Chapter: Aquaculture Principles and Practices: Nutrition and Feeds

Feeding techniques - Aquaculture: Artificial feeds

Feeding techniques

While some species start feeding on prepared feeds from the larval stage soon after yolk absorption, others can be started on it only from the juvenile or fry stage. In order to ensure cost-effective use of feeds, feeding levels have to be decided in advance. Feed efficiency is usually expressed in one of two ways:

feed conversion ratio = feed intake / weight gain

or

conversion efficiency = ( weight gain / feed intake) x 100

These are often reported as ratios of dry weight of feed to wet weight of the animal, and this explains the anomalous values sometimes quoted in the literature, such as a ratio of 1 : 1 or even less.

Feeding levels depend to a large extent on the system of culture, nature of the feed, temperature conditions and feeding behaviour of the species. Generally speaking, feed requirements, in volume or weight, increase with the size of the animal, but the requirement per unit of weight decreases with the increase in size.

For example, the feed requirements of a 1 kg fish will be less than of 10 fish of 100 g each (weighing in total 1 kg).

Ideally, feeding levels should be based on the dietary energy requirements or the metaboliz-able energy value of the feeds. In the absence of such information, the daily feed requirements are often calculated as percentages of the live weight of the animals cultured. This is valid when using complete feeds, but in cases where the prepared feed is used as a supplement to natural food, calculations of artificial feeding levels become much less precise. The aquaculturist has to fall back on trial-and-error methods and practical experience.

Feeding rates

Rapidly growing fry of about 0.25 g generally require as much as 10 per cent of their weight daily, but as they grow and reach about 4 g in size the ration can be reduced to about 5 per cent of body weight per day. Many farmers overfeed at the fry stage for better growth and survival, but then special precautions have to be taken to avoid fouling of the water. The frequency of feeding decreases from about eight times a day for fry weighing less than 1.5 g to four times a day for advanced fry.

Culturists often maintain feeding charts to guide in daily feeding in grow-out farms. It is generally held that feeding in excess of twice a day has no beneficial effect on growth rate or food conversion efficiency; in most cases once daily would be adequate. The total amount of feed to be provided is generally estimated by multiplying the weight representing the desired growth by the conversion rate of the feed used. However, the calculation of the daily feeding rates has to be based on a percentage of the estimated biomass to be fed, making appropriate adjustments for daily increments in the biomass. The animals can also be fed ad libitum until they become satiated. When this is not practised, adjustments of feeding rate can be made on the basis of biomass estimated from measurements of small samples at regular intervals. If the feed conversion ratio for a species is known and can be assumed to be constant, the daily changes needed in the feeding rate can be calculated on an assumed specific growth rate. Studies on the effects of feeding frequency on the growth of fish seem to indicate that there is an optimum frequency, above which additional feedings produce no advantage. This frequency seems to be related also to the size of the stomach, since specieswith smaller stomachs require more frequent feeding for maximum growth.

The ration has to be adjusted according to the water temperature, which affects the meta-bolic rate of the animal. According to Stickney (1979), channel catfish should be fed no more than 1 per cent (percentage of body weight to feed) daily, when the temperature is above 32°C. Between 21 and 32°C, they are generally fed 3 per cent of the body weight per day and this amount is reduced to 2 per cent at 16–21°C and 1 per cent at 7–16°C. Many culturists do not feed during winter, and below 7°C the fish may not consume much feed, except on warmer days. In tropical countries, where the fluctuations in water temperature are not so great, the adjustments in the amount of feed could also be less.

Feed dispensing

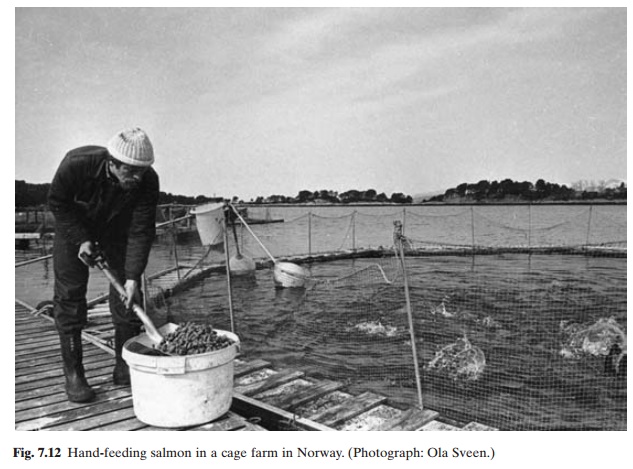

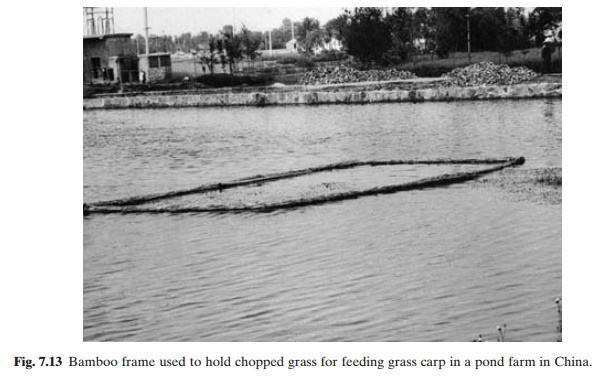

The most common method of feed dispensing is hand-feeding (fig. 7.12). Though it is labour intensive, it has the advantage that the farmer can observe his stock regularly, especially if feeding takes place at the surface. In pond farms, feeding is usually done in a specific place, which can be marked out by poles to enable regular checking for left-over feed (fig. 7.13). If there is an accumulation of left-over feed, provision of fresh feed is stopped until the old feed is used up. Some farmers prefer to dispense feed at the harvesting sump, as the feeding fish will stir up the deposited silt and keep the sump clean. The animals generally learn to congregate near the feeding spot at the usual feeding time. In cage culture of salmon and trout, wet feed is almost always fed by hand.

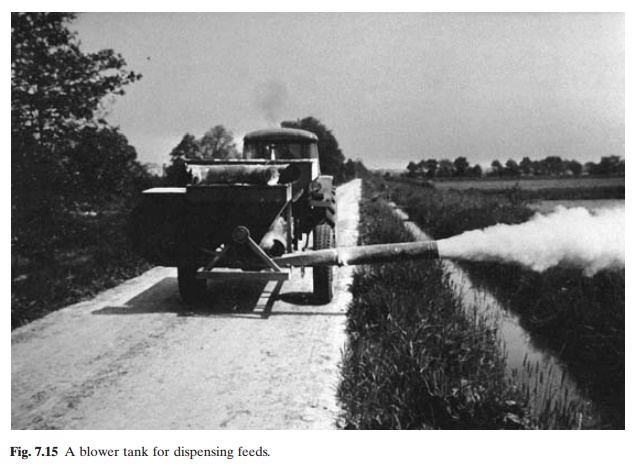

Several mechanical aids for hand feeding are available, such as hand-operated blowers and ‘disc throwers’. A boat can be used for hand feeding in large ponds and other enclosures. Blower tanks facilitate the dispensation of prepared feeds, as well as feedstuffs such as cereals. The impeller in the tank blows the feed through a slanted pipe to a distance of about 10 m into the pond or enclosure. When mounted on a truck or towed by a tractor, the blower can be propelled by the motor of the vehicle. The actual quantity of feed applied can be measured with the help of an auger, which transfers the feed to the blower. With each turn of the

auger a certain amount of feed is transferred, and by counting the rotations of the auger on a meter the amount can be calculated. Wet-feed dispensers are sometimes used, particularly in sea cage farming of salmon and trout. Wet feed, prepared with a blender, is put into a hopper and the rotating arm at the bottom expresses the feed through a slit. An alternative arrangement consists of an electrically driven screw at the bottom of the hopper, which expels the food through a nozzle in a continuous ‘worm’. Spokes projecting from a revolving wheel cut the ‘worm’ into wet pellets of required size as it emerges from the nozzle. The pellets drop into a long plastic drainpipe, which extends out into the sea enclosure.

Certain types of feeds, such as dough for eels, are presented on submerged platforms from which the animal can feed with minimum feed loss. In some countries, stationary feeders consisting of a feed hopper fitted over a submergedshallow circular plate are used. Feed falls, by the pressure of the feed and gravity, into the circular plate from where the animal feeds. As the feed from the container is used up, more feed from the hopper falls to fill it.

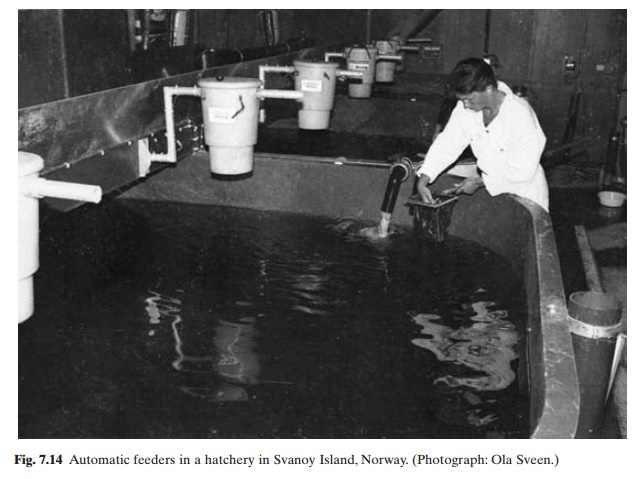

Different types of automatic feeders are used for prepared feeds in larval tanks and grow-out areas (fig. 7.14). Electrically activated timing devices make it possible to dispense set amounts of feed at given intervals. This enables a certain frequency and duration of feeding, which can be adjusted according to the varying demands related to life stages, seasons, water temperature, oxygen content, etc. There are different patterns of dispersal. The feed may drop directly into the water from the storage bin or be dispersed widely by falling on to a rotating disc, which can fling the pellets out over the water. In another model, electrical impulses are received by a vibrator situated just inside the opening at the bottom of a conical feed hopper.

Underneath the hopper is a small plastic disc which is an integral part of the vibrator. Pellets fall by gravity on to the disc, which vibrates each time impulses are received. They are then thrown off the disc into the water and the vibrating action also ensures that the pellets in the hopper are kept freely running. Other models distribute feeds from a shore-based storage bin by means of a screw conveyer or auger rotating within a tube which extends over the water. The pellets fall into the water through perforations along the bottom of the tube as they are conveyed out by the screw. The animals feed from a wide area, along the conveyor and at the end of the conveyor run. Other large feed distribution systems use pneumatic tubes through which pellets are blown.

Mechanisms using compressed air to distribute pellets over the water have been used successfully in raceway culture. Mobile mechanical feeding systems such as blowers are used to dispense feed over large areas by means of a nozzle at the end of a boom reaching out over the water as the feeder moves along the water’s edge (fig. 7.15). Dispensing feed in a stream of water ejected through a nozzle has also been found to be effective. Nevertheless, many farmers prefer to distribute only 70–80 per cent of the feed by an automatic device and the rest is fed by hand in order to observe the feeding behaviour of the stock and ensure that the feed is made available to all the animals as required.

An increasing number of aquafarms in industrially advanced countries are using computer-controlled automatic feeders, where the quantity of feed and frequency of feeding are regulated through appropriate programs that take into account several variables such as stock density, growth rate, conversion rates, temperature conditions, mortality, harvest time, etc.

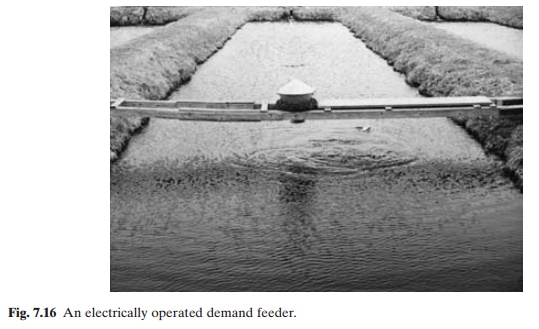

Other types of mechanical feeders in use are demand feeders, which are activated by the animals themselves by means of a rod or plate hanging from the feeder into the water (fig. 7.16). Movement of the rod or plate (referred to also as bait) releases a small quantity of pellets from a hopper. They can be less expensive than automatic feeders, even though the number of such feeders needed in a farm may be relatively high. They can be easily fabricated from inexpensive materials on the farm itself. There is no need for electrical supply, so such feeders can be installed in rural farms that have no electricity. Fish very soon learn to activate

the feeder and generally do so only when they want to feed, although in high-density culture conditions inadvertent activation can occur. Generally, demand feeders avoid wastage of feed and the creation of anoxia due to bacterial decomposition of unused feed.

Demand feeders permit ad libitum feeding, but there is a difference of opinion as to whether this helps in improving feed conversion ratios. There appears to be no conclusive proof one way or the other, but under experimental conditions it has been observed that uniform distribution of the feed is impeded by competition, the more aggressive animals being able to activate the feeder more frequently and obtain greater amounts of feed. This leads to uneven growth and size composition of the stock. It is expected that the weaker ones would get their chance to feed after the stronger ones had fed to satiation, but in practice this does not always appear to happen.

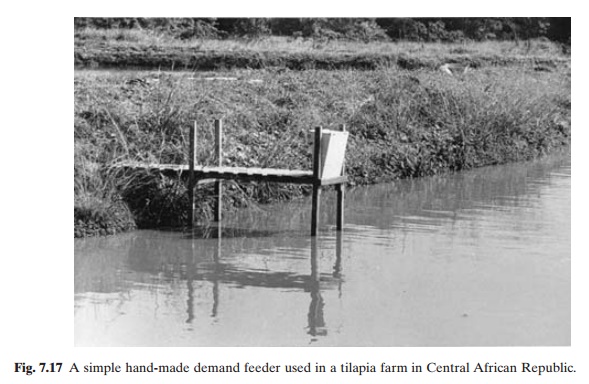

Different models of demand feeders are manufactured commercially but, as indicated earlier, simple ones can be made on a farm (fig. 7.17). A demand feeder consists essentially of a feed container with a conical bottom with an opening of about 5 cm diameter in the centre, through which hangs a rod or metallic chain of 12–14 mm thickness. A ball or inverted cone is mounted on the rod or chain in such a way as to more or less block the opening of the container. A small plate can be welded at the end of the rod or chain to facilitate activation by the fish. When the rod or the chain is moved aside by the fish, the feed falls into the water through the gap produced. If the capacity of the feeder is small, frequent refilling of pellets will be needed. This can be done manually or from feed distribution trucks at regular intervals.

Related Topics