Chapter: 11th 12th std standard Textiles And Dress Designing Cloth stitch Higher secondary school College practical steps methods Notes

Identification of Right and Wrong Side of fabric

Identification of Right and Wrong Side of fabric

Many fabric look alike on both sides. This results in confusion for a dress maker. Some times few parts may also be cut on the wrong side and attached to the garment Eg. Pocket which is mostly cut from bits lift out after cutting the major parts of the garment. This might go unnoticed but a good dress designer will find this, in a few minutes. Hence it is necessary to understand the right and wrong side of the fabric.

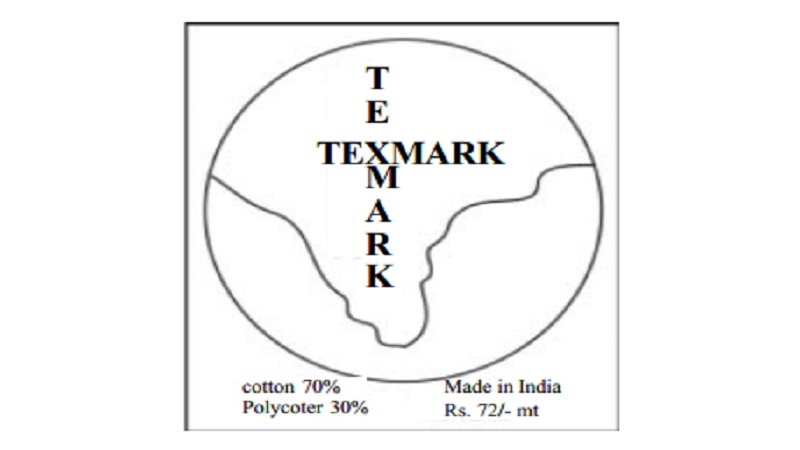

All the fabrics, irrespect of fiber content, variety and end use have label information. The fabric label is a print on the right side of the fabric. This includes information like type of material, cost, name of the company, brand name, symbol, government certified mark (Tex mark) and fiber content. Hence it is easy for any one to identify the right side by seeing this mark. Even on running materials, the cost and fiber content or name of the fabric is printed after every meter.

Label information (Figure)

In case the label information is not found then careful inspection is needed to check the right and wrong side. The fold of the fabric weave, print, texture and finish can act as an guide line to identify the right and wrong side.

Tips to identify right and wrong side

Generally all fabrics are smoother, with less fuzzier surface on the right side.

Woollen and rayon fabrics are always folded on the wrong side out.

Cotton fabrics are always folded on right side out

All woven fabrics have floats or yarns which are not used for the design interlacement on the wrong side.

Printed fabric will look duller on the wrong side, since the printing paste is applied to the right side only. Prints are often blurred on the wrong side.

The selvage is duller on the wrong side for most of the printed fabrics.

Napped fabrics will have the loose yarns on the right side.

Twill fabric will run down toward, on the right side.

Related Topics