Chapter: 11th 12th std standard Textiles And Dress Designing Cloth stitch Higher secondary school College practical steps methods Notes

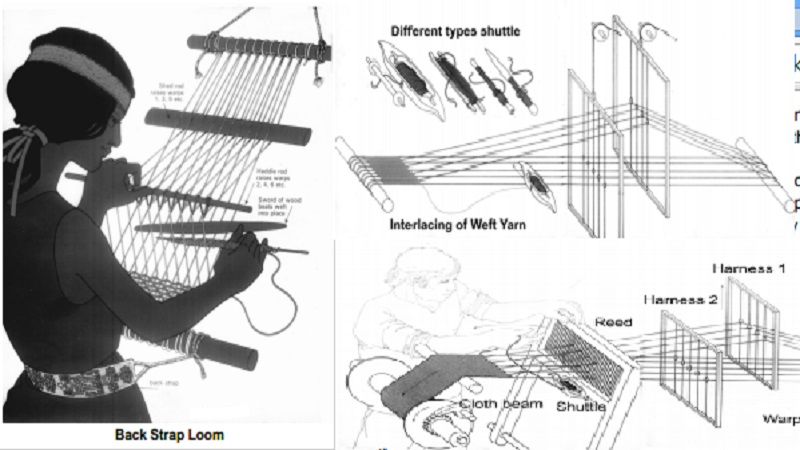

Basic Loom Operations

Basic Loom Operations:

a. Shedding:

It is raising and lowering of warp yarns by the harnessess to make an opening for the weft yarns to pass through.

b. Picking:

It is the actual process of placing the weft yarns in the shed. This is done using a device known as 'shuttle'. It has a metal strip in which bobbin or pin is inserted.

c. Beating:

Sometimes called beating in or beating up, consists of evenly packing the filling yarns into position in the fabric. It gives a compact construction to the fabric.

d. Taking up and letting off:

It involves taking up the newly manufactured fabric onto the cloth beam and letting off or releasing yarn from the warp beam. The operation maintains uniform distance and tension from warp beam to harness to completed cloth.

Weaving is a major method of fabric construction. The technique probably became known before spinning. Spinning developed when people discovered that the raw material could be improved before they were woven. In the course of time, rude looms were made, which were simple and hand-operated, fabrics produced on such looms are also known as hand loom fabrics where every thing is done by hands. The modern power loom used in the textile industry today essentially performs the same operation as the simple hand operated loom. The fabric produced on power looms is made comparitively faster and has few defects in comparison to hand looms.

Based on the picking operations looms are divided into various categories. The two major ones are based upon the method of filling insertion. Looms that uses shuttle are called conventional shuttle or fly shuttle looms. Shuttle looms have very compact selvedge. It is the oldest and versatile method of weaving so most different kinds of fabrics can be obtained. Very large wooden shuttle is used and every time it passes through warp yarns it causes abrasion and the productivity may go down because of the low strength of yarns. The broken yarns show fabric defects. Shuttle looms are very noisy and PPM (Picks Per Minute-How many wefts laid in one minute) is 110 to 225.

On the other hand looms that uses other devices to bring the filling yarn through the shed are called shuttleless looms. The source of the yarn for shuttleless looms are cones placed at the sides of the loom. Shuttle-less looms gives very high productivity at the same time they are less noisy when compared to shuttle-looms. They also have high productivity and fewer fabric faults.

There are different types of looms other than conventional looms such as:

1. Single Projectile on Missile Loom

2. Multiple Projectile System

3. Rapier Loom

4. Jet Looms

Related Topics