Chapter: Aquaculture Engineering : Heating and Cooling

Installations of heat pumps - Aquaculture Engineering

Installations of

heat pumps

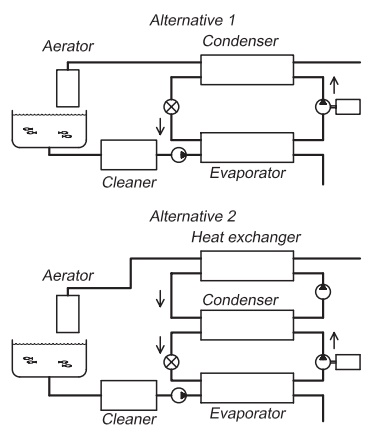

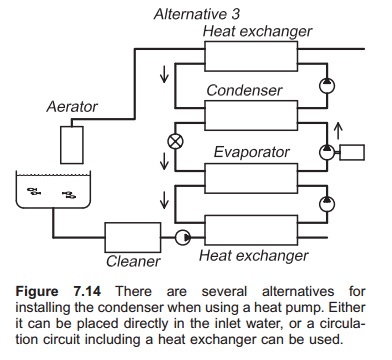

When installing a heat pump location of the condenser is

very important, because it is here that the energy is released. For a

refrigeration plant location of the evaporator will be important because here

removal of energy occurs. There are a number of places for installing the

condenser in the heat pump in a fish farm; all have advantages and disadvantages

(Fig. 7.14). One solution is to place it directly into the inlet water, which

gives very good heat transfer. However, leakage from the condenser could lead

to contamination of the inlet water by the refrigerant, which is dangerous

because it could be toxic to the fish. To avoid this, an extra closed circuit

is more commonly used between the con-denser and the inlet water consisting of

a pump and a heat exchanger through which a non-toxic liquid (water or glycol,

for instance) circulates. Glycol has a high thermal capacity so is a good

choice of medium. Between 10 and 15% reduction in the COP is normal when using

the extra circuit, because the heat is transferred twice.

Another method is to install the condenser in the outlet

water and afterwards have a heat exchanger between the outlet water and the

inlet water, also a two-step heat transfer process. The disadvantage with this

method is that increased fouling will present problems. Cleaning of the

condenser, which is normally of the shell and tube type, is difficult.

The evaporator is normally placed in the outlet water.

Here there will also be problems with fouling, and a closed circuit can also be

used to advantage in this situation. A plate exchanger is used in this circuit

to transfer the heat, because it is easier to open for cleaning.

When using the evaporator in the outlet water and the

temperatures are low freezing of the outlet water may be a problem because the

temperature is reduced as much as possible through the evapo-rator to recover

the stored energy in the outlet water, meaning that the temperature in the

working medium is 0°C or less to ensure effective heat transfer.

It is therefore possible that the water in the evaporator

will freeze, for instance if there is a reduction in the water flow or drop in

the inlet water temperature. To avoid breakage of a shell and tube evaporator

due to ice, it is normal to use glycol which functions in the same way here as

in the con-denser circuit; glycol is a liquid with a very low freezing point.

In practice, there is not usually enough energy in the

outlet water to get a heat pump to function with a good COP. Therefore the heat

pump will usually be an integral part of a total energy system where additional

energy from seawater or another low temperature source may be used. Energy may

also be added directly, for instance by using an immer-sion heater; this will

of course require a much smaller heater compared to using an immersion heater

alone and not in combination with a heat pump.

Example

Inlet water to a

fish farm is heated from 2 to 8°C by transfer of energy from the condenser. The

water flow is 500 l/min (8.33 kg/s). Fifty kW of electric energy is supplied to the compressor. Find the

COP for the heat pump.

Start by calculating

the total energy input to the inlet water:

P = mcpdt

= 8.33 kg/s × 4.2 kJ/(kg °C) × 6°C

=210 kJ/s

210 kW

The COP is

therefore

e = 210/50 = 4.2

This means that for

every kW of electric energy that is supplied to the compressor, the water is

heated by 4.2 kW.

Related Topics