Chapter: Aquaculture Engineering : Heating and Cooling

Fouling - Aquaculture Engineering

Fouling

Fouling is a problem with the use of heat exchangers in

fish farming. This occurs particularly when using outlet water on one side in

the exchanger, but there are also problems associated with using sea-water on

one side. Fouling of the transfer surfaces will reduce the value of k and the heat transfer. Fouling will

cover the transfer surfaces, and the conduction through the layers of fouling

is dra-matically reduced compared to surfaces with no fouling. Since fouling

occurs normally and it is impossible to remove it continuously, this must be

taken into consideration when designing heat exchangers for use in fish

farming. This is done by including the fouling factor (Rf) in the calculations which again decreases the value of k .

It is important to reduce the amount of fouling as much as

possible, but of course within economic limits. Washing of the surfaces will

reduce the fouling, whether by the use of chemicals, manual brushing, or both.

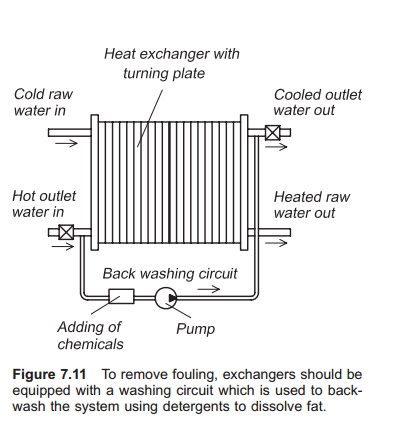

To make chemical washing pos-sible in a simple way, the exchangers should be

equipped with a backwashing circuit (Fig. 7.11). For the washing procedure the

heating system is stopped and the exchanger backwashed several times with water

containing a detergent: caustic

soda or lye may be used as a detergent in fish farming.

Chemical washing, however, is normally not enough and the exchangers have to be

opened and the heat transfer surfaces brushed manually. It may not be necessary

to do this every time, but only for some of the washings, for example once a

week. This of course depends on the degree of fouling which varies with the

characteristics of the water flowing through the exchanger, i.e. whether it is

new water or outlet water.

When cleaning the exchangers the heating system must be

switched off. Because of this, it can be advantageous to have at least two

exchangers, so at least half the heating capacity is functioning during the

cleaning procedure. It is important to have enough valves in the pipelines to

be able to change the flow direction to permit this.

The degree of fouling decreases with increased water

velocity through the exchanger, because more turbulence is created. However,

this will also increases the head loss, so there is a balance to finding the

optimal water velocity. What is cer-tain is that a low velocity through the

exchanger increases the degree of fouling; this will occur if the water flow

through the exchanger is reduced compared to what it is designed for; in the

worst cases total blockage of the exchanger can result. The normal water

velocity through exchangers is around 2 m/s.

Fungus clots and larger particles may block the exchanger

totally. To reduce the risk of blockage, for instance when using outlet water,

the water must always be filtered before entering a heat exchanger. This will

to some extent, also help to reduce the amount of fouling. A particle removal

filter, for instance a rotating screen filter, is commonly used for this

purpose.

Related Topics