Chapter: Aquaculture Engineering : Heating and Cooling

Important parameters when calculating the size of heat exchangers - Aquaculture Engineering

Important parameters when calculating the size of heat exchangers

Number of transfer units

Number of transfer units (NTU) indicates how much energy can be transferred per unit LMTD. Indirectly, it gives an idea of what the exchanger will look like, its size, etc. The following calculation can be used to find the NTU of the exchanger:

NTU = (tinŌłÆtout)/LMTD

where

NTU = number of transfer units

tin = temperature of water flowing into theexchanger

tout = temperature of water flowing out of theexchanger

LMTD = log mean temperature difference (┬░C).

Example

Calculate the NTU for the warm side in a heat exchanger, i.e. the side where the hot water is chilled. Water flows into the exchanger at 1000 l/min at a tem-perature of 10┬░C and out at 4┬░C; the LMTD is 1.5┬░C.

NTU = 10 -4 /1.5 = 4

The NTU can be calculated both for the warm and cold side of the exchanger. Depending on the flow conditions and the transfer area, it could be the same (if the flow and heat transfer area are the same on both sides of the exchanger).

In a plate exchanger described in section 7.5.5 the NTU is seldom above 5, or the plates will be unreasonably large. If the LMTD is estimated and the NTU known, the highest possible out tempera-ture that can be reached can be calculated. If NTU is above 5, heat exchangers can be connected in series, or several-stroke exchangers can be used.

The design of the heat exchange surface area varies. A closed design results in a large NTU with good heat transfer but a high head loss, whereas a more open design results in a lower NTU.

Specific pressure drop

The pressure drop in the liquid flowing through the exchanger is necessary to achieve heat transfer. If a high head loss through the exchanger is accepted, the size of the exchanger can be reduced. Higher pressure creates more turbulence and improved contact between the exchange plates, but a higher input pressure to the exchanger is necessary.

The specific pressure drop (J) for a heat exchanger gives the pressure loss for every transfer unit, and can be represented by the following equation:

where:

J= specific pressure drop

ŌłåP =total head loss through the exchanger

NTU = number of transfer units.

The economic optimum head loss through the heat exchanger varies depending on the situation and has to be calculated in every case. Normally it lies in the range 2ŌĆō10 mH2O per NTU for exchangers used in fish farming. When looking at the different areas where exchangers are used, the following approximate specific pressure drop per transfer unit can be used as an approximate base to start a simulation process to optimize the size of a plate heat exchanger:

┬Ę Seawater exchanger 5ŌĆō10 mH20

┬Ę Outlet water exchanger 10ŌĆō12 mH20

┬Ę Evaporator in a heat pump 3 mH20

┬Ę Condenser in a heat pump 4 mH20

Other important measurements

The maximum pressure (design pressure) in heat exchangers used in fish farming is normally in the range 1ŌĆō2 MPa or 10ŌĆō20 mH2O. Usually the plate exchangers have up to 2000 m2 of exchange surface area and the water flow can be 1000 l/s or more.

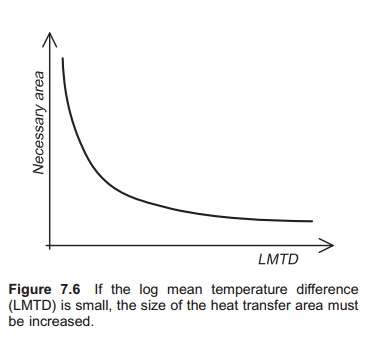

Exchanger price of course depends on size: a large exchanger will cost more than a small one. If higher head loss can be accepted the size of the exchanger can be reduced. Also the size of the LMTD is of great importance. If a small LMTD is needed the size of the exchanger will increase (Fig. 7.6).

When installing a heat exchanger, the energy profit must therefore always be evaluated against the price of the exchanger. To have a low LMTD is normally very costly. The necessary transfer area, or size of the exchanger increases when the LMTD is reduced. Suppliers of equipment normally have their own programs to simulate the temperature of water discharged (their own kA values) to optimize the size of their exchangers.

Related Topics