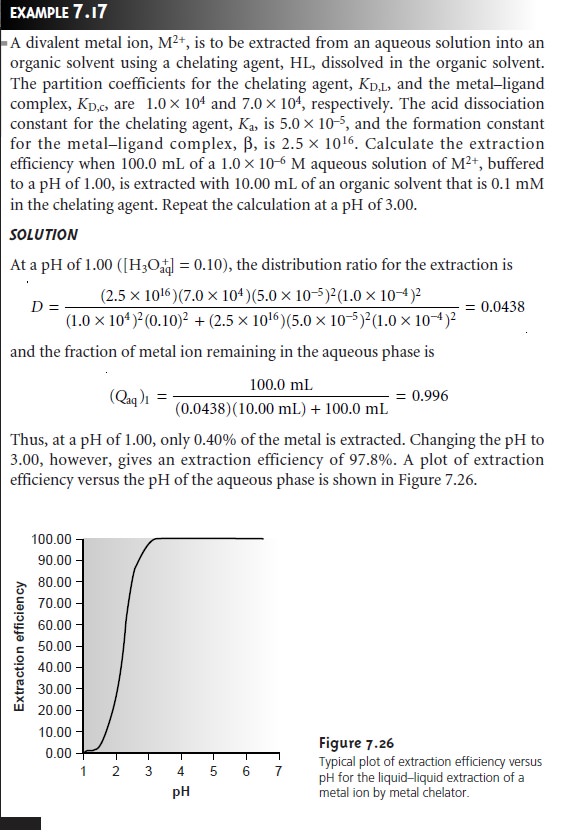

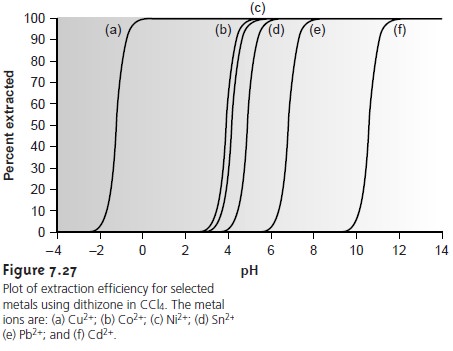

One

of the advantages of using a chelating agent is the high degree of selec- tivity that it brings to the extraction

of metal ions. As shown in Example 7.17 and

Figure 7.26, the extraction

efficiency for a divalent cation increases from approximately 0%ŌĆō100% over a range of only 2 pH units. Furthermore, a chelating

agentŌĆÖs metalŌĆōligand formation constant varies substantially between metal ions. As a result, significant differences arise in the pH range over which different metal ions experience an increase

in extraction efficiency

from 0% to 100%

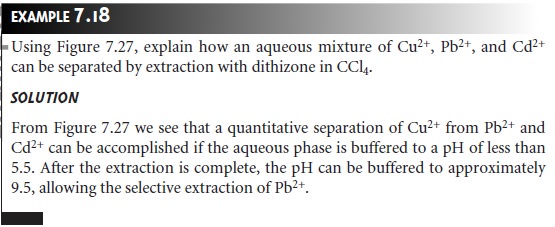

(Figure 7.27).

LiquidŌĆōliquid extractions using ammonium

pyrrolidine dithiocarbamate (APDC) as a metal chelating agent are commonly encountered in the

analysis of metal ions in aqueous

samples. The sample

and APDC are mixed together, and the resulting metalŌĆōligand complexes are extracted

into methyl isobutyl

ketone before analysis.

Related Topics