Home | Yarn Production : Types, Characteristics of Yarn, Properties

Chapter: 11th 12th std standard Textiles And Dress Designing Cloth stitch Higher secondary school College practical steps methods Notes

Yarn Production : Types, Characteristics of Yarn, Properties

To convert textile fibers into fabrics some type of fiber arrangement is required. Probably the most common method is to convert fibers into yarns, which are then constructed into fabrics.

YARN PRODUCTION

INTRODUCTION:

To convert textile fibers into fabrics some type of fiber arrangement is required. Probably the most common method is to convert fibers into yarns, which are then constructed into fabrics. Yarns are essential for knitted, woven or knotted structures and for many braided ones.

'Yarn' is defined by the American Society for Testing and Materials (ASTM) as 'A generic term for a continuous strand of textile fiber, filament, or material suitable for knitting, weaving to form a textile fabric. Yarn occurs in the following forms.

Yarn forms:

A number of fibers twisted together.

A number of filaments laid together without twist.

A number of filaments laid together with more or less twist.

A single mono filament. e.g. Silk

TYPES OF YARNS:

Yarns can be made either from short staple length fibers or from filament fibers. There are two types of yarns, i.e., spun yarns and filamentous yarns.

Types of Yarns :

1.Spun Yarns

2.Filament Yarns

If filaments are used to make yarns they may be either multifilament or monofilament .

Filamentous Yarns

1.Monofilament

2.Multifilament -> Twisted,Flat

Mono filaments are filament yarns composed of one single filament.

Multi filaments are composed of many filaments.

Characteristics of Spun Yarns and Filament Yarns

Spun Yarn

1. Yarns made from short length fibers and the fabrics are like cotton and wool.

2. Short fibers twisted into continuous strand, has protruding ends

1. Dull, fuzzy look

2. Lint

3. Subject to pilling

4. Soil readily

5. Warm (not slippery)

6. Loft and bulk depend on size and twist

7. Do not snag readily

8. Stretch depends on amount of twist.

3. Are absorbent

4. Size often expressed in yarn number

5. Various amount of twist used

6. Most complex manufacturing process

Filament Yarn

1. Yarns made from long length filament fibers and fabrics are like silk.

2. Long continuous, smooth, closely

1. Smooth, lustrous2. Don not lint3. Do not pill readily4. Shed soil5. Cool, slick6. Little loft or bulk7. Snagging depends on fabric construction8. Stretch depends on amount of twist

4. Absorbency depends on fiber content

5. Size in denier

6. Usually very low or very high twist

7. Least complicated manufacturing process

a. Balanced Yarns:

Smooth fabrics are made from balanced yarns.

b. Unbalanced Yarns:

Crepe and textured surface may be created from unbalanced yarns.

DIRECTION OF TWIST:

In addition to the amount of twist in a yarn, the direction of the twist is also designated. There are two types of yarn twist S and Z.

Yarn Numbering System:

Yarn numbering systems are therefore used to express a relationship between a unit length and weight of yarns. There are two main numbering system in use.

Numbering system

1.Direct -> 1.Denier (900 m1 gms=1 Denier) 2.Tex (1tex=1gm/km 840)

2.Indirect -> 1.Matric No.(840 yds=1lbs=1S) 2.English No.(50/1=50 single yarns)

YARN MANUFACTURING SYSTEM:

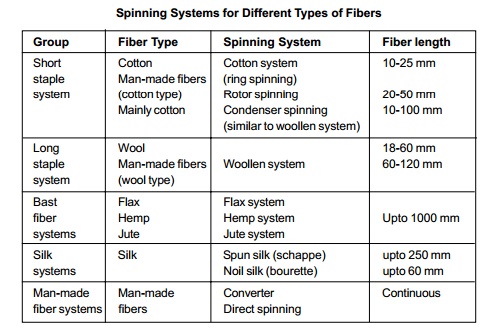

The twisting process by which fibers are formed into a yarn is referred to as spinning. Spinning includes all the processes required to prepare and clean the fibers from the opening of the bale to the twisting of the yarn in its preparation for the textile loom.

1. Opening and Picking:

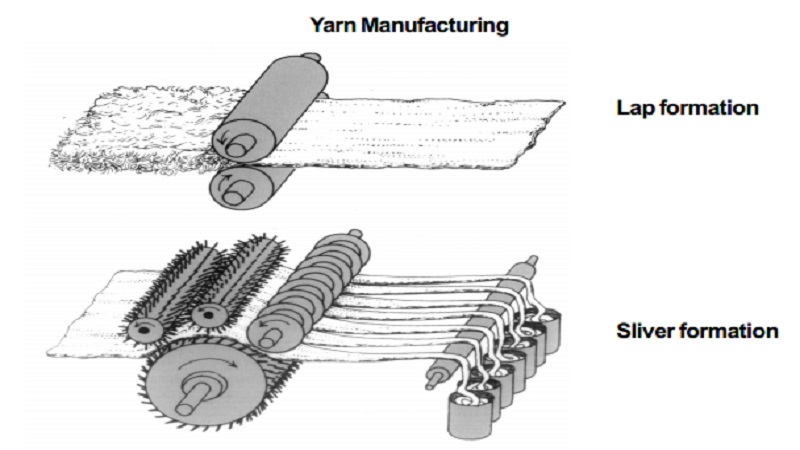

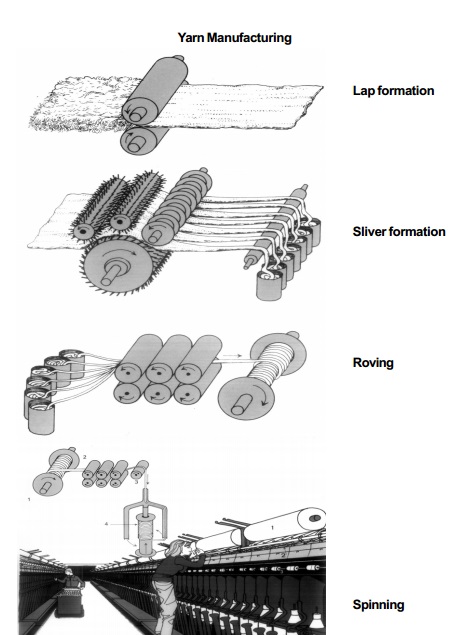

In order to produce a uniform product, the fibers from numerous bales be blended, or thoroughly mixed together, and from this composite, the final yarns will be produced . The masses of fibres from these numerous bales will be fed into a machine called a blending feeder. As these masses of fiber are loosened and thoroughly mixed, some remaining heavy impurities such as dirt, remnants of seeds, leaves or stems, are removed by a line of machine known respectively as pickers, breakers, intermediates and finishers each in succession being a somewhat more refined cleaner of the raw fibres. From these machines, the fabric emerges as a lap, a loose, formless roll.

2. Carding:

The lap is unrolled and drawn onto a revolving cylinder covered with fine hooks or wide bristles. These wide bristles pull the fibers in one direction, separate those which are individually tangled together and form them into a thin film. This process is known as carding. The thin film is drawn into a funnel shaped opening which molds it into a round rope like strand approximately an inch in diameter; this is called the sliver.

3. Combing:

The comber is a refining device by which the paralleling and straightening of the individual fibers is carried to a more exact degree. The longer fibers are again formed into a sliver, known as the comb sliver.

4. Drawing:

In the drawing operation, further blending is accomplished by working together several slivers and drawing or pulling them out in the drawing frame without twisting but reducing the several slivers to a single one about the same diameter as each of the components.

5. Roving:

The combined or condensed combed sliver is taken to the slubber of a series of machines called roving frames.

6. Spinning:

Spinning is a continuation of the roving and on the spinning frame many spools containing the roving pass through the ring spinning mechanism which further draws and twists to a yarn of the required size and twist and winds it on bobbins preparatory to the weaving operation.

TYPES OF YARNS:

1. Textured Yarns:

'Textured' is a general term for any continuous filament yarn whose smooth straight fibers have been displaced from their closely packed, parallel position by the introduction of some form of crimp, curl, loop or coil.

Textured yarns can be made from either filament fibers or staple fibers cut from filaments that have been given a textured configuration of some type. The majority of textured yarns are made from filament fibers. Texturizing occurs following the spinning of the fiber material through the spinneret. It may be done immediately following fiber formation and be a part of a continuous operation or it may be done some time after the filaments have been made. There are three types of textured yarns. 1. Bulk textured yarns 2. Stretch textured yarns 3. 'Set-modified stretch textured yarns.

2. Novelty Yarns:

Novelty yarns are made primarily for their appearance. They differ from simple yarns that their structure is characterized by irregularities. ASTM defines a fancy yarn as a yarn that differs significantly from the normal appearance of single or plied yarns due to the presence of irregularities deliberately produced during its formation.

In single yarn the irregularities may be due to the inclusion of knots, loops, curls, slubs and the like. In plied yarns the irregularities may be due to a variable delivery of one or more of its components or to twisting together dissimilar single yarns.

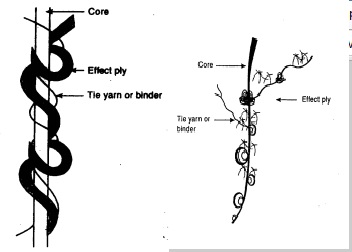

The term fancy, complex and novelty are considered synonymous. As noted from the definition most fancy yarns are either single or plied. There can be endless variety of novelty yarns. A typical novelty yarn has three basic parts: 1.The ground or foundation or core. 2. The fancy or effect 3. The binder.

Facts about novelty yarns:

Novelty yarns are usually ply yarns, but they are not used to add strength to the fabric.

If novelty yarns are used in one direction only, they are usually in the filling direction. They 'go further' and are subject to less strain and are easy to vary for design purpose.

Novelty yarns add interest to plain weave fabrics at lower cost. Novelty yarn effects are permanent.

Novelty yarns that are loose and bulky give crease resistance to a fabric but they make the fabric spongy and hard to sew.

The durability of novelty yarn fabrics is dependent on the size of the novelty effect, how well the novelty effect is held in the yarn and on the firmness of the weave on the fabric. Generally speaking, the smaller the novelty effect, the more durable the fabric is, since the yarns are less affected by abrasion and do not tend to catch and pull out so readily.

Different types of Novelty Yarns:

Slub yarns 2. Flock yarns 3. Spiral yarns 4. Ratine yarn 5. Boucle yarn 6. Nub/spot/ knot or knob yarns 7. Seed or splash yarn 8. Chenille yarn 9. Metallic yarns

PROPERTIES OF SEWING THREADS:

The performance of textile fabrics and clothing is strongly influenced by the properties of the yarns from which they are made. Sewing threads require certain yarn properties.

Regularity : Smooth fabrics should be sewn only with very regular yarns.In spun yarns, this is achieved by repeated doubling and drafting, and by combing out the short fibers.

Strength : Yarn strength depends on the quality of the fibres, the yarn regularity and the twist. Folding increases the strength.

Hardness/Twist : The twist density affects the hardness of a yarn and hence the handle and the appearance of textiles.

Extensibility/ : Extensibility and elasticity are very important during

Elasticity : yarn processing and utilisation. They are determined mainly by the fibre type and the spinning system.

Study Material, Lecturing Notes, Assignment, Reference, Wiki description explanation, brief detail

11th 12th std standard Textiles And Dress Designing Cloth stitch Higher secondary school College practical steps methods Notes : Yarn Production : Types, Characteristics of Yarn, Properties |

Related Topics

11th 12th std standard Textiles And Dress Designing Cloth stitch Higher secondary school College practical steps methods Notes