Chapter: 11th 12th std standard Textiles And Dress Designing Cloth stitch Higher secondary school College practical steps methods Notes

Nylon - Manufacturing Process and Properties

NYLON:

Nylon was the first synthetic fiber. In 1928 the Dupont company decided to establish a fundamental research program. If anything was discovered it would be good for the company - a means of diversification. It was noticed that when a glass rod was taken out of one of the polyester stills the solution adhering to it stretched out into a solid filament. The filament could be stretched ever further and it did not go back to its original length. This stimulated the group to concentrate on textile fibers. The term nylon was chosen for the fiber and it was called the miracle fiber for several years. The first nylon was referred to as type 6,6. The numbers derive from the fact that each of the two chemicals used in making this type of nylon has six carbon atoms. Nylon type 6, 10 was developed at the same time and it is composed of one chemical with six carbon atoms per molecule and ten carbon atoms per molecule for the second chemical. Nylon 6, 6 was considered desirable for apparel and selected home furnishings; nylon 6, 10 was used in making brushes, and similar items. In many countries nylon is identified by term 'Polyamide'.

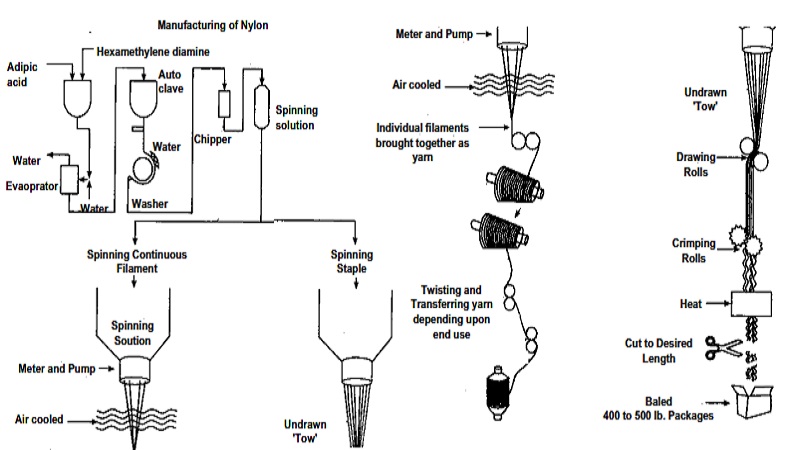

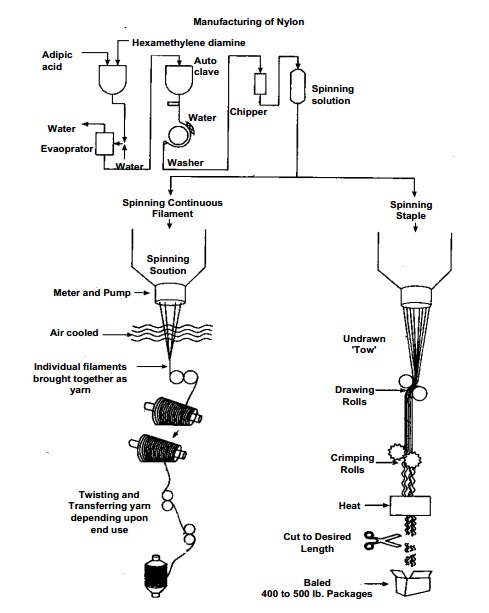

Manufacturing:

Nylon 6, 6 is a linear condensation polymer made from hexamethylene diamine and adipic acid. Specific amounts of the two chemicals are combined in solution to form nylon salt. This salt is purified, polymerized, extruded in ribbon form, and chipped into small flakes or pellets. These flakes or pellets are melted and extruded through a spinneret into cool air and the nylon filaments are formed.

The polymer chips are melted by heat in an autoclave and pumped to the spinneret. The hot syrupy solution is pumped through the spinneret. It emerges in strands which can be stretched like warm taffy. The size of the fiber is determined by the size of the holes and the speed with which the fiber is withdrawn from the spinneret. The fibers are cooled by air blown across them. By the drawing process either filament or staple fibers are prepared.

Properties of Nylon:

Shape : Shape is controlled by the manufacturer, filaments are uniform and long.

Luster : Bright to Dull

Elastic Recovery : 100%

Elongation : Good

Resiliency : Good

Density : 1.1 g / ccm

Moisture absorption : 8%

Dimensional stability : Excellent

Acids : resistance is poor

Alkalies : Good resistance

Sun light : Generally affects

Insects : Normally damages

To flame : Self extinguishing

Related Topics