Chapter: Basic Electrical and electronics : Electrical Mechanics

Construction of DC Machines

DC GENERATOR - INTRODUCTION

An

electrical generator is a device that converts

mechanical energy to electrical energy,

generally using electromagnetic induction. The source of mechanical energy may

be a reciprocating or turbine steam

engine, water falling through a turbine or waterwheel, an internal combustion

engine, a wind turbine, a hand crank, or any other source of mechanical energy.

The

Dynamo was the first electrical generator capable of delivering power for industry.

The dynamo uses electromagnetic principles to convert mechanical rotation into

an alternating electric current. A dynamo machine consists of a stationary

structure which generates a strong magnetic field, and a set of rotating

windings which turn within that field. On small machines the magnetic field may

be provided by a permanent magnet; larger machines have the magnetic field

created by electromagnets. The energy conversion in generator is based on the

principle of the production of dynamically induced e.m.f. whenever a conductor

cuts magneticic flux, dynamically induced e.m.f is produced in it according to

Faraday's Laws of Electromagnetic induction. This e.m.f causes a current to

flow if the conductor circuit is closed.

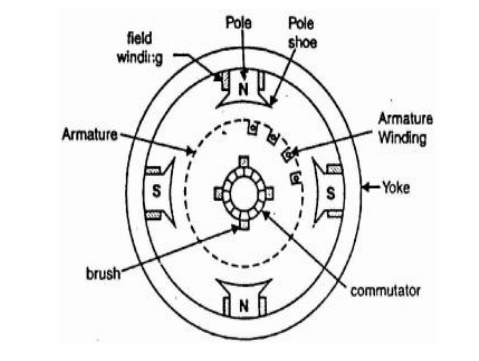

CONSTRUCTION OF D.C. MACHINES

A D.C.

machine consists mainly of two part the stationary part called stator and the

rotating part called rotor.The stator consists of main poles used to produce

magnetic flux ,commutating poles or interpoles in between the main poles to

avoid sparking at the commutator but in the case of small machines sometimes

the interpoles are avoided and finally the frame or yoke which forms the

supporting structure of the machine. The rotor consist of an armature a

cylindrical metallic body or core with slots in it to place armature windings

or bars,a commutator and brush gears The magnetic flux path in a motor or

generator is show below and it is called the magnetic structure of generator or

motor.

The major parts can be identified as,

1. Frame

2. Poles

3. Armature

4. Field

winding

5. Commutator

6. Brush

7. Other

mechanical parts

Frame

Frame is

the stationary part of a machine on which the main poles and commutator poles

are bolted and it forms the supporting structure by connecting the frame to the

bed plate. The ring shaped body portion of the frame which makes the magnetic

path for the magnetic fluxes from the main poles and interpoles is called Yoke.

Why we use cast steel instead of cast iron for the

construction of Yoke?

In early

days Yoke was made up of cast iron but now it is replaced by cast steel.This is

because cast iron is saturated by a flux density of 0.8 Wb/sq.m where as

saturation with cast iron steel is about 1.5 Wb/sq.m.So for the same magnetic

flux density the cross section area needed for cast steel is less than cast

iron hence the weight of the machine too.If we use cast iron there may be

chances of blow holes in it while casting.so now rolled steels are developed

and these have consistent magnetic and mechanical properties.

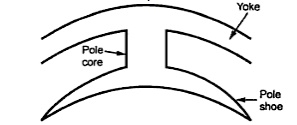

poles:

Solid

poles of fabricated steel with separate/integral pole shoes are fastened to the

frame by means of bolts. Pole shoes are generally laminated. Sometimes pole

body and pole shoe are formed from the same laminations. The pole shoes are

shaped so as to have a slightly increased air gap at the tips. Inter-poles are

small additional poles located in between the main poles.

These can

be solid, or laminated just as the main poles. These are also fastened to the

yoke by bolts. Sometimes the yoke may be slotted to receive these poles. The

inter poles could be of tapered section or of uniform cross section. These are

also called as commutating poles or com poles. The width of the tip of the com

pole can be about a rotor slot pitch.

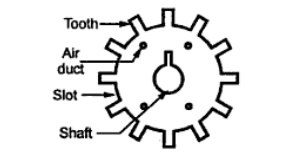

Armature

The

armature is where the moving conductors are located. The armature is

constructed by stacking laminated sheets of silicon steel. Thickness of these

lamination is kept low to reduce eddy current losses. As the laminations carry

alternating flux the choice of suitable material, insulation coating on the

laminations, stacking it etc are to be done more carefully. The core is divided

into packets to facilitate ventilation. The winding cannot be placed on the

surface of the rotor due to the mechanical forces coming on the same. Open

parallel sided equally spaced slots are normally punched in the rotor

laminations.

These

slots house the armature winding. Large sized machines employ a spider on which

the laminations are stacked in segments. End plates are suitably shaped so as

to serve as ’Winding supporters’. Armature construction process must ensure

provision of sufficient axial and radial ducts to facilitate easy removal of

heat from the armature winding.

Field windings:

In the

case of wound field machines (as against permanent magnet excited machines) the

field winding takes the form of a concentric coil wound around the main poles.

These carry the excitation current and produce the main field in the machine.

Thus the poles are created electromagnetically. Two types of windings are

generally employed. In shunt winding large number of turns of small section

copper conductor is used. The resistance of such winding would be an order of

magnitude larger than the armature winding resistance. In the case of series

winding a few turns of heavy cross section conductor is used. The resistance of

such windings is low and is comparable to armature resistance. Some machines

may have both the windings on the poles. The total ampere turns required to

establish the necessary flux under the poles is calculated from the magnetic

circuit calculations. The total mmf required is divided equally between north

and south poles as the poles are produced in pairs. The mmf required to be

shared between shunt and series windings are apportioned as per the design

requirements. As these work on the same magnetic system they are in the form of

concentric coils. Mmf ’per pole’ is normally used in these calculations.

Armature winding As mentioned earlier, if the armature coils are wound on the

surface of the armature, such construction becomes mechanically weak. The

conductors may fly away when the armature starts rotating. Hence the armature

windings are in general pre-formed, taped and lowered into the open slots on

the armature. In the case of small machines, they can be hand wound. The coils

are prevented from flying out due to the centrifugal forces by means of bands

of steel wire on the surface of the rotor in small groves cut into it. In the

case of large machines slot wedges are additionally used to restrain the coils

from flying away. The end portion of the windings are taped at the free end and

bound to the winding carrier ring of the armature at the commutator end. The

armature must be dynamically balanced to reduce the centrifugal forces at the

operating speeds. Compensating winding One may find a bar winding housed in the

slots on the pole shoes. This is mostly found in d.c. machines of very large

rating. Such winding is called compensating winding. In smaller machines, they

may be absent.

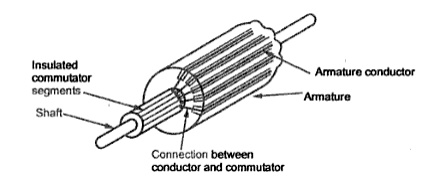

Commutator:

Commutator

is the key element which made the d.c. machine of the present day possible. It

consists of copper segments tightly fastened together with mica/micanite

insulating separators

on an

insulated base. The whole commutator forms a rigid and solid assembly of

insulated copper strips and can rotate at high speeds. Each commutator segment

is provided with a ’riser’ where the ends of the armature coils get connected.

The surface of the commutator is machined and surface is made concentric with

the shaft and the current collecting brushes rest on the same. Under-cutting

the mica insulators that are between these commutator segments has to be done

periodically to avoid fouling of the surface of the commutator by mica when the

commutator gets worn out. Some details of the construction of the commutator

are seen in Fig

Brush and brush holders:

Brushes

rest on the surface of the commutator. Normally electro-graphite is used as

brush material. The actual composition of the brush depends on the peripheral

speed of the commutator and the working voltage. The hardness of the graphite

brush is selected to be lower than that of the commutator. When the brush wears

out the graphite works as a solid lubricant reducing frictional coefficient.

More number of relatively smaller width brushes are preferred in place of large

broad brushes. The brush holders provide slots for the brushes to be placed. The

connection Brush holder with a Brush and Positioning of the brush on the

commutator from the brush is taken out by means of flexible pigtail. The

brushes are kept pressed on the commutator with the help of springs. This is to

ensure proper contact between the brushes and the commutator even under high

speeds of operation. Jumping of brushes must be avoided to ensure arc free

current collection and to keep the brushcontact drop low. Other mechanical

parts End covers, fan and shaft bearings form other important mechanical parts.

End covers are completely solid or have opening for ventilation. They support

the bearings which are on the shaft. Proper machining is to be ensured for easy

assembly. Fans can be external or internal. In most machines the fan is on the

non-commutator end sucking the air from the commutator end and throwing the

same out. Adequate quantity of hot air removal has to be ensured. Bearings

Small machines employ ball bearings at both ends. For larger machines roller

bearings are used especially at the driving end. The bearings are mounted

press-fit on the shaft. They are housed inside the end shield in such a manner

that it is not necessary to remove the bearings from the shaft for dismantling.

End Shields or Bearings

If the

armature diameter does not exceed 35 to 45 cm then in addition to poles end

shields or frame head with bearing are attached to the frame.If the armature

diameter is greater than 1m pedestral

type bearings are mounted on the machine bed plate outside the frame.These

bearings could be ball or roller

type but generally plain pedestral bearings are employed.If the diameter of the

armature is large a brush holder yoke

is generally fixed to the frame.

Related Topics