Chapter: Aquaculture Engineering : Design and Construction of Aquaculture Facilities

Water treatment department - Land-based hatchery, juvenile and on-growing production plant in Aquaculture Engineering

Water treatment department

In this

department the equipment to control and eventually improve the water quality is

installed. It is a very difficult department to design well, especially when

much equipment is needed (Fig. 21.13). In several established farms this

department looks a mess. When planning, it is important to allow sufficient

space. The department will, in all proba-

bility, be

changed and modified several times. It is advantageous to include several

valves in the system so that water flows can easily be stopped and sent in

different directions. It must be possible to remove all the individual pieces

of equipment without having to shut off the inlet water supply to the farm.

The amount of equipment

needed in this department varies with the quality of inlet water and therefore

the need to treat it. In this department equipment is typically installed for:

· Aeration

· Disinfection

· Oxygenation

· pH control

· Removal of

suspended solids

· Heating and

cooling.

If using a central re-use system,

the equipment for ammonia removal and the re-use pumps may also be placed here.

Before starting to plan a

water-treatment department on a new farm, it is always recommended that a flow

chart be drawn that includes the different free water surfaces to prevent

mistakes. It is quite normal to site the water treatment department in two

rooms, a machine room and a water treatment room. Equipment for oxygen

production together with equipment for heating and cooling can be placed in the

machine room. In the water treatment room there are large free water surfaces

and therefore high humidity, so proper ventilation is necessary here. Examples

of equipment placed in this room include that for aeration, ammonia removal and

solids removal. By having two rooms, the expensive mechanical equipment can be

placed in a separate room with lower humidity.

It is advantageous to locate some

equipment close to the water inlet or where the water transfer pipe to the

farms starts. This ensures some exposure time before the inlet water reaches

the farm. When using ozone as a disinfectant, or when adding chemicals for

changing the pH, it can be done in the inlet and the need for a large retention

basin inside the farm avoided.

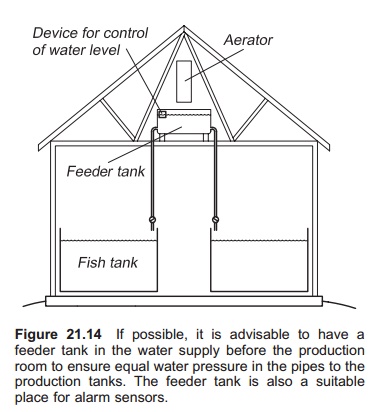

There are advantages in having a

feeder tank as a last step before the water reaches the production system. This

will ensure equal pressure in the inter-

nal pipelines. At the same time,

the pressure will not be too high. High pressure in the internal pipelines will

create a lot of noise in the pipes and valves in the production hall. In

addition, it may be necessary to use pipes and parts of a higher pressure

class, which is more expensive. A feeder tank is also a suitable place to

install the alarm sensors, because the level will immediately drop when there

is trouble with the water supply (Fig. 21.14); some reaction time is also

achieved if the water flowdrops, depending on the volume of the header tank.

The disadvantages of using a feeder tank are that it is necessary to lift the

water to a higher level, if no pressurized water is available. For this reason

sea-water is sometimes sent directly through channels or pipes into the

production room.

Related Topics