Chapter: Aquaculture Principles and Practices: Nutrition and Feeds

Feed formulation and feed formulae - Artificial feeds

Feed formulation and feed

formulae

The primary objective of feed formulation is to provide the species

under culture with an acceptable diet that meets its nutritional requirements

at different stages of its life, so as to yield optimum production at minimum

cost. As has already been pointed out, our present knowledge of the nutritional

needs of aquatic animals is restricted to only a few species, and feed

formulation for other species has to be approximated on this basis. Although it

is most likely that all aquaculture species can be weaned to consume processed

compound feeds, there is still a lot to be learnt about the physical and

chemical properties of diets preferred by several species. Flavour, colour,

odour, texture and water stability are important characteristics related

to acceptance and consumption. Better knowledge of preferences and feeding

behaviour would greatly improve the choice of appropriate ingredients and feed

preparation processes, as well as the methods of feed dispensing.

For formulating the basic composition of a feed, the main information

needed are the levels of crude protein, energy, specific amino acids, crude

fibre and ash required. The energy level may be in terms of metabolizable

energy

(ME) or digestible energy (DE). Most complete practical diets have to be

supplemented with a vitamin premix, at levels in excess of the dietary

requirement. All levels, with the exception of energy, are determined on the

basis of chemical tests on samples of a feedstuff. Even though they correlate

well with biological methods of feed evaluation, such as growth studies, tissue

levels, etc., they are subject to errors due to variability in composition. For

example, the proximate composition of fish meal made from spawning fish is

different from that made from immature fish. Usually, the lipid levels increase

before spawning and decrease afterwards, changing the percentage compositions

of protein, ash and carbohydrates. Many plant feedstuffs also show

compositional variations according to season, locality and environment.

However, formulations have often to be based on average values.

Another problem to be considered is seasonality in the availability of

ingredients. It may not always be possible to store large quantities of

ingredients, and so it becomes necessary to vary ingredient composition

according to availability. In many developing countries where feedstuffs are

scarce, one cannot expect sufficient priority to be given to their use in

aquaculture. Even when a particular feedstuff is available for purchase,

increased prices may make it necessary to use substitutes in order to obtain a

least-cost ration. It therefore follows that there are no fixed formulae for

feeds and that they have to vary according to availability of ingredients,

composition and costs. Least-cost feeds have to be formulated, but in doing so

careful consideration has to be given to the quality of the nutrient content in

substitute ingredients. Changes of ingredients or their proportions may also

affect the physical characteristics and palatability of the diets. So feed

costs should be estimated not on the basis of the price of ingredients alone,

but also on the proportion of feed costs in the overall production cost per

unit weight of fish.

The type of feed required and the methods of processing will influence

formulation. Extruded or floating-type feeds must contain an appreciable

quantity of starch for satisfactory gelatinization and expansion. Most such

feeds contain 20–25 per cent cereal grain such as corn, wheat or sorghum.

Again, depending on the storage conditions and duration of storage, a certain

amount of loss of vitamins has to be expected. In order to cover such loss, it

will be necessary to add higher levels of vitamins than are nutritionally

required.

The type of culture system also has a determining role in feed

formulation. For example, if the feed is for use in semi-intensive pond

culture, certain vitamin and mineral supplements can be omitted from the

formula, as these nutrients are likely to be available to the animal from the

natural food organisms growing in the ponds. On the other hand, in intensive

culture in cages, raceways and tanks, where natural foods are limited, the diet

should contain all the required nutrients in adequate quantities and

proportions. Similarly, when the feed is meant to be used as supplementary

feed, to augment the major nutritional elements provided by natural food, the

formulations will have to be based on the quantitative assessment of additional

requirements of these elements. The problems of formulating supplementary feeds

were mentioned.

Since protein is the most expensive portion of an animal diet, it is

usually computed first in diet formulation. The first step consists of

balancing the crude protein and energy levels. Then the levels of indispensable

amino acids should be assessed to ensure that the animal’s dietary levels in

this respect are met. Except in the case of unconventional protein supplements,

if the feedstuff has the required dietary levels of arginine, lysine,

methionine and tryptophan it is most likely that the other six indispensable

amino acids are above required levels (Hardy, 1980). In cases where the

formulation is low in amino acids, necessary alterations have to be made by the

addition of ingredients with

high levels of the required amino acids. After this is done, a final

check will be necessary to ensure that the balance of protein and energy levels

is not altered.

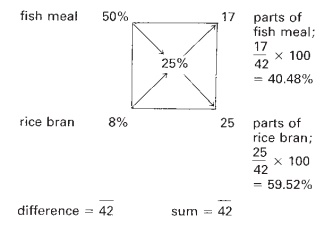

The most commonly used methods for balancing crude protein levels are

the square method and algebraic equations. For example, to balance a

supplementary feed to contain 25 per cent protein, using only two ingredients –

fish meal (50 per cent protein) and rice bran (8 per cent protein) – a square

is constructed as shown above. The desired protein level of the feed (25 per

cent) is inserted in its centre. The two feedstuffs, along with their protein

content, are placed on each corner at the left-hand side of the square and the

levels of protein of each feedstuff are subtracted from the desired protein

level of the feed. The differences are placed on the corners of the square

diagonally opposite the feedstuff, ignoring plus or minus signs (see diagram).

The difference between the percentages of protein in the rice bran and the

protein required in the feed under formulation show the proportion of fish meal

needed. The difference between the protein percentage of fish meal and of the

feed being formulated show the proportion of rice bran required. These

proportions can be expressed on a percentage basis, as 40.48 per cent fish meal

and 59.52 per cent rice bran, or as a ratio of 17 parts: 25 parts.

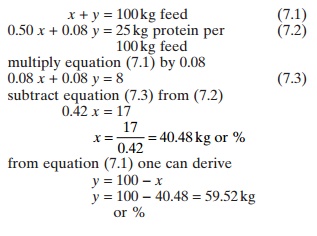

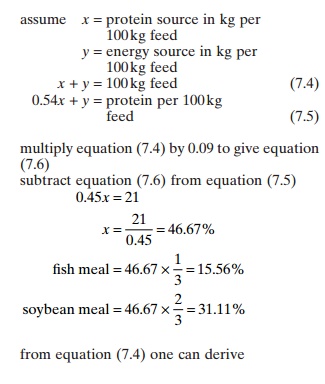

Algebraic equations can be used to arrive at the same percentages as

follows:

assume

x =fish meal in kg per 100 kg feed

y =rice

bran in kg per 100 kg feed

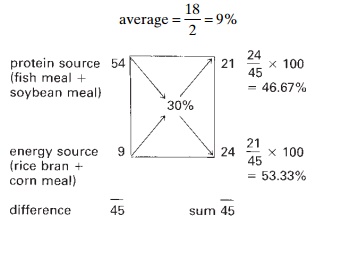

In actual practice, more than two ingredients are generally used in feed

formulations. The use of both the square method and algebraic equations is

illustrated in the following example to balance a diet containing 30 per cent

protein using fish meal (60 per cent protein), soybean mean (51 per cent

protein), rice bran (8 per cent protein) and corn meal (10 per cent protein) in

the proportions 2 parts soybean meal: 1 part fish meal and 1 part rice bran to

1 part corn meal.

Using the square method as in the above example, the desired protein

level (30 per cent) is placed in the middle of the square. The ingre-dients are

separated into two groups and the protein level of each group calculated

according to the proportion specified:

protein source: fish meal = 1 x 60 = 60%

soybean meal = 2 x 51 = 102%

average = 162/3 = 54%

energy source: rice bran = 1 x 8 = 8% corn meal = 1 x 10 = 10%

average = 18/2 = 9%

The protein and energy sources, along with their calculated protein

contents are placed on each corner at the left-hand side of the square. After

diagonal subtraction, the calculation proceeds as shown below. The final figure

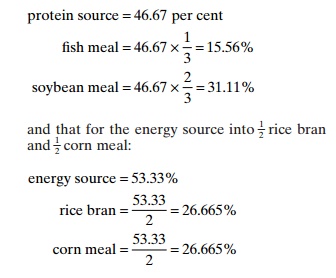

for the protein source is divided into 2/3 soybean meal and 1/3 fish meal:

protein source = 46.67 per cent

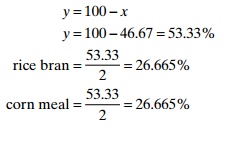

If the algebraic equation method is used, the ingredients are separated

into two groups and the protein level of each group calculated according to the

proportion required:

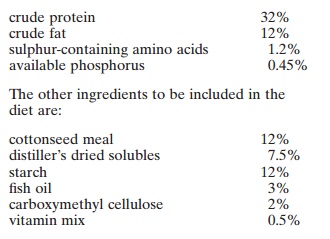

Very often, more complicated formulations than the ones described above

will become necessary. For example, the diet may have to be for-mulated to

contain specified amounts of certain feedstuffs and concentrations of various

nutrients, as in the following example (Lim, 1982).

An allplant diet has to be made using soybean meal and peanut meal in

the ratio 1 : 1 as protein source, with the following nutrient specifications:

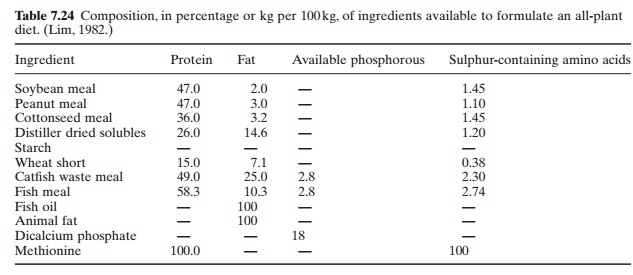

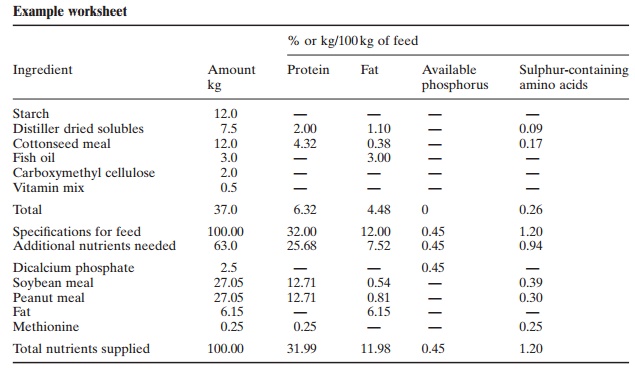

The composition of the available ingredients is listed in Table 7.24.

The formulation proceeds as follows. A work sheet (as shown in the example) is

made up and the required feed ingredients and amounts filled in first.The

nutrients that will be furnished by these ingredients are calculated as a

percentage (or kg per 100kg feed) according to available data on their nutrient

composition. By adding up the items, the total amounts of each nutrient

supplied by the feedstuffs are obtained. By subtracting these amounts from the

level of nutrients required in the formulated feed, the additional amounts of

nutrients needed and the quantities of other ingredients to provide those

nutrients are deter-mined.As soybean meal and peanut meal do not contain any

available phosphorus, dicalcium phosphate should be added. As dicalcium

phosphate contains 18 per cent available phosphorus, the required

quantity per 100 kg is 0.45/ 0.18 = 2.5 kg. This leaves 100 - 39.5 = 60.5 kg

per 100 kg (or per cent) of other ingredients. If this is to be supplied by

soybean meal and peanut meal in equal proportions, the nutrients will be

provided by 2.44 kg protein, 1.51 kg fat and 0.77 kg sulphur-containing amino

acids per 100 kg.Since these do not meet the full requirements for fat and

sulphur-containing amino acids, animal fat and methionine have to be added. The

same results can be obtained by using algebraic equations.

Linear programming in feed formulation is a mathematical procedure to

obtain the optimum solution to specified objectives. It is of special

importance in least-cost ration formulation, as there are many ingredients that

can provide the necessary protein levels in a ration and there may be a need to

change ingredients according to availability, price and quality. While there

may be several possible solutions to achieving a given set of specifications,

there will be one formulation that costs the least. This elaborate calculation

involes the simultaneous solution of a number of linear equations and can best

be

done with a computer. It is widely practised in livestock and poultry

feed manufacture and has been used in the manufacture of fish feeds.

For formulation of least-cost rations, the computer should have the

ration specifications together with the nutrient requirements of the animal.

The critical nutrients such as methion-ine and lysine are specified as minimum,

range, ration or exact amounts. Nutrients, such as trace elements and vitamins,

which are supplied at constant levels need not be indicated. Relevant

specifications of the feedstuffs to be used should be put in, along with the

composition and price of various available feedstuffs to be included in the

formula. Since the accuracy of the formula will depend on the exact nutrient

composition of the feedstuffs to be used, the values should be as accurate as

possible. Prices used should be those at the time and point where the feed is

made, in order to obtain a realistic and effective least-cost ration. By

expressing these various data inputs as constraints or restrictions, a series

of linear equations are formed. Successful solution of the various simultaneous

linear equations leads to an optimal solution. When erroneous ingredient data

are used or when unreasonable restrictions are placed on nutrient requirements

or ingredient usage, the computer may report that a solution is not feasible.

This normally happens only when there are errors in data input. It is therefore

essential to check the information thoroughly and input only precise data.

Related Topics