Chapter: Aquaculture Engineering : Heating and Cooling

Types of heat exchanger

Types of heat exchanger

When designing a heat exchanger the aim is to create a large area where exchange of energy between the two media can take place. Two types of heat exchangers are common in fish farming: plate, and shell and tube exchangers.

Plate exchangers

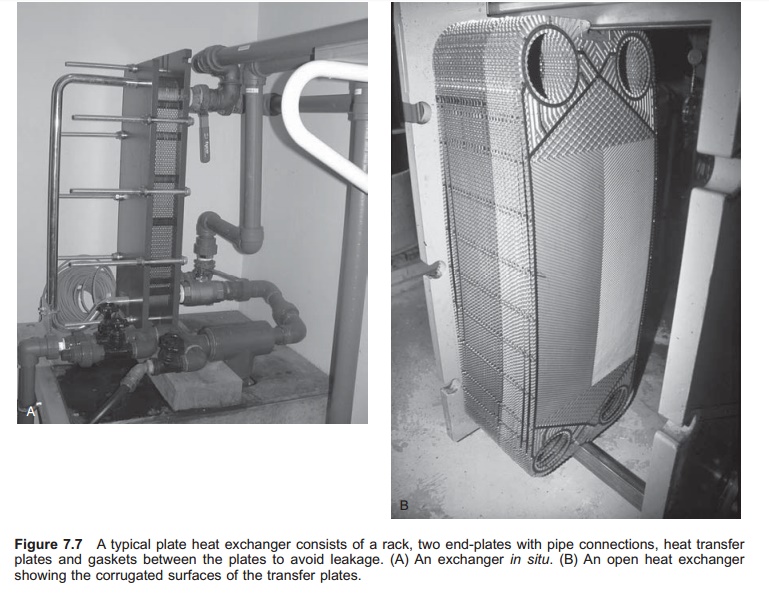

A common plate exchanger consists of the follow-ing components: a rack, two end-plates with pipe connection in one or both sides, the heat transfer plates and gaskets that are used between the plates to avoid leakage (Fig. 7.7). In plate exchangers that cannot be dismantled, it is possible to omit the gaskets and braze or solder the plates together instead. The two media flow into the exchanger at one end; the hot and cold water flow in two sepa-rate circuits divided by the heat transfer plates. Hot and cold water will flow in parallel through the whole length of the exchanger, assuming the coun-tercurrent principle is used as is usual. The size of the energy transfer area can be changed by adding and removing heat transfer plates as long as there is sufficient space in the rack. The exchanger can be opened to add or remove plates and for cleaning unless the parts are brazed together. The former type is normally used in fish farming because they are easy to open for cleaning and removal of fouling. The latter type can be used as evaporators and condensers in a heat pump, or in places where both the flowing liquids are pure and fouling of the heat transfer surfaces does not occur.

Some kind of corrugation on the heat transfer plates is normal (Fig. 7.7). This increases the area were heat transfer occurs and hence the NTU. In addition the corrugation will increase the turbu-lence and because of this improve the heat transfer, so increasing the value of k. The gasket between the plates which inhibits leakage, is either glued or clipped to the plates and made of a resis-tant rubber material.

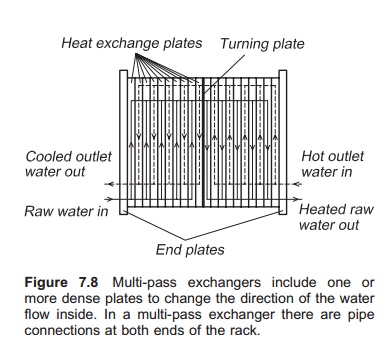

To increase the heat transfer area, several heat exchangers can be connected in series, one after another. The alternative is to use the so called ŌĆśseveral-strokeŌĆÖ exchanger. Normally an exchanger has one stroke, but by adding dense plates in the middle where the direction of the water flow is changed, a several-stroke exchanger is achieved (Fig. 7.8). The result is the same as adding two exchangers in series, but only one rack is used. Whether a plate exchanger is a one-stroke or several-stroke type can easily be seen from the connection points. A one-stroke exchanger has all pipe connections on one side to, one of the end-plates, while several-stroke exchangers have pipe connections on both sides to, both end-plates. To be able to dismantle a two-stroke exchanger, e.g. for cleaning, it must be possible to disconnect the pipe connections in a simple way.

The value of k for plate exchangers varies signif-icantly depending on the corrugation pattern on the surface; normal values are from 3.5ŌĆō8 kW/(m2 ┬░C). The plates are very thin, in the region of 0.5 mm.

Shell and tube exchangers

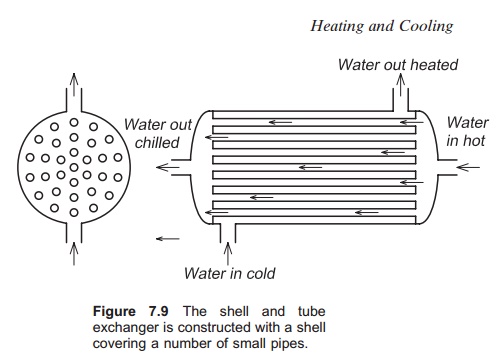

Another common type of heat exchanger is the shell and tube. This is widely used in condensers and evaporators in heat pumps and cold storage plants in fish farming. It is constructed with a shell cover-ing a number of small tubes (Fig. 7.9). The shell is normally a large tube. One medium flows in the small tubes while the other flows around the tubes, in the shell. The small pipes and the large pipe con-stitute the two different circuits where the two dif-ferent media flow and heat can be transferred. Shell and tube exchangers are seldom used for tradi-tional water-to-water heat exchange in fish farming because they are quite difficult to clean manually. They can be opened by removing the cap at one end of the shell, but it is impossible to reach all heat transfer surfaces for simple manual brushing. They must be adapted for automatic chemical cleaning.

Special types, pipes in seawater

A pipe that is laid down in water will have a higher or lower surrounding temperature than the water flowing through the pipe and will function as a heat exchanger. This principle has been used in fish farming. If the temperature in the surrounding water is higher, heat will be transferred into the water flowing inside the pipe. To obtain a noticeable temperature increase in the water flowing inside the pipe, the following factors are of importance: length of the pipe, temperature difference between the water inside the pipe and around the pipe, and the heat transfer coefficient (k) of the pipe mater-ial. This again depends on the thickness of the pipe, material of which the pipe is constructed, contact area between water and the pipe material on both sides, and the convection conditions inside and around the pipe.

In practice, plastic seems to be the material most often used. Polyethylene does not, however, trans-fer energy particularly effectively as it has, quite a low k value, but PE pipes are cheap and easy to lay.

The pipes must be moored; normally concrete blocks are used. If in seawater, it is normally to lay pipes at depths below 20ŌĆō30 m, too avoid the most critical depth that results in much fouling of the exterior surface. In fish farming the system may be used for heating freshwater in the winter. In this case the inlet pipeline must be laid into seawater where the temperature is normally higher than in freshwater. A substitute for a traditional on-shore heat exchanger where seawater is pumped through, is then achieved. What is found in practice is that the pipe has to be several hundred metres long to achieve a noticeable temperature increase. Depending on the site conditions and the geo-graphical distance between the site and the water source, this might be a good solution if the water transferred from the source to the fish farm is near the sea.

Related Topics