Chapter: Aquaculture Engineering : Heating and Cooling

Factors affecting heat transfer - Aquaculture Engineering

Factors affecting

heat transfer

The rate of energy transfer (P)

of the heat exchanger depends on the temperature difference between the media,

the thermal conductivity of the material in the heat exchanger and the area

over which the energy is transferred; it can be calculated from the equation

P = kA LMTD

where:

k = heat transfer coefficient (W/(m2 ┬░C))

A = heat transfer area (m2)

LMTD = log mean temperature difference (┬░C).

The value of k gives

the quantity of energy trans-ferred per square metre surface area and degree

temperature difference. Various factors affect k; in practice, values of up to 8 kW/(m2 ┬░C) are

achieved. kcan be calculated from the

following equation:

Here, a1 and a2 are the heat transfer coefficients

on each side of the material in the heat exchanger. They give the quantity of

energy transferred from a liquid or gas to or from unit area of a fixed

mate-rial and per degree temperature difference. The values depend on the

condition for convection and conduction and can be improved by optimizing

operational conditions.

tp is the thickness of the material that

separatesthe two flowing media; increasing tp

will decrease k because the heat must

be transported a greater dis-tance through the fixed material. Use of a thin

fixed material results in a low k

value.

l is the heat convection factor for the

material;steel and other metals have a high factor, while glass and plastics

have a lower factor. This why metal with good conductivity is used for the heat

transfer plates.

Rf is the fouling factor, which gives

the amountof fouling on the material of the heat transfer plates. Fouling

reduces k, and therefore the rate of

energy transfer will be reduced. High turbulence close to the surface of the

heat transfer plates will reduce the amount of fouling, in addition to improving

a1 and a2. Cleaning of the

exchange sur-faces will also reduce the fouling, Rf. The reduction in k

is because the conductivity of the layer of fouling is low and the thickness of

the transfer material is increased.

Manufacturers of heat exchangers normally give kA as a single value. This is because

each manufac-turer will have their own design for the heat transfer area to

create optimum flow with turbulence; to improve conditions for turbulence and

increase the heat transfer area, various patterns are used on the exchange

surface, including grooves and corrugations.

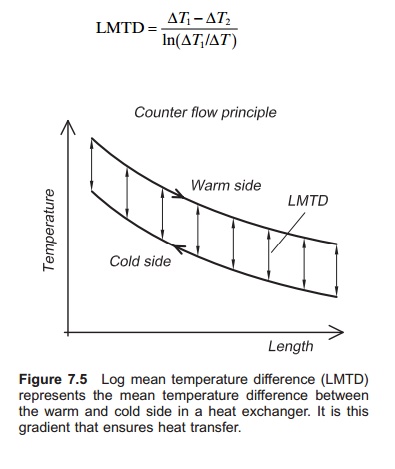

The temperature gradient between the warm and the cold side in

the exchanger (Fig. 7.5) ensures energy transfer. It is expressed as the LMTD.

A log-arithmetic expression is used because temperature equalization between

the media through the exchanger may not be linear. LMTD can be calcu-lated from

the following equation:

where:

T1=tin(hot water)ŌłÆ tout(heated water)

T2=tout(cooled water)ŌłÆ tin(water to be heated).

If the amount of water and the heat exchange area are the same

on both sides of the heat exchanger, ŌłåT1= ŌłåT2=LMTD. LMTD will vary depending onwhether it

is a parallel-flow

or counterflow exchanger.

Related Topics