Chapter: 11th 12th std standard Class Organic Inorganic Physical Chemistry Higher secondary school College Notes

Chromium: Occurrence, principles of extraction, Properties, Uses and alloys

Occurrence and principles of extraction of chromium Chromium

Atomic mass : 51.99 Valency

: 0,1,2,3,4,5,6

Atomic number : 24 Symbol : Cr

Position in the periodic table : Period Number -4, Group

Number -6.

L.N. Vanquelin, a french chemist discovered a new element

in 1797, while examining a mineral

found in Siberia. It was named chromium because it forms coloured compounds [Greek word - chroma - colour]

Occurrence

Metallic chromium does not occur in the native state. In

India chromite ore occurs in Bihar, Mysore, Chennai and Bombay.

Ores

The important ore of chromium is Chromite or chrome ore, FeO Cr2O3

The chief ore of chromium is chromite ore.

Extraction of chromium metal from chromite ore

The extraction of chromium metal from chromite ore

consists of the following steps.

1. Concentration

The crushed ore is concentrated by gravity separation

method.

2. Conversion of the concentrated chromite ore into

Na2CrO4

The concentrated ore is mixed with excess of Na2CO3 and a small amount of lime and roasted in a reverberatory furnace at

900-1000 o C in the presence of free

supply of air. During this process, chromite ore is converted into soluble sodium chromate.

4(FeO. Cr2O3) + 8Na2CO3 + 7O2 (from

air)

Chromite ore ¯ 900-1000 o C

8Na2CrO4 +2Fe2O3 + 8CO2

Soluble Insoluble

Conversion of Na2CrO4 into Na2Cr2O7

The solution containing Na2CrO4 is treated with a calculated quantity of

H2SO4,

Na2CrO4 is converted into Na2Cr2O7.

2Na2CrO4 + H2SO4 ® Na2Cr2O7 + Na2SO4 + H2O

Conversion of Na2Cr2O7 into Cr2O3

Na2Cr2O7 is heated with carbon to get sodium chromite,

Na2Cr2O4 which

on treatment with H2O, gives Cr2O3 precipitate.

Na2Cr2O7 + 3C ® Na2Cr2O4 + 3CO

Na2Cr2O4 + H2O ® Cr2O3¯ + 2 NaOH

Reduction of Cr2O3 to

chromium metal

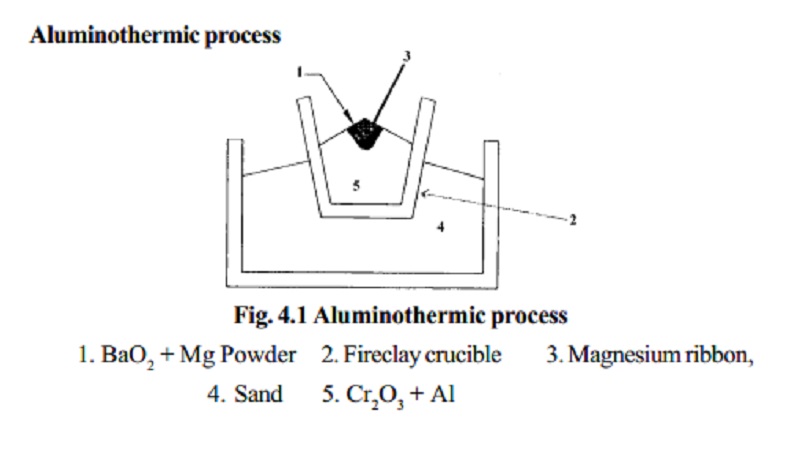

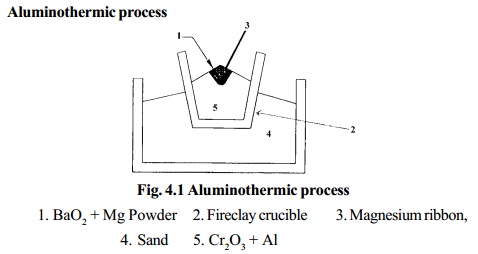

Aluminothermic process

1. BaO2 + Mg

Powder

2. Fireclay crucible

3. Magnesium ribbon,

4. Sand

5. Cr2O3 + Al

Chromic oxide is mixed with powdered Aluminium in the

ratio 3:1 and is

placed in a large fire clay crucible. A mixture of barium

peroxide and Mg powder is placed over

this. The crucible is surrounded by sand which prevents loss of heat by

radiation. The mixture is ignited by a piece of Mg ribbon. During this

process a large amount of heat is liberated, in which Cr2O3 is reduced to chromium.

The molten chromium is collected in the crucible and

aluminium oxide is removed

as slag.

Cr2O3 + 2Al ®2Cr + Al2O3 + 468.6

kJ

Properties of Cr

Physical Properties

1. The metal is silvery white and crystalline. 2. It is very hard and brittle 3. It melts at 2113K.

Chemical Properties

1. Action of air : It is unaffected by air at ordinary temperatures.

When heated to very high temperature at about 2000 o C it

is oxidised to

chromic oxide.

4Cr

+ 3O2 ® 2Cr2O3

2. Action of Water : There is no action at

ordinary temperatures. However it

decomposes steam at red heat to give chromic oxide and

hydrogen.

2Cr

+ 3H2O ® Cr2O3 + 3H2

3. Action of Acids : It dissolves in dilute

hydrochloric acid and sulphuric acid to

liberate hydrogen and forms chromous salts.

Cr + 2HCl ® CrCl2 + H2

Cr + H2SO4 ® CrSO4 + H2

4. With hot concentrated sulphuric acid it gives chromic

sulphate and liberates sulphur dioxide.

2Cr + 6H2SO4 ® Cr2(SO4)3 + 3SO2 + 6H2O

5. Dilute nitric acid does not attack the pure metal

while concentrated acid renders it inactive

or passive i.e., it does not show its usual reactions.

6. Action with Halogens : Chromium combines

directly with fluorine and dry chlorine to

give chromium (III) halides.

2Cr + 3F2 ® 2CrF3

2Cr + 3Cl2 ® 2CrCl3

Use : In chrome -

plating.

1. The articles to be plated with chromium are made the

cathode in an electrolytic bath

consisting of chromic acid and sulphuric acid while the anode is made of a plate of lead. During electrolysis chromium deposits

on the article (cathode).

Generally the articles are first plated with nickel and then subjected to chromium plating.

2. In the manufacture of alloy steels (e.g.) chrome steel,

chrome vanadium steel, stainless

steel and tungsten steel.

3. Chrome nickel steel is used for armour plates.

4. Chromium salts are used as mordants and in the

manufacture of coloured glass and pottery.

5. Chromium compounds are used in dyeing as pigments and in

tanning of leather.

Alloys of chromium

Alloy %

composition Uses

i) Ferrochrome -

Cr = 65% Fe = 35%

It is used in manufacture of chrome steel, burglar proof safe

ii) Stainless steel

Cr = 11-13%

C = 0.1 - 0.4%

Fe = 73% Ni = 8%

It is used for cutlery and house hold wares.

iii) Nichrome

Cr = 15%, Ni = 60%

Fe = 25%

It is used in resistance wires for electrical heating

iv) Stellite

Cr = 20-35%

Co = 40-80%

Ni = 0.25%

C = 0.75 - 2.5%

It is used in cutlery, surgical instruments,.....etc.

Related Topics