Chapter: Biotechnology Applying the Genetic Revolution: Pathway Engineering

Biorefining of Fossil Fuels

BIOREFINING

OF FOSSIL FUELS

The growth of industrial civilization, in particular the use of fossil fuels for energy and the development of the organic chemical industry, have led to the pollution of the environment with a wide range of compounds of nonbiological origin.

Many fossil fuel deposits, of

both coal and oil, contain a high percentage of sulfur—up to 5% sulfur for many

coals from Eastern Europe or the American Midwest. Burning high- sulfur coal

releases large quantities of sulfur dioxide into the atmosphere, which leads to

the formation of acid rain. Among the possible solutions to this problem is to

develop bacteria capable of removing the offending sulfur compounds from the

coal (or oil) before combustion.

Several naturally occurring

sulfur bacteria such as Thiobacillus

and Sulfolobus can convert pyrites

(FeS2) the major form of inorganic sulfur found in coal, into

soluble sulfate that can be rinsed away. The crucial issue, therefore, is to

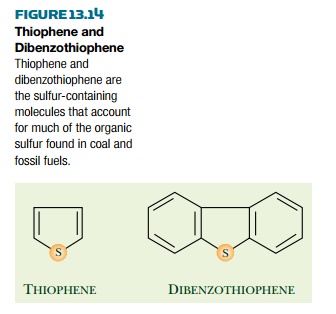

remove the organic sulfur, especially that found in thiophene rings, which typically accounts for 70% or more of the

organic sulfur (Fig. 13.14). Although compounds containing thiophene rings are

almost never found in modern-day living organisms, they form a substantial part

of the organic sulfur fraction of fossil fuels such as coal and oil. The major

quinone of Archaebacteria such as Sulfolobus

is caldariellaquinone, which contains a thiophene ring fused to a

benzoquinone. Conceivably, the fused

thiophenes of coal are the metabolic fossils of archaebacterial metabolism.

Dibenzothiophene (DBT) is a widely used model compound (Fig. 13.14) thought

to be representative of the organic

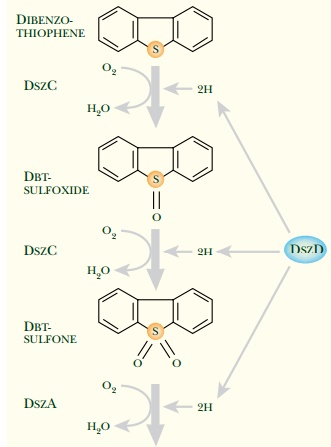

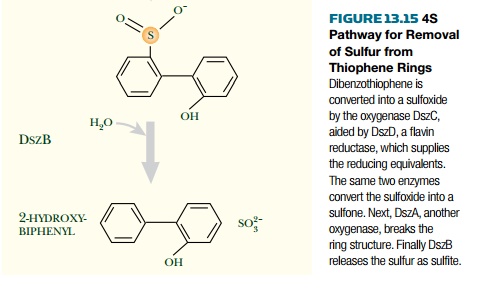

sulfur in coal and oil. Biodegradation of DBT and removal of sulfur involves

several steps, a scheme known as the 4S

pathway (Fig. 13.15). Most bacteria capable of degrading thiophene

derivatives show only partial breakdown. Many do not completely remove the

sulfur from its organically bound form, and others only use DBT that has

already been oxidized to the sulfone or sulfoxide level (see Fig. 13.15). Full

desulfurization requires

either finding a natural isolate that can carry out all the steps or the

genetic assembly of the individual steps of the 4S pathway from different

bacteria into a final engineered strain.

Certain bacteria, especially

certain species of Rhodococcus, do indeed completely desulfurize

dibenzothiophene, as well as degrade related heterocyclics such as dibenzofuran

and xanthones. The dszABC operon of Rhodococcus is found on a linear plasmid

and encodes three enzymes responsible for the 4S pathway. In addition a flavin

reductase encoded by the dszD gene is

needed to supply reduced FMN (see Fig. 13.15). The dszD gene is not linked to the dszABC

operon. The enzymes are as follows:

■

Third step: DszA = dibenzothiophene sulfone oxygenase

■

Fourth step: DszB = benzene sulfinate desulfinase

■

First and second steps: DszC = dibenzothiophene oxygenase

■

FMNH2 supply:

DszD = flavin reductase

However, there are several problems with these

natural isolates:

(a) Rhodococcus

is not well characterized genetically, so further modification is difficult.

(b) Desulfurizing

coal or oil will require robust bacteria that can be grown easily to high

density. Although not feeble, Rhodococcus is not especially convenient in this

respect.

(c) The

desulfurizing genes (dszABC) in Rhodococcus are used naturally to obtain sulfur

(not to degrade benzothiophenes for carbon and energy).

Consequently, they are expressed only at a low

level for bacterial growth. Moreover, other sulfur compounds, both inorganic

and organic, repress the operon. Thus, the inorganic sulfur present in most

high-sulfur coal and oil would repress the dszABC genes. Furthermore, pregrowth

of the dibenzothiophene and related compounds. In these cases, the same enzyme

hydroxylates the aromatic rings and also adds oxygen to the thiophene sulfur,

giving the sulfoxide and then the sulfone. The DszC enzyme itself has also been

mutated to High-level operation of the

4S pathway requires a large flow of reducing equivalents. In cells carrying a

cloned dszABC operon, reduction of FMN by flavin reductase becomes the limiting

factor in removal of sulfur from dibenzothiophene. However, flavin reductases

from several other bacteria work as well as or better than the Rhodococcus DszD

enzyme. For example, the HpaC enzyme from E. coli has been cloned and expressed

at high levels, and it greatly speeds desulfurization. As a further

modification, the hpaC gene and the dszABC genes have been joined together to

form a single operon under control of the tac promoter. (This is a hybrid promoter with the RBS from the trp promoter and the operator of the lac promoter. It is therefore a strong

promoter that is induced by IPTG.) Thus the combined desulfurization module can

be induced by IPTG when required.

Despite adding oxygen to the

sulfur of dibenzothiophene, the DszC enzyme is closely related to the ring

dioxygenases that add two hydroxyl groups to aromatic rings.

Thus phenanthrene dioxygenase hydroxylates phenanthrene (a three-ringed aromatic hydrocarbon) as well as converting DBT to its sulfone. Again, mutation of biphenyl dioxygenase by a gene shuffling approach gives mutant enzymes capable of handling broaden its substrate range. For example, a Val261Phe mutation allows oxidation of methylbenzothiophene and alkyl thiophenes.

Related Topics